Uniaxial and Multiaxial Plastic Deformation of Large Niobium Grains

advertisement

Uniaxial and Multiaxial Plastic

Deformation of Large Niobium

Grains

Thomas Gnäupel-Herold1,2,

Adam Creuziger, T.Foecke3

of Maryland

Center for Neutron Research

3NIST Metallurgy Division

2NIST

1University

Formability: strain localization

on grain boundaries

up to 0.5 mm displacement

found between neighboring

grains

Plastic Properties of Niobium

BCC Crystal Structure

< 111 > slip direction (close-packed direction)

Any plane containing < 111 > is a potential slip plane

Experimentally observed in (110), (112) & (123) planes

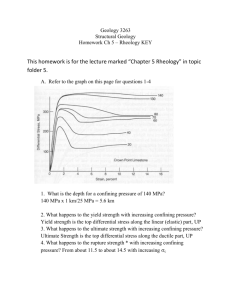

Tensile Tests

Orientations

Tensile Tests

111

250

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S12

S13

S14

S15

S5

S16

S4

S6

true stress [MPa]

200

S3

S2

S1

S9

S14

100

150

S10

S7

S12 S13

S8

S17

110

100

50

0

0

0.2

0.4

0.6

strain

0.8

1

Yield Stress

Polycrystal

Single crystal

YS between 25

MPa and 40 MPa

weak anisotropy

25% YS of polycrystal

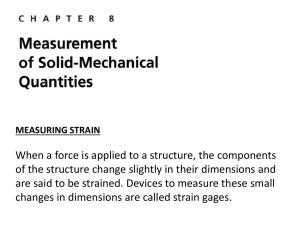

R-Values

w

R

t

R-values

1.2

1.0

R

0.8

0.6

0.4

0.2

0.0

g1 g2 g3

g4 g5 g6

g7 g8

g9 g10 g12 g13 g14 g15 P1 P2 P3

Specimen

Extreme anisotropy

from r=0 (thinning

only) to r>1 (no

thinning)

Polycrystal r=0.1

Large r-values for

{210}<-120>

Effect of Annealing

250

120

(1),<100>,1000C

(3)

(2),<111>, 1000C

(3),<110>,1000C

(2)

true stress [MPa]

true stress [MPa]

200

(1)

(4),<211>, 700C

(5),<100>, 700C

150

(2)

100

(4)

50

80

(1)

(5)

(4)

40

(5)

(3)

0

0

0

0.2

0.4

0.6

0.8

1

0

0.01

strain

•Yield stress and yield drop increase with

annealing temperature

0.02

0.03

strain

0.04

0.05

Sample prep for multiaxial tests

Multi-axial Testing

A - Uniaxial Test

B - Uniaxial Test, 90 deg rotated

C - Balanced Biaxial Test

D - Plane Strain

localization

E - Plane Strain, 90 deg. rotated

E – Plane Strain

EBSD: Misorientations at the tri-junction

•Slip lines and smallangle grain boundaries

•Diffuse slip, most

likely from rapidly

changing strain

gradients leading to

succession of

activation/deactivation

of localized slip

systems

Analysis of present data

What is known ….

What is needed …

Slip

systems

that

are

Full strain rate

locally active at a

tensor at every point

given point in time

on the sample and

in time

orientations

Taylor’s model

Imposed strain rate

tensor

ε11

ε 12

ε

2

ε 13

2

ε 12

2

ε 22

ε 23

2

- ε 11 ε 22

ε 13

2

ε 23

2

Write the strain rate

tensor as a

γ α α

α

α

α

ε

m

n

n

m

α 2

combination of all

the slip systems

Conclusions

5 Multi-axial straining tests of tri-crystal

plates with identical orientation

performed

Local strain rate data collected

Orientation analysis with EBSD

GOAL: determination of locally active slip

systems for any given moment