What is an Electron Microscope - Department of Science and

advertisement

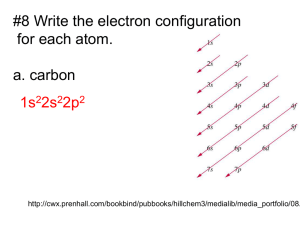

What is an Electron Microscope? The development of the Scanning Electron Microscope in the early 1950's brought with it new areas of study in the medical and physical sciences because it allowed examination of a great variety of specimens. As in any microscope the main objective is for magnification and focus for clarity. An optical microscope uses lenses to bend the light waves and the lenses are adjusted for focus. In the SEM, electromagnets are used to bend an electron beam which is used to produce the image on a screen. By using electromagnets an observer can have more control in how much magnification he/she obtains. The electron beam also provides greater clarity in the image produced. A modern version of the SEM. The first modern scanning electron microscope, constructed by D. McMullan in the Cambridge University Engineering Laboratory in 1951. Source: Electron Optics and Electron Microscopy, P.W. Hawkes. The SEM is designed for direct studying of the surfaces of solid objects. By scanning with an electron beam that has been generated and focused by the operation of the microscope, an image is formed in much the same way as a TV. The SEM allows a greater depth of focus than the optical microscope. For this reason the SEM can produce an image that is a good representation of the threedimensional sample. How the SEM Works The SEM uses electrons instead of light to form an image. A beam of electrons is produced at the top of the microscope by heating of a metallic filament. The electron beam follows a vertical path through the column of the microscope. It makes its way through electromagnetic lenses which focus and direct the beam down towards the sample. Once it hits the sample, other electrons ( backscattered or secondary ) are ejected from the sample. Detectors collect the secondary or backscattered electrons, and convert them to a signal that is sent to a viewing screen similiar to the one in an ordinary television, producing an image. How an Image is Produced To produce an image on the screen, the electron beam scans over the area to be magnified and transfers this image to the TV screen. The electron beam stops at 1,000 points as it scans horizontally across the sample and down 1,000 lines vertically. This gives 1,000,000 points of information. The signal read from the electrons coming off each point is transfered to a corresponding point on the TV screen. Since the TV screen also has 1,000 points horizonally and 1,000 lines vertically, there is a 1:1 correspondance between the scan on the specimen and the TV screen. Since the length of the electron beam scan on the specimen is smaller than the length of the TV screen, a magnification is produced equal to the following equation: Length of TV scan Magnification = Length of Electron Beam Scan By changing the size of the scan on the sample, the magnification can be changed. The smaller the area of the electron beam scan, the higher the magnification. Obtaining different degrees of magnifications are important in any practical uses of the SEM. Electron Beam/Specimen Interactions While all these signals are present in the SEM, not all of them are detected and used for information. The signals most commonly used are the Secondary Electrons, the Backscattered Electrons and X-rays. Backscattered Electrons When the electron beam strikes the sample some of the electrons will interact with the nucleus of the atom in much the same way a space craft will interact with the gravity of a planet. The negatively-charged electron will be attracted to the positive nucleus but if the angle is just right instead of being captured by the "gravitational pull" of the nucleus it will circle the nucleus and come back out of the sample without slowing down. These electrons are called backscattered electrons because they come back out of the sample. Because they are moving so fast, they travel in straight lines. In order to form an image with BSE (backscattered electrons), a detector is placed in their path. When they hit the detector a signal is produced which is used to form the TV image. All the elements have different sized nuclei. As the size of the atom nucleus increases, the number of BSE increases. Thus, BSE can be used to get an image that showed the different elements present in a sample. Secondary Electrons and Detection Sometimes beam electrons interact with the electrons present in the atom rather than the nucleus. Since all electrons are negatively charged, the beam electrons will repel the electrons present in the sample. This interaction causes the beam electrons to slow down as it repels the specimen electrons, The repulsion may be so great that the specimen electrons are pushed out of the atom, and exit the surface of the sample, these are called secondary electrons. Unlike the BSE, the secondary electrons are moving very slowly when they leave the sample. Since they are moving so slowly, and are negatively charged, they can be attracted to a detector which has a positive charge on it. This attraction force allows you to pull in electrons from a wide area and from around corners in much the same way that a vacuum pulls in dust particles. The ability to pull in electrons from around corners is what gives secondary electron images a 3-dimensional look. Source: Iowa State MSE Department, http://mse.iastate.edu/microscopy/ For a more advanced description see the same source. Energy Dispersive X-ray analysis EDS Spectrum for contamination on stainless steel mesh. DESCRIPTION OF TECHNIQUE Energy dispersive x-ray spectroscopy (EDS) is a chemical microanalysis technique performed in conjunction with a scanning electron microscope (SEM) . The technique utilizes x-rays that are emitted from the sample during bombardment by the electron beam to characterize the elemental composition of the analyzed volume. Features or phases as small as about 1µm can be analyzed. When the sample is bombarded by the electron beam of the SEM, electrons are ejected from the atoms comprising the sample's surface. A resulting electron vacancy is filled by an electron from a higher shell, and an x-ray is emitted to balance the energy difference between the two electrons. The EDS x-ray detector measures the number of emitted x-rays versus their energy. The energy of the x-ray is characteristic of the element from which the x-ray was emitted. A spectrum of the energy versus relative counts of the detected x-rays is obtained and evaluated for qualitative and quantitative determinations of the elements present in the sampled volume. TYPICAL APPLICATIONS Surface contamination analysis Corrosion evaluations Coating composition analysis Rapid material alloy identification Small component material analysis Phase identification and distribution Source: http://www.mee-inc.com/eds.html Examples: Jämförelse av spår på kula hittad på brottplatsen med kula avfyrad från ett misstänkt vapen. Tjocklekmätning av tunna skikt Grundämnes analys längs en linje. Denna metod används också för tjockleksmätning av tunna skikt.. Brott av lödbump i BGA ESD-tyg med metalledare Tvärsnittsbild på billack komponent brott orsakad av icke tillräcklig mängd lodpasta . Slitage på guldbelagt kontakterings pinne (SEM bild) (topp vy) Kontakterings pinne (optisk mikroskop bild) (sid vy)