Experimental setup and pressure calculations

advertisement

Microstructural fingerprints of phase transitions in shock-loaded iron

S.J. Wang1, M.L. Sui2,*, Y.T. Chen3, Q.H. Lu1, E. Ma4, X.Y. Pei3, Q.Z. Li3, and H.B. Hu3

1

Shenyang National Laboratory for Materials Science, Institute of Metal Research, Chinese

Academy of Sciences, Shenyang 110016, China

2

Institute of Microstructure and Property of Advanced Materials, Beijing University of

Technology, Beijing 100124, China

3

Institute of Fluid Physics, China Academy of Engineering Physics, Mianyang 621900,

China

4

Department of Materials Science and Engineering, Johns Hopkins University, Baltimore,

Maryland 21218, USA

Supplementary Materials Includes:

Figs. S1, S2, S3, S4, S5, S6.

Tables S1, S2, S3.

Fig. S1: Microstructure of the whole shocked α-Fe grain for Fig. 2a. It includes 58

bright-field TEM images. A number of needle-type colonies mainly along two directions are

seen in the grain. The white line shows the grain boundary. Across the grain boundary, the

needle-type colonies in the neighboring grains present different orientations.

Fig. S2 One of the original TEM images of Fig. 2a without the demarcation line on the

needle-like regions. The enlarged detail shows the clear boundaries of the needle-like colony.

The red arrow indicates a small-angle boundary. Its SADP is presented in the inset.

Fig. S3: Microstructure of a shocked grain with the shock pressure direction deviating

from [001]bcc by a large angle of 30°. PTZ stands for the phase transition zone. D112T and

D332T stand for {112} and {332} deformation twins, respectively. The red arrow stands for

the projection direction of shock pressure in the observed (110)bcc plane.

In this grain, both plastic deformation and phase transition occur. The deformation twins form

along the (1-12)[-111]bcc system, for which the Schmid factor (0.39) is high, whereas phase

transition with characteristic threefold symmetry occurs only along the (-112)bcc plane

(Schmid factor is as low as 0.08 for (-112)[1-11]bcc ). For the deformation twins, the

maximum tilt angle φ of (1-12)T and (1-12)M planes is less than 2°, which is very different

from those stemming from phase transition with φ≈5°.

With the shock pressure different in every single grain in polycrystalline iron, the

morphology of the needle-like microstructure is different, but the phase transition characters

and phase transition mechanism remain the same.

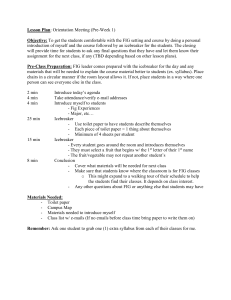

Fig. S4: Experimental setup. (a) A schematic of the iron hollow cylindrical sample under

shock wave. (b) A top-view schematic of the hollow cylinder under shock-loading. The shock

wave proceeds in the radial direction of the cylinder, labeled by the purple arrows. A VISAR

was used to record the inner free surface velocity. (c) A top-view image of the experiment

setup before filling PETN.

Fig. S5: The inner free surface velocity recorded by VISAR equipment.

Fig. S6 Pressure calculations. (a) The calculated pressure history of the points at 4.6, 1.9,

1.2 mm in the experiment. (b) The inner free surface velocity curve from the calculation, in

comparison with the experiment.

The details of the statistical analysis on the angle φ and volume fraction transformed (F).

The angle φ values in Table S1 are measured in twenty diffraction patterns which were

obtained from boundaries of needle-like colonies. Statistical analysis gives the mean value

and standard deviation value. Table S2 shows the F value measured from several different

grains in the locations at radius ~1.2 mm. The corresponding peak pressure here is ~14.2 GPa.

Table S3 shows the measured F at ~1.9 mm, ~13.3 GPa.

The angle φ measured in twenty diffraction patterns.

Table S1

φ (°)

4.9

5.6

5.8

5.4

4.5

5.4

4.2

5.0

5.3

5.3

4.2

4.3

6.0

5.9

4.2

4.7

5.3

6.7

6.2

4.6

Table S2

52.3

53.8

59.2

Table S3

53.6

54.9

58.6

28.2

5.175

0.72684

54.7

mean

standard deviation

54.5625

3.18969

Measured F at ~1.9 mm (~13.3GPa).

F (under ~13.3 GPa, %)

27.3

standard deviation

Measured F at ~1.2 mm (~14.2 GPa).

F (under ~14.2 GPa, %)

49.4

mean

23.1

26.3

30.7

mean

standard deviation

27.12

2.77705