5th International DAAAM Baltic Conference

"INDUSTRIAL ENGINEERING – ADDING INNOVATION CAPACITY OF LABOUR

FORCE AND ENTREPRENEURS"

20–22 April 2006, Tallinn, Estonia

SYNTHESIS OF VIBRO-CUTTING SYSTEMS WITH TIME AND

ADAPTIVE CONTROL

Akinfiev, T., Armada, M. & Viba, J.

Abstract: Synthesis and production

of real vibro-technical systems must take

into account all kinds of parameters

variations: – change of machine

mechanical parameters; – change of

processing media parameters; – change of

machine control system parameters. For

this reason systems with stable control

may be used. In this paper all kinds of

parameters changes were investigated for

synthesis vibro-impact cutting systems. The

main

problem

of

synthesis

new

technological systems is to provide they

motion stability.

Key

words:

impact,

technological

processing, motion stability, adaptive

control, synthesis.

parameters is investigated for adaptive

control of spring stiffness or excitation

forces.

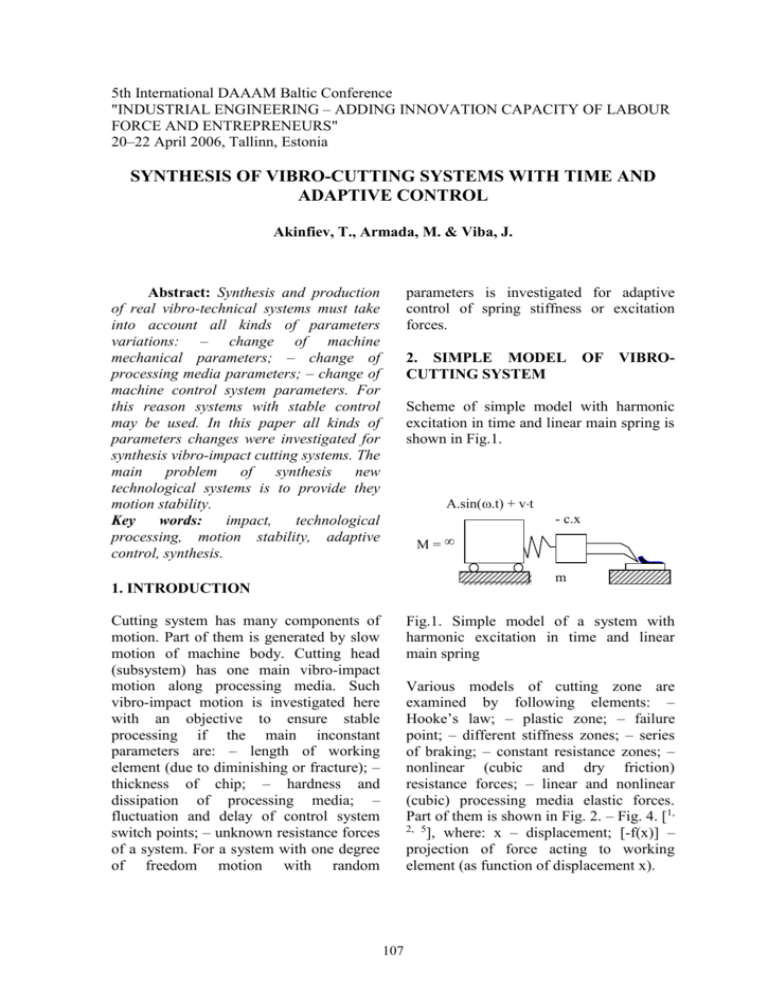

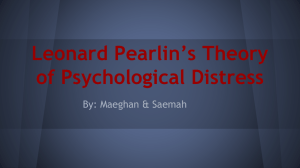

2. SIMPLE MODEL

CUTTING SYSTEM

OF VIBRO-

Scheme of simple model with harmonic

excitation in time and linear main spring is

shown in Fig.1.

A.sin(.t) + vt

- c.x

M=

m

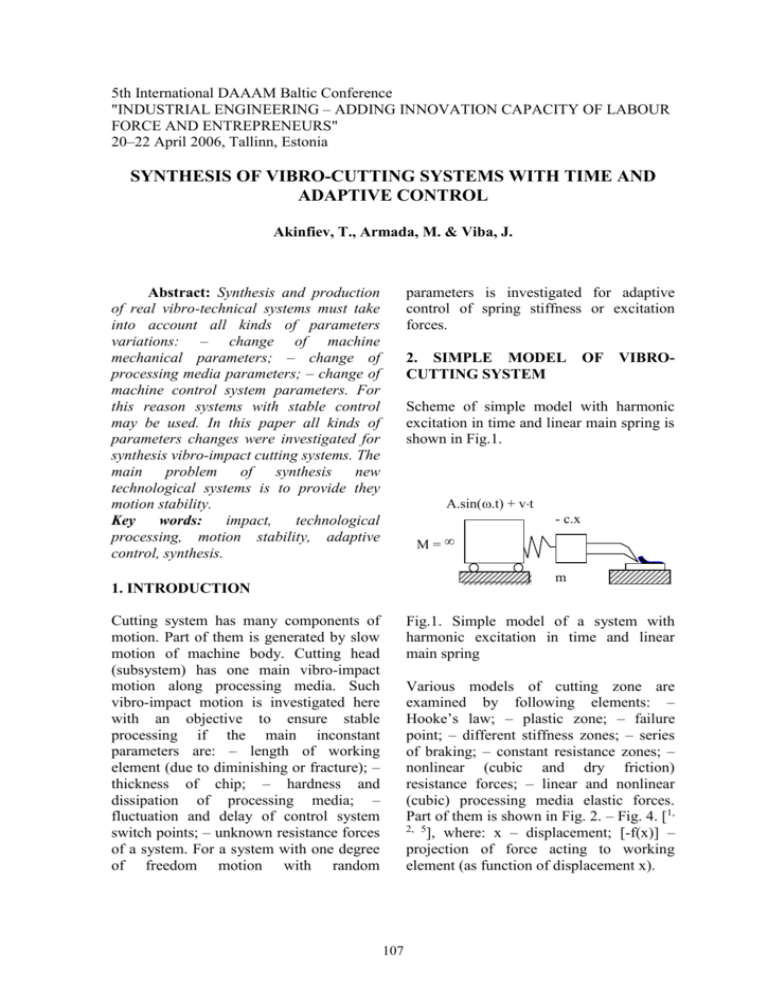

1. INTRODUCTION

Cutting system has many components of

motion. Part of them is generated by slow

motion of machine body. Cutting head

(subsystem) has one main vibro-impact

motion along processing media. Such

vibro-impact motion is investigated here

with an objective to ensure stable

processing if the main inconstant

parameters are: – length of working

element (due to diminishing or fracture); –

thickness of chip; – hardness and

dissipation of processing media; –

fluctuation and delay of control system

switch points; – unknown resistance forces

of a system. For a system with one degree

of freedom motion with random

Fig.1. Simple model of a system with

harmonic excitation in time and linear

main spring

Various models of cutting zone are

examined by following elements: –

Hooke’s law; – plastic zone; – failure

point; – different stiffness zones; – series

of braking; – constant resistance zones; –

nonlinear (cubic and dry friction)

resistance forces; – linear and nonlinear

(cubic) processing media elastic forces.

Part of them is shown in Fig. 2. – Fig. 4. [1,

2, 5

], where: x – displacement; [-f(x)] –

projection of force acting to working

element (as function of displacement x).

107

0.5

- f x( )

vn

x

Fig. 2. Model of a cutting zone f(x) with

full main spring (Hooke’s law) and

triangular damping loop or mechanical

hysteresis [5].

0

0.5

0.03

0.02

0.01

0

0.01

xn

- f(x)

Fig. 5. Motion in phase plane (v – velocity;

x – displacement) with zero gaps.

Transient process is very short (about 3

cycles)

0.5

x

Fig. 3. Model of cutting zone with one –

side main spring and triangular mechanical

hysteresis

vn

0

f (x)

0.5

0

1

2

3

tn

Fig. 6. Velocity v in time t domain with

zero gaps

x

Fig.4. Model of cutting zone with full main

spring and quadrangle mechanical

hysteresis

3.

SYSTEM

EXCITATION

WITH

MIXED

Investigation of a system includes special

solutions with excitation due to parametric

stiffness variation, and force excitation for

one degree of freedom system together

with additional displacement of cleaning

head, additional deformations of working

element and breaking adherence (Fig. 7.).

The simple equation of motion is (1) [1, 2]:

The fluctuation in time of a control action

was investigated in a case when system has

zero gaps (Fig. 5, Fig. 6.). Investigations

show that for real systems it is

recommended to choose positive initial

gap.

108

C3

2

[1 A sin( p t )]} x b13 x

mx {C1 C 2

C 4 x b4 x 3

F 0 sign ( x )

4

[1 sign ( x)] [1 sign ( x )]

P0 sin( t ),

1

1

0.726723

0.5

(1)

v

n

0

0.415695

where m - mass; x - displacement; x velocity; x - acceleration; C1, C 3, C 4,

stiffnesses of springs; C2 constant of

additional stiffness variation; A, p, b13,

F0, b4, P0 – constants. Examples of

modeling are shown in Fig. 8. – Fig. 11.

0.5

0.06

0.04

0.047421

0.02

0

0.02

x

3

n 3.944521 10

Fig. 9. Motion in phase plane in a case of

second resonance

1.084859

Robot Cleaning head

co+c1.sin(w1t)

v

n

0.5

Psin(wt)

0

0.452465 -0.5

Fig. 7. Scheme of system with mixed

excitation

0

0

1

2

t

3

n

Fig. 10. Velocity in time domain in main

resonance

0.63577

1

0.5

0.5

v

n

v

0

n

0

0.5

0.367174 0.5

0.04

0.04

0.02

0

0

x

n

0.02

3

3.437228 10

0

Fig. 8. Motion in phase plane in a case of

third resonance.

1

2

t

n

3

2.1

Fig. 11. Velocity in time domain in 0.25

resonances

109

parameters the equation of motion is the

same with difference that some parameters

are changing in time randomly. For small

exchanges the motion is stable, too (Fig.

15, Fig. 16).

4. SYSTEM WITH ADAPTIVE

CONTROL OF STIFFNESS

Scheme of system is shown in Fig. 12.

C1+C2

P0

C3

x

vx

C1

C1+C2+C3

x=0

F

C1+C3

x

O

C1+C3

Fig.12. Scheme of system with adaptive

control of stiffness by constant C2 (see

equation (2) and Fig. 13.)

C1+C2+C3

Equation of motion is following (2):

Fig. 13. Scheme of motion and

control ( x, x ) in phase plane (see (3))

mx {C1 C 3 ( x, x )) x b13 x

F 0 sign ( x )

(C 4 x b4 x 3 ) (a rnd (b))

4

[1 sign ( x )] [1 sign ( x )]

P0,

(2)

0.2

0.1

vn

where m - mass; x - displacement; x x

velocity;

acceleration;

C1,C 3 stiffness of springs; P0 constant force given by the springs initial

tensions or cleaning head weight ; - gap

when x = 0; ( x, x ) - control action; b13,

F0, C4, a, b – constants.

For adaptive control (excitation) as

change of common spring system stiffness

( x , x ) was used as function (3) (see Fig.

13.):

0

0.1

0.2

0.02

0.01

0

0.01

0.02

xn

Fig. 14. Modeling motion in phase

plane without random parameters.

Trajectories in the phase plane do not cross

and transient process is very short

0.2

C2

x x

(1

),

(3)

2

x x

where C2 - constant.

Example of motion is shown in Fig. 14. –

Fig. 16.

Motion character analysis allows conclude

that trajectories in the phase plane do not

cross and transient process is very short.

For modeling systems with random

0.1

( x , x )

vn

0

0.1

0.2

0.02

0.01

0

0.01

0.02

xn

Fig. 15. Motion in phase plane with

random parameters of cutting zone.

110

Trajectories in the phase plane do not cross

and transient process is very short

Comments about some investigation of

system are given under Fig. 18. – Fig. 21.

In the first part of motion a period exists

when vibro-impact motion increases.

After removal of the stick the second

period of vibration stop exists.

The periodic trajectory is not so irregular.

0.2

0.1

vn

0.5

0

x

n

0

0.1

0.5

0.2

1

0

5

0

10

5

t

tn

Fig. 16. Velocity in time domain

with random parameters of cutting zone

Fig. 18. Displacement of main mass in

time domain

5. SYSTEM WITH ADAPTIVE

CONTROL FOR NON-PERIODICAL

CYCLE

3.005351

3

v

n

Scheme of removal of defected adhered

blocks from main reinforced concrete

production line is shown in Fig. 17 [3, 4].

After technological cutting process a part

of the block sticks to steel plate. Attempt

to remove block by simple winches may

damage a block in vertical direction near

holes.

In this report adhered blocks problem is

solved by new vibro-impact system with

variable structure. System includes:adhered block 1; - main mass 2; - spring

with damper 3; - moving foundation 4; excitation system by harmonic vibration

force (with variable amplitude and it brake

off); - supply system.

2

4

10

n

1

1

3

2.659718

5

0

0

2

4

6

8

t

n

10

10

Fig. 19. Velocity of main mass in time

domain.

3.005351

5

v

n

0

2.659718

5

1

0.5

0.536376

0

x

n

0.5

1

0.570817

Fig. 20. Motion of main mass in phase

plane

1

3

Fig. 17. System with variable structure. 1 adhered block; 2 - main mass; 3 - spring

with damper; 4 - moving foundation with excitation system

111

148.19584

5

P

n

v

140.34304

7

5. Hibbeler, R.C. Mechanics of Materials.

PEARSON, Prentice-Hall, Inc. Singapore

629733. 2004.

20

0

0

8. CORRESPONDING AUTHOR

20

0

0

0

5

t

n

Akinfiev Teodor, professor, Dr.habil.sc.ing.

IAI CSIC, Spain,

IAI Carretera de Campo Real km 0.200 ::

Arganda del Rey :: 28500 MADRID ::

Apartado 56 :: ESPAÑA :: Tlf. (34) 91 871 19

00 :: Fax: (34) 91 871 70 50, E-mail:

teodor@iai.csic.es

1

01

0

Fig. 21. Harmonic vibration force (with

variable amplitude and brake)

6. CONCLUSION

Various new models of cutting zone

(mechanical hysteresis) are examined by

following elements: Hooke’s law, plastic

zone, failure point; - different stiffness

zones; - constant resistance zones; nonlinear (cubic and dry friction)

resistance forces; - linear and nonlinear

(cubic) processing media elastic forces and

variable system structure.

From analysis of motion character follows

that for adaptive systems trajectories in the

phase plane do not cross, and transient

process is very short. For modeling

systems with random parameters the

equation of motion is the same with

difference that some parameters are changing in time or randomly. Mechanical

problems of some systems with variable

structure are discussed.

7. REFERENCES

1. Lavendelis, E. Synthesis of optimal

vibro machines. Zinatne, Riga, 1970. (in

Russian).

2. Viba, J. Optimization and synthesis of

vibro impact systems. Zinatne, Riga, 1988.

(in Russian).

3. From Wikipedia, the free encyclopedia.

http://en.wikipedia.org/wiki/Reinforced_co

ncrete.

4. www.tmb-elements.lv.

112