Chapter 15 Exercise Solutions

advertisement

Chapter 15 Exercise Solutions

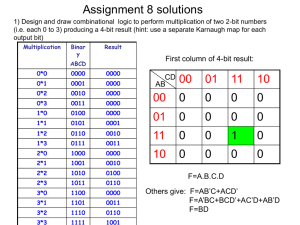

15-1.

LSL = 0.70 g/cm3, p1 = 0.02; 1 – = 1 – 0.10 = 0.90; p2 = 0.10; = 0.05

(a)

From the variables nomograph, the sampling plan is n = 35; k = 1.7.

Calculate x and S.

Accept the lot if Z LSL x LSL S 1.7 .

(b)

x 0.73; S 1.05 102

Z LSL 0.73 0.70 1.05 102 2.8571 1.7

Accept the lot.

(c)

Excel workbook Chap15.xls : worksheet Ex15-1

From the variables nomograph at n = 35 and k = 1.7:

p2

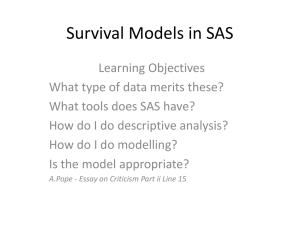

OC Curve for n=25, k=1.7

1.000

0.800

0.600

Pr{accept}

p1

p

Pr{accept}

0.010

0.988

0.016

0.945

0.020

0.900 1-alpha

0.025

0.820

0.030

0.730

0.040

0.560

0.050

0.400

0.070

0.190

0.100

0.050 beta

0.150

0.005

0.190

0.001

0.400

0.200

0.000

0.000

0.020

0.040

0.060

0.080

0.100

0.120

0.140

0.160

0.180

0.200

p

Pa{p = 0.05} 0.38 (from nomograph)

15-1

Chapter 15 Exercise Solution

15-2.

LSL 150; 5

p1 0.005;1 1 0.05 0.95; p2 0.02; 0.10

From variables nomograph, n = 120 and k = 2.3.

Calculate x and S.

Accept the lot if Z LSL x 150 S 2.3

15-3.

The equations do not change: AOQ = Pa p (N – n) / N and ATI = n + (1 – Pa) (N – n).

The design of a variables plan in rectifying inspection is somewhat different from the

attribute plan design, and generally involves some trial-and-error search.

For example, for a given AOQL = Pa pm (N – n) / N (where pm is the value of p that

maximizes AOQ), we know n and k are related, because both Pa and pm are functions of n

and k. Suppose n is arbitrarily specified. Then a k can be found to satisfy the AOQL

equation. No convenient mathematical method exists to do this, and special Romig tables

are usually employed. Now, for a specified process average, n and k will define Pa.

Finally, ATI is found from the above equation. Repeat until the n and k that minimize

ATI are found.

15-4.

AQL = 1.5%, N = 7000, standard deviation unknown

Assume single specification limit - Form 1, Inspection level IV

From Table 15-1 (A-2):

Sample size code letter = M

From Table 15-2 (B-1):

n = 50, knormal = 1.80, ktightened = 1.93

A reduced sampling (nreduced = 20, kreduced = 1.51) can be obtained from the full set of

tables in MIL-STD-414 using Table B-3. The table required to do this is available on the

Montgomery SQC website: www.wiley.com/college/montgomery

15-5.

Under MIL STD 105E, Inspection level II, Sample size code letter = L:

n

Ac

Re

Normal

200

7

8

Tightened

200

5

6

Reduced

80

3

6

The MIL STD 414 sample sizes are considerably smaller than those for MIL STD 105E.

Chapter 15 Exercise Solution

15-6.

N = 500, inspection level II, AQL = 4%

Sample size code letter = E

Assume single specification limit

Normal sampling: n = 7, k = 1.15

Tightened sampling: n = 7, k = 1.33

15-7.

LSL = 225psi, AQL = 1%, N = 100,000

Assume inspection level IV, sample size code letter = O

Normal sampling: n = 100, k = 2.00

Tightened sampling: n = 100, k = 2.14

Assume normal sampling is in effect.

x 255; S 10

Z LSL x LSL S 255 225 10 3.000 2.00, so accept the lot.

15-8.

= 0.005 g/cm3

x1 0.15;1 1 0.95 0.05

x A x1

(1 )

n

x A 0.15

1.645

0.005 n

x2 0.145; 0.10

x A x2

( )

n

x A 0.145

1.282

0.005 n

n 9 and the target x A = 0.1527

Chapter 15 Exercise Solution

15-9.

target = 3ppm; = 0.10ppm; p1 = 1% = 0.01; p2 = 8% = 0.08

(a)

1 – = 0.95; = 1 – 0.90 = 0.10

From the nomograph, the sampling plan is n = 30 and k = 1.8.

(b)

Note: The tables from MIL-STD-414 required to complete this part of the exercise are

available on the Montgomery SQC website: www.wiley.com/college/montgomery

AQL = 1%; N = 5000; unknown

Double specification limit, assume inspection level IV

From Table A-2:

sample size code letter = M

From Table A-3:

Normal: n = 50, M = 1.00 (k = 1.93)

Tightened: n = 50, M = 1.71 (k = 2.08)

Reduced: n = 20, M = 4.09 (k = 1.69)

known allows smaller sample sizes than unknown.

(c)

1 – = 0.95; = 0.10; p1 = 0.01; p2 = 0.08

From nomograph (for attributes): n = 60, c = 2

The sample size is slightly larger than required for the variables plan (a). Variables

sampling would be more efficient if were known.

(d)

AQL = 1%; N = 5,000

Assume inspection level II: sample size code letter = L

Normal: n = 200, Ac = 5, Re = 6

Tightened: n = 200, Ac = 3, Re = 4

Reduced: n = 80, Ac = 2, Re = 5

The sample sizes required are much larger than for the other plans.

Chapter 15 Exercise Solution

15-10.

Excel workbook Chap15.xls : worksheet Ex15-10

OC Curves for Various Plans with n=25, c=0

1.20

1.00

Pa

0.80

0.60

0.40

0.20

0.00

0

0.02

0.04

0.06

0.08

0.1

0.12

0.14

0.16

0.18

0.2

p

single

I=1

I=2

I=5

I=7

Compared to single sampling with c = 0, chain sampling plans with c = 0 have slightly

less steep OC curves.

Chapter 15 Exercise Solution

15-11.

N = 30,000; average process fallout = 0.10% = 0.001, n = 32, c = 0

Excel workbook Chap15.xls : worksheet Ex15-11

(a)

p

0.0010

0.0020

0.0030

0.0040

0.0050

0.0060

0.0070

0.0080

0.0090

0.0100

0.0200

0.0300

0.0400

0.0500

0.0600

0.0700

0.0800

0.0900

0.1000

0.2000

0.3000

Pa

Pr{reject}

0.9685

0.0315

0.9379

0.0621

0.9083

0.0917

0.8796

0.1204

0.8518

0.1482

0.8248

0.1752

0.7987

0.2013

0.7733

0.2267

0.7488

0.2512

0.7250

0.2750

0.5239

0.4761

0.3773

0.6227

0.2708

0.7292

0.1937

0.8063

0.1381

0.8619

0.0981

0.9019

0.0694

0.9306

0.0489

0.9511

0.0343

0.9657

0.0008

0.9992

0.0000

1.0000

OC Chart for n=32, c=0

1.0

Probability of Acceptance, Pa

0.8

0.6

0.4

0.2

0.0

0.00

0.02

0.04

0.06

0.08

0.10

0.12

Fraction Defective, p

0.14

0.16

0.18

0.20

Chapter 15 Exercise Solution

15-11 continued

(b)

ATI n (1 Pa )( N n)

32 (1 0.9685)(30000 32)

976

(c)

Chain-sampling: n = 32, c = 0, i = 3, p = 0.001

Pa P(0, n) P(1, n)[ P(0, n)]i

P(0, n) P(0,32) 0.9685

P(1, n) P(1,32) 0.0310

Pa 0.9685 (0.0310)(0.9685)3 0.9967

ATI 32 (1 0.9967)(30000 32) 131

Compared to conventional sampling, the Pa for chain sampling is slightly larger, but the

average number inspected is much smaller.

(d)

Pa = 0.9958, there is little change in performance by increasing i.

ATI 32 (1 0.9958)(30000 32) 158

Chapter 15 Exercise Solution

15-12.

n = 4, c = 0, i = 3

Excel workbook Chap15.xls : worksheet Ex15-1

p

0.0010

0.0100

0.0200

0.0300

0.0500

0.0600

0.0700

0.0800

0.0900

0.1000

0.2000

0.3000

0.4000

0.5000

0.6000

0.7000

0.8000

0.9000

0.9500

P(0,4)

0.9960

0.9606

0.9224

0.8853

0.8145

0.7807

0.7481

0.7164

0.6857

0.6561

0.4096

0.2401

0.1296

0.0625

0.0256

0.0081

0.0016

0.0001

0.0000

P(1,4)

0.0040

0.0388

0.0753

0.1095

0.1715

0.1993

0.2252

0.2492

0.2713

0.2916

0.4096

0.4116

0.3456

0.2500

0.1536

0.0756

0.0256

0.0036

0.0005

Pa

0.9999

0.9950

0.9815

0.9613

0.9072

0.8756

0.8423

0.8080

0.7732

0.7385

0.4377

0.2458

0.1304

0.0626

0.0256

0.0081

0.0016

0.0001

0.0000

OC Curve for ChSP-1 n=4,c=0

1.00

0.90

0.80

0.70

Pa

0.60

0.50

0.40

0.30

0.20

0.10

0.00

0.00

0.10

0.20

0.30

0.40

0.50

p

0.60

0.70

0.80

0.90

1.00

Chapter 15 Exercise Solution

15-13.

N = 500, n = 6

If c = 0, accept. If c = 1, accept if i = 4. Need to find Pa{p = 0.02}

Pa P(0, 6) P(1, 6)[ P(0, 6)]4 0.88584 0.10847(0.88584) 4 0.95264

15-14.

Three different CSP-1 plans with AOQL = 0.198% would be:

1.

f = ½ and i = 140

2.

f = 1/10 and i = 550

3.

f = 1/100 and i = 1302

15-15.

Average process fallout, p = 0.15% = 0.0015 and q = 1 – p = 0.9985

1.

f = ½ and i = 140: u = 155.915, v = 1333.3, AFI = 0.5523, Pa = 0.8953

2.

f = 1/10 and i = 550: u = 855.530, v = 6666.7, AFI = 0.2024, Pa = 0.8863

3.

f = 1/100 and i = 1302: u = 4040.000, v = 66,666.7, AFI = 0.0666, Pa = 0.9429

p

0.0010

0.0015

0.0020

0.0025

0.0030

0.0035

0.0040

0.0045

0.0050

0.0060

0.0070

0.0080

0.0090

0.0100

0.0150

0.0200

0.0250

0.0300

0.0350

0.0400

0.0450

0.0500

0.0600

0.0700

0.0800

0.0900

0.1000

f = 1/2 and i = 140

u

v

Pa

1.5035E+02 2000.0000 0.9301

1.5592E+02 1333.3333 0.8953

1.6175E+02 1000.0000 0.8608

1.6788E+02 800.0000 0.8266

1.7431E+02 666.6667 0.7927

1.8106E+02 571.4286 0.7594

1.8816E+02 500.0000 0.7266

1.9562E+02 444.4444 0.6944

2.0346E+02 400.0000 0.6628

2.2037E+02 333.3333 0.6020

2.3909E+02 285.7143 0.5444

2.5984E+02 250.0000 0.4904

2.8284E+02 222.2222 0.4400

3.0839E+02 200.0000 0.3934

4.8648E+02 133.3333 0.2151

7.9590E+02 100.0000 0.1116

1.3449E+03

80.0000 0.0561

2.3371E+03

66.6667 0.0277

4.1604E+03

57.1429 0.0135

7.5602E+03

50.0000 0.0066

1.3984E+04

44.4444 0.0032

2.6266E+04

40.0000 0.0015

9.6355E+04

33.3333 0.0003

3.6921E+05

28.5714 0.0001

1.4676E+06

25.0000 0.0000

6.0251E+06

22.2222 0.0000

2.5471E+07

20.0000 0.0000

f = 1/10 and i = 550

u

v

Pa

7.3373E+02 10000.0000 0.9316

8.5553E+02 6666.6667 0.8863

1.0037E+03 5000.0000 0.8328

1.1848E+03 4000.0000 0.7715

1.4066E+03 3333.3333 0.7032

1.6795E+03 2857.1429 0.6298

2.0162E+03 2500.0000 0.5536

2.4329E+03 2222.2222 0.4774

2.9502E+03 2000.0000 0.4040

4.3972E+03 1666.6667 0.2749

6.6619E+03 1428.5714 0.1766

1.0238E+04 1250.0000 0.1088

1.5930E+04 1111.1111 0.0652

2.5056E+04 1000.0000 0.0384

2.7157E+05

666.6667 0.0024

3.3467E+06

500.0000 0.0001

4.4619E+07

400.0000 0.0000

6.2867E+08

333.3333 0.0000

9.2451E+09

285.7143 0.0000

1.4085E+11

250.0000 0.0000

2.2128E+12

222.2222 0.0000

3.5731E+13

200.0000 0.0000

1.0035E+16

166.6667 0.0000

3.0852E+18

142.8571 0.0000

1.0318E+21

125.0000 0.0000

3.7410E+23

111.1111 0.0000

1.4676E+26

100.0000 0.0000

f = 1/100 and i = 1302

u

v

Pa

2.6790E+03 100000.0000 0.9739

4.0401E+03 66666.6667 0.9429

6.2765E+03 50000.0000 0.8885

1.0010E+04 40000.0000 0.7998

1.6331E+04 33333.3333 0.6712

2.7161E+04 28571.4286 0.5127

4.5912E+04 25000.0000 0.3526

7.8675E+04 22222.2222 0.2202

1.3638E+05 20000.0000 0.1279

4.2131E+05 16666.6667 0.0381

1.3395E+06 14285.7143 0.0106

4.3521E+06 12500.0000 0.0029

1.4383E+07 11111.1111 0.0008

4.8192E+07 10000.0000 0.0002

2.3439E+10

6666.6667 0.0000

1.3262E+13

5000.0000 0.0000

8.2804E+15

4000.0000 0.0000

5.5729E+18

3333.3333 0.0000

3.9936E+21

2857.1429 0.0000

3.0255E+24

2500.0000 0.0000

2.4121E+27

2222.2222 0.0000

2.0179E+30

2000.0000 0.0000

1.6195E+36

1666.6667 0.0000

1.5492E+42

1428.5714 0.0000

1.7586E+48

1250.0000 0.0000

2.3652E+54

1111.1111 0.0000

3.7692E+60

1000.0000 0.0000

Chapter 15 Exercise Solution

15-16.

CSP-1 with AOQL = 1.90%

Plan A: f = 1/5 and i = 38

Plan B: f = 1/25 and i = 86

15-17.

Plan A: AFI = 0.5165 and Pa{p = 0.0375} = 0.6043

Plan B: AFI = 0.5272 and Pa{p = 0.0375} = 0.4925

Prefer Plan B over Plan A since it has a lower Pa at the unacceptable level of p.