Lab Safety Lecture

advertisement

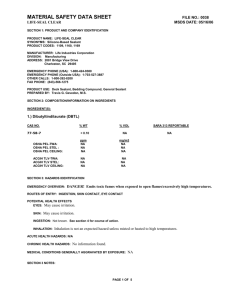

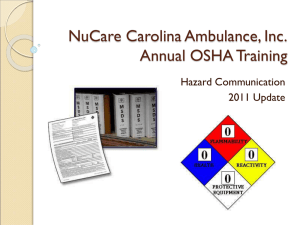

Lab Safety Lecture ChE 432-Section 1 & 2 Su Ha & Van Wie Outlines •Permission to Start Experiments •Why is Safety important? •Federal Laws •Material Safety Data Sheets (MSDS) •Laboratory Safety Equipment •Chemical Spill Management •Methods of Process Hazards Analysis Permission to Start Experiments Due this Friday (9/3) at 5PM Submit the following items to lab instructor for approval: 1. list of credible hazards associated with your experiment 2. consequences of hazards 3. mitigation of hazards 4. process flow diagram (Some groups need to redo it) 5. experiment startup procedure 6. operating procedure 7. shutdown procedure 8. emergency shutdown procedure 9. MSDS sheets of any chemicals used 10.plan for waste disposal 11.Experimental plans 12.Safety Checklist Why is Safety important? • Legal Requirement and Federal Law • Financial Implications • Own Desire to Work in Safe Environments • Moral Responsibility Not To Endanger Other People Federal Laws Occupational Safety and Health Administration (OSHA) Bloodborne Pathogens. Concerns about workplace exposures to blood-borne pathogens led the Occupational Safety and Health Administration (OSHA) to issue regulation 29CFR 1910.1030 in 1991. Employers are required to prepare a plan to control blood-borne pathogen exposure, including the adoption of universal precautions to prevent exposure to blood-borne pathogens such as HIV and Hepatitis B. This statute applies not only to blood but to other body fluids. Hazard Communication Standard (Right to Know). In 1983 the Federal Hazard Communication Standard (29CFR 1910.1200) became law. Basically, this law requires employers whose employees use toxic substances to provide these employees with (1) material safety data sheets (MSDS) that describe the properties, safe handling, and health hazards of the toxic materials; (2) labeling of all toxic substances with product name and a hazard warning; and (3) annual training on the hazards of toxic substances, safe handling procedures, and how to read MSDS. Federal Laws (Continued) Environmental Protection Agency (EPA). The Environmental Protection Agency regulates the disposal of hazardous wastes, including wastes from academic laboratories. The following websites offer more information on this topic: http://www.access.gpo.gov/nara/cfr/index.html - Source for Code of Federal Regulations (CFR) http://www.epa.gov - Environmental Protection Agency What are Hazardous Chemicals? Hazardous chemicals are any products or materials that present any physical or health hazards when used, unless they are exempted under the law. In ETRL 4, any chemicals (including a tape water) should be considered as a hazardous chemical and you must wear gloves, eye goggles and helmets at all times. Material Safety Data Sheets (MSDS) A Material Data Safety Sheet, prepared by the chemical manufacturer in accordance with OSHA's Haz-Com Standard, indicates the hazard and safe handling information for a chemical. http://www.ehs.wsu.edu/ohs/ohs-MSDS.html MSDS Contents 1. Identification of substance 2. Composition/Data on components 3. Hazards identification 4. First aid measures 5. Fire fighting measures 6. Spill cleanup measures 7. Handling and storage 8. Exposure controls and personal protection 9. Physical and chemical properties 10. Stability and reactivity 11. Toxicological information 12. Ecological information 13. Disposal considerations 14. Transport information 15. Regulations 16. Other information Hazardous Materials Identification System (Fire Diamond) The National Fire Protection Agency (NFPA) In section 704 of the National Fire Code, specifies a system for identifying the hazards associated with materials Hazardous Materials Identification System (Fire Diamond) Hazardous Materials Identification System (Fire Diamond) Hazardous Materials Identification System (Color Bar) Laboratory Safety Equipment 1. Laboratory Safety Manual (http://www.ehs.wsu.edu/LSM/wsulsmhome.asp) 2. safety shower (1) 3. eye wash station (3) 4. fire extinguisher in lab and closest extinguisher in hall 5. Fire Blanket 6. fire alarm in lab and closest alarm in hallway 7. first-aid kit 8. telephone and emergency number 9. lab safety manual 10.chemical spill kit (understand the contents) 11.Telephone Chemical Spill Management Each WSU laboratory must decide how it will manage hazardous chemical spills. The laboratory (1) may opt to clean up its own spills, (2) may initiate the university's emergency response system by calling 911 and reporting a chemical spill, or may (3) institute a combination of the two. • For ChE 432 Class, you directly report any chemical spills to your lab instructors!! • Do Not Clean them yourself unless your lab instructors give you the permission to do so!! If one breaks a mercury thermometer during normal business hours call 335-3041 for assistance. Methods of Process Hazards Analysis On July 17, 1990, OSHA issued a proposed rule for the management of hazards associated with processes using highly hazardous chemicals. This rule, called the Process Safety Management standard, was finalized on February 24, 1992. In an appendix to the proposed rule, OSHA discussed several methods of process hazard analysis. That discussion, which may be helpful for those doing job hazard analyses, follows: 1. 2. 3. 4. 5. 6. What-if Checklist What-if/Checklist Hazard and Operability Study (HAZOP) Failure Mode and Effect Analysis (FMEA) Fault Tree Analysis Please Read a Handout of OSHA methods of PHA !!! Choice of method depends on complexity of process Methods of Process Hazards Analysis What-if. For relatively uncomplicated processes, review the process from raw materials to product. At each handling or processing step, "what if" questions are formulated and answered, to evaluate the effects of component failures or procedural errors on the process. Guide Words NONE MORE OF LESS OF PART OF MORE THAN OTHER THAN Example Deviations no flow higher flow, pressure etc.. less flow, pressure etc.. wrong composition more components, more phases etc.. Case Study First Chemical Corporation accident Type of Unit Operation: mono-nitrotoluene distillation column Accident Descriptions: column taken off line->entire facility shut down->plant boilers brought back->1200 gallons of MNT in column was heated to 450oF->column ruptured and exploded Damages: 3 workers injured, a 13,500 lb chunk of the column was blown 1,100 ft away (landed across street in Chevron refinery), the 7 ft diameter head of the column was never found, all the structured packing was blown out & started burning Root Causes of Accident •failure to understand thermal decomposition of MNT •no formal hazard analysis •column not equipped with sufficient layers of protection •no effective system for ensuring consistent work practices when isolating equipment •MSDS didn’t give proper caution about MNT So not only design important but also maintenance and operating procedures!!