CH250 Lecture notes

advertisement

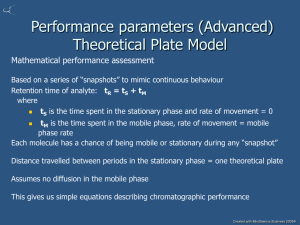

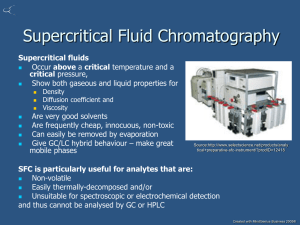

CH250 Interactive Notes Created with MindGenius Business 2005® Created with MindGenius Business 2005® CH250 Intermediate Analysis 1. Review of CH115/CH108 material (ELO) 2. Analytical Design (ELO) method selection validation 3. Sampling (ELO) 4. Sample preparation (ELO) 5. Detection and identification Spectroscopy (AW) Electrochemistry (AW) Spectrometry (Mass Spectrometry and NMR, ELO) Materials and Nanotechnology (RW) Created with MindGenius Business 2005® 1. Review of CH115/CH108 The analytical process – designing analyses Errors and uncertainty Sample collection, preparation and storage Calibration methods, spiking and recovery, LOD, LOQ Classical Analyses: Gravimetry and Titrimetry Instrumental Analyses: Chromatography (HPLC, GC, TLC) Spectroscopy (UV, AAS) Electrochemistry (ISE) Created with MindGenius Business 2005® The analytical process Analysis must be: “Fit for purpose” i.e. Representative, selective and reliable Process Formulating the question (Aims) Selecting an analytical technique (Introduction) Conducting the analysis (Methods) Reporting the data (Results) Answering the question (Discussion/Conclusion) Created with MindGenius Business 2005® Errors and Uncertainty Accuracy vs precision, significant figures Types, Sources and methods of avoiding uncertainty, Measures of location and spread Gaussian distribution & student’s t, populations and samples, degrees of freedom Comparison of Means: Student’s t-test (3 variants) Comparison of precision/s : f-test Investigation of Outliers: Dixon’s Q and Grubbs Propagation of errors Reproducibility, repeatability, interlaboratory trials Created with MindGenius Business 2005® Sample collection, preparation and storage Sampling Ensuring selective, reliable and representative sampling Factors influencing choice of method Homogeneous vs heterogeneous samples Storage Understand and discuss methods for avoiding Contamination Decomposition Preparation Choose and describe simple methods of preparation for given examples Created with MindGenius Business 2005® Calibration External Standard, Standard Addition, Internal Standards Spiking and recovery Draw appropriate graphs and calculate the concentration of an unknown from them Calculation errors in linear regression, and thus in the unknown LOD, LOQ Convert measured concentration into amount in original sample, with uncertainty. Created with MindGenius Business 2005® Classical Analyses: Gravimetry and Titrimetry Correct methods of weighing and measuring Unit conversion calculations, yields Sample preparation and dilution Types of analysis Created with MindGenius Business 2005® Instrumental analyses Chromatography Spectroscopy Physicochemical principles of separation Formats: plate vs gel Types: HPLC, GC,TLC Parameters, quantitation (peak shape, size, resolution) UV – Beer-Lambert, Practical applications AAS – simple inorganic analysis Electrochemistry –ISEs, Nernst equation Created with MindGenius Business 2005® CH250 Intermediate Analysis 1. Review of CH115/CH108 material (ELO) 2. Analytical Design (ELO) method selection validation 3. Sampling (ELO) 4. Sample preparation (ELO) 5. Detection and identification Spectroscopy (AW) Electrochemistry (AW) Spectrometry (Mass Spectrometry and NMR, ELO) Materials and Nanotechnology (RW) Created with MindGenius Business 2005® 2. Analytical Design Method selection Validation Background Reading: Quality Assurance in Analytical Chemistry, Chapter 4 VAM leaflet: Introduction to method validation (on Studentcentral) Created with MindGenius Business 2005® Method selection vs Validation Define analytical requirements Select/Develop candidate method NO Validation document YES Criteri a met? Plan validation experiments Conduct validation experiments Assess fitness for purpose Based on: Quality Assurance in Analytical Chemistry, Chapter 4, Fig. 4.2 Created with MindGenius Business 2005® Principles of method selection (1) Components Practicalities Accuracy Created with MindGenius Business 2005® Principles of Method Selection (2) What are the analytes? What else is present (matrix)? Components Will it interfere – false positive or negative? Over repeated runs? How accurate do the results have to be? What properties do they have? How much is present? How big/small an effect am I looking for? What are the minimum amounts that must be detected? Which must be eliminated – false positives or negatives? What are the consequences of incorrect results? How many samples must be analysed? What resources are available? Accuracy Resources Created with MindGenius Business 2005® Components: Analyte and Matrix The physico-chemical properties of components affect: Separation methods: depends on all components (exploiting differences between analyte and matrix) Detection method: must use analyte property Level of selectivity needed: depends on scale and type of differences between analyte and matrix Created with MindGenius Business 2005® Accuracy Successful analysis means setting, testing and meeting performance criteria Qualititative or quantitative Depend on the acceptable level of uncertainty (risk) Criteria allow objective selection of sampling, separation and detection methods Common criteria include measures of: Precision Selectivity/specificity Bias Ruggedness Linearity (working range) Limit of Detection / Quantitation Created with MindGenius Business 2005® Resources Cost, availability of instruments, materials and staff will affect: Number of samples Available methods Accuracy of measurements Rate of turnaround Must be balanced against the consequences of an incorrect result Created with MindGenius Business 2005® Finding a suitable method Sources of potential methods include: Primary scientific literature Patents British & international standards (via UoB online library) Manufacturer’s technical information You may find several potential methods, but: It is rare to find one which is perfect Objective criteria are needed to select the best method Adapted methods must then be validated to make sure they are… Created with MindGenius Business 2005® FIT-FOR-PURPOSE Created with MindGenius Business 2005® Thought Exercise –In groups 1) Write down five chemical properties a) Name a separation technique that exploits differences in each of these b)Name a detection method for each c) Add an example of matrix and analyte for each of the five 2) Give an example of an analysis where each of the following might occur: a) High risk (minimal consequence) false positive result b)Low risk, false positive result c) High risk, false negative result d)Low risk, false negative result Created with MindGenius Business 2005® Validation “Confirmation by the examination and the provision of objective evidence, that the particular requirements for a specific intended use are fulfilled.” Reference: ISO/IEC 17025:2005. General requirements for the competence of testing and calibration laboratories Created with MindGenius Business 2005® How to validate? Purpose Performance Criteria Test Plan Interpretation What exactly are we analysing for? Assay, iD, limit (impurities) What are limits to the conditions the analysis covers? What objective parameters will show whether the goals have been met? Will these detect failures? How best can the parameters be measured? How should the data be compared to the specified parameters ?(statistics?, blind trials?) Created with MindGenius Business 2005® Performance criteria Type of Analysis Parameter Qualitative Major (Identification) Component Precision Specificity/Selectivity Bias Ruggedness Linearity/working range Limit of Detection Limit of Quantitation Trace Analysis Physical Properties Created with MindGenius Business 2005® Precision Definition: “The closeness of agreement between independent test results obtained under specified conditions”. Includes reproducibility and repeatability. Affected by: Number of measurements, uncontrolled random errors. Measurement: Measures of spread (s, 95% CI etc.) Should include effect of factors that will not be consistent during normal use of method. Evaluation: Acceptable levels of precision depend on the levels of variability tolerated. Effect of concentration may be large. Bias also affects precision requirements. Student’s t and f tests. Are you hitting the bullseye? Created with MindGenius Business 2005® Specificity Definition: “The extent to which a method can be used to determine particular analytes in mixtures or matrices without interference from the presence of components with similar behaviour.” Affected by: Types of components routinely present. Lack of specificity can give a false negative or positive. Measurement: Increasing concentrations of potential interferents added to samples. Can quantify at what concentrations interference becomes significant. Spot the Oak leaf? Evaluation: Most important in trace analysis as contaminants can be significant. False positives can be neglected in screening assays, if followed by second confirmatory technique. Created with MindGenius Business 2005® Bias Definition: “The difference between the calculated value and the accepted reference standard”. A Measure of trueness Affected by: Systematic errors. Measurement: Spiking and recovery (how much of a known amount of analyte added at to the starting sample is measured by the analysis). Measurement with alternative validated method. Interlaboratory trials – to establish causes of bias. Evaluation: Simple t-test (compare result to known value). Bias and precision combine to give accuracy Altered gravity – or systematic building error? Created with MindGenius Business 2005® Ruggedness Definition: The degree to which a method is affect by small changes in the operating conditions. Associated with both precision and bias. Affected by: type of technique, number of variable parameters Measurement: Deliberately vary conditions to quantify their effect on results, and identify critical parameters. Evaluation: Focused on identifying prime causes of variability, and setting controls for these. Don’t get stuck in the mud? Created with MindGenius Business 2005® Linearity Definition: “The ability to produce test results that are proportional to the analyte concentration within a given range.” Measurement: Calibration, ideally with CRMs or spiked samples. Concentrations must be evenly spaced. LOQ is often lower limit. Evaluation: May use visual inspection, r, runs test. 20 18 16 Measured Vaule Affected by: Technique, interferents, recovery. Working range 14 12 10 8 6 4 2 0 0 5 10 15 20 25 30 Concentration LOD LOQ Created with MindGenius Business 2005® Limit of Detection (LOD) Definition: “The minimum concentration of analyte that can be detected with statistical confidence.” Affected by: method, uncertainty…the kitchen sink Measurement: Concentration (calculated from line of best fit) at which either (a) signal is equivalent to blank + 3 x sd of blank or (b) intercept (y0) + (3 x Sxy) Evaluation: No analysis should rely on a value below this. All but qualitative analyses should use the higher LOQ. Is this glass empty, or not? Created with MindGenius Business 2005® Limit of Quantitation Definition: “The lowest concentration of analyte that can be determined with an acceptable level of uncertainty.” Affected by: Method performance…no really! Measurement: As for LOD but 10 x sd of blank Evaluation: This is the point at which quantitative analysis can be considered valid. May require multiple assays (alongside reproducibility studies to set limits appropriately). The world’s smallest ruler? 1 Division = 1.25µm Created with MindGenius Business 2005® Thought exercise 2 You are to validate a new method for the analysis of calcium in infant formula: 1) What are the key features of this analysis? 2) What interferents might be important? 3) How would you decide what limits should be set for each of these parameters? a) Precision b) Selectivity/specificity c) Bias d) Ruggedness e) Linearity (working range) f) Limit of Detection / Quantitation 4) How would you determine if your analysis met the criteria specified? Created with MindGenius Business 2005® Validation Documentation and QC Key Features include: Description of method, including scope (what can it do, and what can it not do?) All important technical details (how do I do it?) Expected performance criteria (how well does it do it?) Warning limits – normally 2-3 times within lab precision (how can you tell if it is not working?) Responsible signatory, dated versions and revisions, document control to ensure currency See also end of Chapter 4: Quality Assurance in Analytical Chemistry Created with MindGenius Business 2005® Typical Documentation 1. Scope and applicability • • • 2. Samples Analytes Ranges Description and principle of the method Equipment 3. • • • 4. Specification Calibration and qualification Range of operability Reference materials and reagents • • • 5. 6. Specification Preparation Storage Health & Safety Sampling • • • Methods Storage Limitations 7. Analytical Procedure • • • • • Preparation of samples Preparation of standards Critical factors Detailed description of all steps Typical outputs; chromatograms, spectra, etc. 8. Recording and reporting of data • • • Method Rounding and significant figures Data treatments 9. Calculation of results • • • Calibration model Calculation methods Assumptions and limitations 10.Method performance • • Statistical measures Control charting 11.References & Bibliography Created with MindGenius Business 2005® Validation proposal activity 1 Make a Word (or equivalent) template covering each of the items from the suggested table of contents for a validation document on the previous slide Add your ideas from the thought exercise about calcium in infant formula Decide which areas require further research and which may be answered during the practical sessions Use the scientific literature to research possible answers to questions Make notes on how you might decide which of two methods is more suitable – can you prioritise performance criteria? You will add to this document during the course of the module – it is designed to form the basis of your final assessment – the “validation proposal”. Created with MindGenius Business 2005® CH250 Intermediate Analysis 1. Review of CH115/CH108 material (ELO) 2. Analytical Design (ELO) method selection validation 3. Sampling (ELO) 4. Sample preparation (ELO) 5. Detection and identification Spectroscopy (AW) Electrochemistry (AW) Spectrometry (Mass Spectrometry and NMR, ELO) Materials and Nanotechnology (RW) Created with MindGenius Business 2005® 3. Sampling (ELO) “A defined procedure whereby a part of a substance, material or product is taken to provide for testing or calibration a representative sample of the whole. Sampling may also be required by the appropriate specification for which the substance, material or product is to be tested or calibrated.” ie The sample(s) must be REFLECTIVE of the TRUE situation Background Reading: Quality Assurance in Analytical Chemistry, Chapter 3 For an example relevant to your analyses, see BS EN ISO 707:2008 Milk and milk products – Guidance on sampling Created with MindGenius Business 2005® Sampling Strategies (1) Depend on: Types of parent material Concentration Trace (prone to heterogeneity and contamination) Principal component (% uncertainty much lower) Packaging Homogeneous or heterogeneous Static (stable and contained) or dynamic (cannot be resampled) Bulk (eg a silo) Packaged (eg cornflakes) Items (eg tablets) Results required Quantitative (how much) Qualitative or compliance (yes/no answer) – “acceptance sampling” Created with MindGenius Business 2005® Sampling Strategies (2) Criteria? attributes (x% of items must conform) variables (a specified average and sd) Selective sampling OK? (eg fruit but not stone)? Overall strategy determined by purpose: Client requirements Statutory requirements (legal obligations) Trade definitions (contractual) Created with MindGenius Business 2005® Types of Sampling 100% sampling (all items monitored) Probability sampling (statistical chance of being representative) Judgement (guided by the reason for analysis) Quota (stratified judgement sampling) Convenience (as and when available) Non-probability sampling (selective) Created with MindGenius Business 2005® Sample size and number Must be specified as part of the method. Sample Size Enough for method Enough to be reflective (esp for trace analysis) Sample number enough to reduce uncertainty (esp that from sampling) to acceptable levels Created with MindGenius Business 2005® Sampling Uncertainty Overall uncertainty in analysis is composed of: Measurement uncertainty (quantifiable using standards) Sample uncertainty which is caused by Population uncertainty (real wobble in the system) Sampling uncertainty (due to the process of collection) Sampling uncertainty must be reduced until: it does not obscure population uncertainty the resource required outweighs the risk of an incorrect result More samples and smaller particles reduce sampling uncertainty See also CH250:1 Causes of uncertainty Created with MindGenius Business 2005® How many samples are needed? Number of samples needed can be estimated by rearranging the equation for confidence intervals: ConfidenceInterval ts n ts n E 2 n is the number of samples t is Student’s t (routinely approximated to 2 for 95% confidence) s is the standard deviation for the method (measured using reference standards, and inter-laboratory trials) E is the size of the effect that must be measurable (in the same units as s). Created with MindGenius Business 2005® Number of samples - worked eg Cadmium concentrations in soil were measured at a brownfield site during preliminary surveying. The mean ± standard deviation were (16 ± 4) ppm. a) Calculate the number of samples required to obtain a total uncertainty of 20%. b) How many samples would be required to reduce this uncertainty to 10%? Created with MindGenius Business 2005® Number of samples - Answer Cadmium concentrations in soil were measured at a brownfield site during preliminary surveying. The mean ± standard deviation were (16 ± 4) ppm. a) E 24 3 .2 6.25 n a) Calculate the number of samples required to obtain a total uncertainty of 20%. Between 6 and 7, assuming t=2 b) b) How many samples would be required to reduce this uncertainty to 10%? 25, assuming t=2 n 20% of 0.2 16 3.2 ppm E 2 10% of 0.1 16 1.6 ppm 24 1 .6 25 16 16 2 Created with MindGenius Business 2005® How big should the sample be? There are various statistical calculations based on a) the proportion of analyte present and b) the particle size to approximate sample mass needed. The simplest of these is as follows: Ks %CV m 2 %CV 100 s x Where Ks is the sampling constant, m is the mass in g and %CV is the Coefficient of Variation (which must be calculated from measurements on several test portions). Created with MindGenius Business 2005® How big should the sample be? Once Ks is known the equation can be rearranged to calculate: a) The test portion mass (m) required to achieve a specified %CV m Ks (%CV ) 2 b) The likely %CV from a given test portion mass %CV Ks m Created with MindGenius Business 2005® CH250 Intermediate Analysis 1. Review of CH115/CH108 material (ELO) 2. Analytical Design (ELO) method selection validation 3. Sampling (ELO) 4. Sample preparation (ELO) 5. Detection and identification Spectroscopy (AW) Electrochemistry (AW) Spectrometry (Mass Spectrometry and NMR, ELO) Materials and Nanotechnology (RW) Created with MindGenius Business 2005® 4. Sample preparation (ELO) Dissolution and digestion Derivatisation Separation Strategies Extraction methods Chromatography Created with MindGenius Business 2005® Sample Preparation Need to get the bulk sample into the correct: form (solution, gas etc) concentration (high enough to detect, and low enough to be in linear range) purity (away from interferents) …without losing any analyte Created with MindGenius Business 2005® Separation vs Recovery Separation Recovery Created with MindGenius Business 2005® Dissolution and digestion Δ i.e. the process of turning messy, often complex gunge into a nice clean solution. Δ may involve: heat microwave radiation ultrasonic baths pressure acids and other solvents (chemical energy) The important feature is that it converts the analyte into an accessible form (sometimes purifying it as a result), without losing or destroying any of it. (See also extraction) Created with MindGenius Business 2005® Derivatisation Chemically converting the analyte into a form that renders it easier to separate or detect. It often involves: Selective chemical reactions Change in physical behaviour (eg boiling point or spectra) Requires careful optimisation and monitoring to ensure recovery (ie ~100% conversion) Created with MindGenius Business 2005® Extraction Dissolution Extraction Chromatography Purification based on relative affinity for extracting media May isolate analyte from solid, liquid or gaseous matrices Can involve extraction to solvent or solid phase media The following are readable reviews of this stage of sample preparation: 1. Roger M Smith. (2003) Before the injection – modern methods of sample preparation for separation techniques J. Chromatography A, 1000, 3-27. 2. Kathy Ridgway et. al.(2007) Sample Preparation techniques for the determination of trace residues and contaminants in food. J. Chromatography A, 1153, 36-53. Created with MindGenius Business 2005® Analytes in Solid Samples Particle size is important – so may need pre-extraction homogenisation Solvent is chosen to enhance selectivity May also require Recycling (Soxhlet) Heating (boiling, or superheating under pressure) Supercritical fluids Microwave and sonic radiation (difficult to automate) Aqueous pastes (eg meat or plant tissue) require special care – sometimes using powdered matrix Insoluble analytes may be pyrolysed (to produce soluble fragments) Volatile analytes may be “thermally desorped” and then treated as for gases Created with MindGenius Business 2005® Analytes in Solution Biphasic (aqueous/organic) liquid-liquid extraction but has problems Purge and Trap (volatile analyte flushed out by gas) Dialysis Costly in solvent Waste/environmental concerns increae cost Concentration of solvent gives loss of volatile analytes and concentration of solvent impurites Uses a membrane to separate layers / increase selectivity Solid phase extraction/microextraction Created with MindGenius Business 2005® Solid-Phase Extraction Adsorbent coated on packed powder fibre/capillary beads stirrer bar low waste automatable effective concentration May be “in-line” Performance is affected by flow rate preconditioning Brand matrix Most chromatographic phases available Advantages include C18 ion exchange size exclusion chiral, immunoaffinity and molecular imprinted Requires desorption post extraction by solvent thermally (GC injection port) Created with MindGenius Business 2005® Gaseous Analytes Problems Sample preparation focuses on trapping low concentration difficult to store cooling bubbling through solution adsorbing to fibre Need to control for misting and desolvation Created with MindGenius Business 2005®