Analytical Design(2)

advertisement

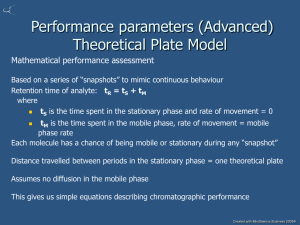

CH217 Fundamentals of Analytical Chemistry Module Leader: Dr. Alison Willows Created with MindGenius Business 2005® Created with MindGenius Business 2005® Assessment Practicals 60% Practical 1: online quiz during lab session Practicals 2 & 3: electronic reports, see lab scripts End of module examination 40% In addition you are also required to: Complete the guided study (not assessed) Attend all the labs Attend at least 80% lectures/workshops Created with MindGenius Business 2005® Studentcentral Module content and assignments are available through studentcentral You will be required to submit your coursework electronically via studentcentral The guided study will be an electronic test on studentcentral Feedback on assessments will also be electronic Please familiarise yourself with studentcentral! Created with MindGenius Business 2005® Recommended reading The module descriptor tells you what you should know by the end of this module The information given in lectures and on studentcentral is only a guideline to aid your study Please refer to the module learning handbook and studentcentral for a list of recommended books and other useful resources. You will not achieve a good grade in this module without doing additional reading outside of the lectures Created with MindGenius Business 2005® Principles of Analytical design DTI's Valid Analytical Measurement programme The six principles of good analytical practice Analytical measurements should be made to satisfy an agreed requirement. Analytical measurements should be made using methods and equipment which have been tested to ensure they are fit for purpose. Staff making analytical measurements should be both qualified and competent to undertake the task. There should be a regular independent assessment of the technical performance of a laboratory Analytical measurements made in one location should be consistent with those elsewhere. Organisations making analytical measurements should have well defined quality control and quality assurance procedures. Created with MindGenius Business 2005® Role of analytical chemistry in science Do I need analytical chemistry? Analytical chemistry might: enable you to pass your course help you to understand other modules be useful in your career be interesting help with your final year project change your life! Created with MindGenius Business 2005® What is analytical chemistry? Dictionary definitions Analytical (adj) examining or tending to examine things very carefully Chemistry(noun) 1.(the part of science which studies) the basic characteristics of substances and the different ways in which they react or combine with other substances. 2. INFORMAL understanding and attraction between two people Cambridge Advanced Learner's dictionary Analytical chemistry encompasses any type of test that provides information on the amount or identification of the chemical composition of a sample. This breaks down into two main areas of analysis: qualitative and quantitative Created with MindGenius Business 2005® Qualitative vs.. Quantitative Qualitative analyses give a positive/negative or yes/no answer. This tells us whether a substance (the analyte) is present but doesn't tell us how much is there. A qualitative analysis may also identify substances in a sample Quantitative analyses tell us how much of a substance is in the sample. Created with MindGenius Business 2005® When and where is analytical chemistry used? Food industry - wine production; contaminants; process lines Medical - blood analysis; imaging; Pharmaceutical - drug analysis Environmental - water, gas & soil analysis Engineering - materials characterisation Crime - forensics (CSI) Sport & leisure - pool chlorination; drugs tests Research Created with MindGenius Business 2005® Analytical Process Formulating the question Selecting analytical procedures Conducting the analysis Sampling Sample preparation calibration of method Sample analysis Collection and processing of data and calculation of errors Created with MindGenius Business 2005® Analytical Process, cont. Method validation Reporting and interpretation (results & discussion) Drawing conclusions (answering the question!) Created with MindGenius Business 2005® Method selection Valid Analytical Measurement (VAM) A result is fit for purpose when its uncertainty maximises its expected utility (cost, usually) reducing uncertainty generally increases the cost of analysis most users have tight budgets uncertainty in measurement should be as large as can be tolerated to keep costs down other factors can affect fitness for purpose sensitivity of technique sample throughput accuracy and precision that is obtainable sample type and preparation Created with MindGenius Business 2005® VAM, cont Ultimately, the results are fit for purpose if they meet the specific needs of the customer, the customer is confident in the results and they represent value for money. Created with MindGenius Business 2005® Valid Analytical Measurement (VAM) Goldmine A sampling and analysis game for Minitab can be found here http://www.rsc.org/Membership/Networking/InterestGroups/Analytical/ AMC/Software/goldmine.asp Created with MindGenius Business 2005® Comparing techniques statistically The F test and Student's t test F test -Is there a significant difference between the precision of two methods? i.e. are the standard deviations of the two methods significantly different? Student’s t test - used to decide if two sets of results are "the same" or to compare a set of results with a known value. You will have learnt these tests in your QS modules, please refresh your memory if you are unsure how to perform it. You will be expected to be able to compare a set of results with a known value, compare two sets of matched results and compare two sets of unmatched results, please see me if you can not do this Further information and worked examples are available on the CH217 studentcentral website Created with MindGenius Business 2005® Samples - sampling strategy Probably the most important stage in any analysis. If the sample taken is not representative of the original material everything you do next is worthless. Created with MindGenius Business 2005® Sample nomenclature lot - quantity of material which is assumed to represent a single population for sampling purposes batch - quantity of material known (or assumed) to have been produced under uniform conditions increments - portions of material obtained using a sampling device from lot/batch primary/gross sample - combination of increments composite/aggregate sample - combination of primary samples laboratory sample - portion of material delivered to lab for analysis test (analytical) portion - material actually submitted for analysis Created with MindGenius Business 2005® Sampling - stages Horwitz. Pure and Applied Chemistry, 1990, 62, 1193-1208. Created with MindGenius Business 2005® Obtaining a representative sample Usually the lot is not homogeneous but may be randomly heterogeneous (different compositions occur on a small scale and randomly) or segregated heterogeneous (large patches of different compositions) A representative sample will not reflect the composition of the target exactly but will be adequate enough to be 'fit for purpose'. There will always be a degree of uncertainty from sampling. Created with MindGenius Business 2005® Sampling - n numbers How many replicate samples do we need to analyse? Often in biology you will come across n=6 for all analyses. so where does this come from? Confidence limits - met in QS modules x ts n Rearrange to make n the subject 2 n t s 2 x 2 Use the acceptable error x and confidence level (to find t) to calculate n. Created with MindGenius Business 2005® Sampling - n numbers Worked Example The concentration of lead in the bloodstream was measured for a sample of children from a large school near a busy main road. A preliminary sampling of 50 children gave a mean concentration of 10.12 ng ml-1 and standard deviation of 0.64 ng ml-1. How big does the sample need to be to give an error of less than ±0.1 ng ml-1 with 95% confidence? For 95% confidence t = 1.96 (n = ∞) 2 n t s 2 x 2 1 . 96 0 . 64 2 0 . 1 2 2 157 . 4 160 So 160 children would need to be tested Created with MindGenius Business 2005® sample preparation Preparing samples for analysis Depends on the form required for analysis Samples may require Moisture control Grinding Dissolving Ashing Fusion Extraction Preconcentration/dilution Derivatisation or a combination of several of these Instruments such as microwave ovens, sonicating baths, pressure vessels (digestion bombs) and extraction cartridges may also be used. Please see recommended reading for further details on these preparation techniques (ch28 Harris) Created with MindGenius Business 2005® solid phase extraction Analyte is removed from sample by passing a solution over a solid. Analyte is adsorbed, or absorbed by the solid and the remaining liquid can be discarded Analyte is eluted by use of a stronger solvent Created with MindGenius Business 2005® solid phase extraction Created with MindGenius Business 2005® Sample storage To keep samples reflective we must prevent contamination & decomposition Problems & Solutions 1. Dirty containers - ensure adequate washing; use disposable containers 2. Type of Container - Avoid “ion-exchange” and adsorption of analyte 3. 4. 5. 6. 7. Light - use brown/foil-covered bottles Air may oxidise sample - store under vacuum, or in a protective atmosphere Moisture - keep tightly sealed Evaporation - keep tightly sealed Heat/cold - store in fridge/temperature controlled room The measures chosen will depend on the analyte and its sample matrix Created with MindGenius Business 2005® Calibration Analytical methods, particularly those using instruments, frequently require calibration procedures These are to establish: the response to known quantities of analyte (standards) within the range used the reliability/drift of the method limits beyond which detection/quantitation is unreliable Calibration normally involves: measurement of samples of known concentrations measurement of a relevant range of concentrations a range in which the response is linear graphical treatment of results modified calculation of errors Created with MindGenius Business 2005® External Standard Simplest and most common form of calibration. Prepare samples containing known quantities of analyte over a relevant range including blanks Controls for sample preparation/matrix should be used, matched to the unknown samples Carry out and record measurements Plot quantity/concentration of analyte vs. response Linear regression with least squares analysis is used to determine response (expressed as y = bx+a) Repeat as and when appropriate (when it is likely that an unacceptable drift will have occurred) Created with MindGenius Business 2005® External Standard Advantages May only need one calibration plot (of 5-10 samples) for 10’s to 100’s of unknown samples Can be easily automated Simple statistics will provide estimates of uncertainty for the method Disadvantages Requires care to match conditions and matrix to that of the unknown samples Does not control for sudden changes in method performance Created with MindGenius Business 2005® External standard You will have done this in more detail in BY131 You should be able to use linear regression to calculate the line of best fit and the errors in the calibration line to calculate the concentration of the analyte and its error from this information (see sec 5.4, 5.5, 5.6 in Miller & Miller) The ability to do this is assumed in this module. Created with MindGenius Business 2005® Internal Standard Useful for methods which are not very reproducible; e.g. Gas chromatography uses very small volumes (<1 ml) difficult to measure accurately The instrument responses to mixtures of known amounts of analyte and of a different compound (internal standard) are measured, and response factor determined A known amount of internal standard is added to the unknown sample. Signals from the analyte and from the internal standard are measured Response factor allows determination of analyte concentration Created with MindGenius Business 2005® Internal Standard Advantages Can control for loss during sample preparation Controls for unexpected changes in method performance Disadvantages Requires suitable reference standard The two compounds (standard and analyte) must be quantifiable independently and have linear responses over a range of concentrations Must account for dilution steps in calculations Created with MindGenius Business 2005® Internal Standard-Worked Example Measurement of caffeine concentration by HPLC, using theophyline as an internal standard. Standard solutions containing a range of known amounts of both caffeine and theophyline are prepared. These are subjected to HPLC and the relative instrument response (area under each peak) is determined, and response factor determined. Absorbance Caffeine Theophyline solution caffeine Conc./mg.l-1 Theophyline Peak area Conc./mg.l-1 Peak area A 1 20000 1 50000 B 2 38400 1 48000 c 4 89600 1 56000 Created with MindGenius Business 2005® Internal Standard-Worked Example Response Factor Analyte signal F Analyte conc . a) 20000 F 1 b) c) 38400 signal standard conc. F 0 .4 1 F 48000 2 1 89600 56000 4 50000 Standard F F 0 .4 F 0 .4 1 In reality there would be some variation and multiple calibration samples would be used to determine precision of response factor A 10ml of a 1mg.L-1 internal standard is added to 10ml of an unknown sample . Instrument signals measured: Analyte: 30,000, Internal Standard: 27,000 Created with MindGenius Business 2005® Internal Standard-Worked Example Response factor allows determination of analyte concentration in sample: Analyte signal F Standard signal standard conc. Analyte conc . 30000 x 0 .4 27000 0.5 x 1 . 39 mg . L 1 Original concentration = 1.39 x 20/10 = 2.78mg.L-1 Created with MindGenius Business 2005® Standard addition Frequently used where matrix effects and interferents are prevalent e.g. atomic absorption/emission Prepare samples containing equal volumes of unknown analyte concentration “Spike” each sample with known, different amounts of standard (same analyte, including a range from 0 to ~5x expected unknown concentration) Dilute all samples to the same volume Carry out and record measurements Plot quantity/concentration of known analyte added vs.. response Linear regression with least squares analysis is used to determine response (expressed as y = bx+a) Concentration of unknown = - (x-intercept) = a/b Repeat for each unknown sample Created with MindGenius Business 2005® Standard addition Advantages Controls for matrix effects Controls for unexpected changes in method performance Disadvantages Requires several measurements for each unknown May use more unknown sample than other methods Must be careful to account for dilution steps in calculations Created with MindGenius Business 2005® Standard addition - Worked Example Measurement of Copper concentration by atomic absorption spectrometry Five 10ml solutions of unknown (approx. 2mg.L-1) copper concentration were prepared and to these was added: 0, 2, 4, 6 and 8 cm3 of 10mg.L-1 standard analyte solution in water (one volume to each flask). All samples diluted to 25cm3 with water and mixed well. The solutions were then measured using AAS and the results recorded Solution Added volume/ cm3 Absorbance 1 0 0.150 2 2 0.312 3 4 0.446 4 6 0.580 5 8 0.762 Created with MindGenius Business 2005® Calculate concentration of copper added to solution, using c1V1 = c2 V 2 i.e. 2 cm3 added: 10 x 2/1000 = c2 x 25/1000 c2 = 0.8 mg.L-1 etc Solution Added volume/ cm3 Absorbance Added concentration/ mg.l-1 1 0 0.150 0 2 2 0.312 0.8 3 4 0.446 1.6 4 6 0.580 2.4 5 8 0.762 3.2 Plot quantity/concentration of known analyte added vs. response, and plot line using linear regression with least square analysis (expressed as y = bx+a) Created with MindGenius Business 2005® 0.1865 ± 0.006028 Y-intercept 0.1516 ± 0.01181 X-intercept -0.8129 S ta n d a r d a d d itio n p lo t 1 .0 x- interc ept = -ve c onc entration of unknown A bso rbance Slope 0 .8 0 .6 0 .4 0 .2 -1 0 1 2 3 4 C o n cen tr atio n ad d ed to sam p le (m g .L Conc. of unknown in samples = - (x-intercept) = a/b = 0.813mg.L-1 -1 ) NB: 10cm3 aliquots of the original solution were diluted to 25cm3 in the samples, so concentration of original solution = 0.813 x 25/10 = 2.0325 ~ 2.03mg.L-1 Created with MindGenius Business 2005® validation Standards Performance parameters Errors in Analysis Record Keeping Created with MindGenius Business 2005® “How long is a piece of string?” The results from any analytical measurement depends upon and is traceable to the measurement standards used in the process. These include standards for mass, volume and amount of a chemical species. Equipment is usually periodically calibrated using standards that can be traced back to an International Primary Standard. Created with MindGenius Business 2005® Example 1. 2. 3. 4. An analytical balance will be calibrated periodically using calibrated weights. These weights are regularly checked against a set of weights held at a reference laboratory. The reference laboratory's weights will be checked periodically against the national standard kilogram (held at the National Physical Laboratory, NPL). This national standard kilogram is occasionally compared to the international standard kilogram. Each stage introduces a measurement uncertainty which has to be taken into account. This means that the standards used in a laboratory will always have a greater uncertainty associated with them than those from the reference laboratories. Created with MindGenius Business 2005® Standard solutions Standard solutions can be used to help with calibration and to compare results against to establish the accuracy of a technique. The two main grades of standard are: Primary Secondary Certified Reference Materials (CRM) - specially prepared samples containing an analyte at a pre-determined concentration . Created with MindGenius Business 2005® Primary standards Primary standards are highly purified compounds that are used, directly or indirectly, to establish the concentration of standard solutions. Primary standards should meet the following requirements: High purity Stability toward air Absence of hydrate water so composition does not change with variations in humidity Ready availability at reasonable cost Reasonable solubility in titration medium Reasonably large molar mass so that relative error associated with weighing the standard is minimised Created with MindGenius Business 2005® Secondary standards There are few compounds that meet these criteria. So often a less pure compound has to be used: secondary standard The ideal standard solution should: Be sufficiently stable that its concentration needs to be determined only once React rapidly with the analyte React more or less completely with the analyte for good end points Undergo selective reaction with simple balanced equation Few reagents meet all of these requirements Created with MindGenius Business 2005® Performance parameters Accuracy – measure of agreement between a single analytical result and the true value Precision – measure of agreement between observed values obtained by repeated application of the same analytical procedure Selectivity – measure of the discriminating power of an analytical procedure in differentiating between the analyte and other components in the test sample Sensitivity – the change of the measured signal as a result of one unit change in the content of the analyte (calculated from the calibration line) Limit of Detection – calculated amount of analyte in the sample which corresponds to 3 times the sd of the blank sample Limit of Quantitation – minimum content of the analyte that can be quantitatively determined with reasonable statistical confidence. Equivalent to 6 time the sd of the blank sample Created with MindGenius Business 2005® Linearity – a measure of the linearity of the calibration Range – concentration range to which the technique is applicable Ruggedness – insensibility of the method for variations during execution Standard deviation and relative standard deviation (RSD) – measures of the spread in the observed values as a result of random errors Repeatability – expected maximum difference between two results of identical test samples obtained under identical conditions Within-lab reproducibility – expected maximum difference between two results obtained by repeated application of the analytical procedure to an identical test sample under different conditions (e.g. different operator, different days) but in the same laboratory Between-lab reproducibility - expected maximum difference between two results obtained by repeated application of the analytical procedure to an identical test sample in different laboratories (e.g. different operators, different instrumentation in different labs on different days using same method Created with MindGenius Business 2005® Errors in Analysis The key to any successful analysis is ensuring that it will “answer the question” No analysis can be absolutely error-free All analyses must be designed to produce acceptable levels of errors and uncertainty The best way to minimise errors is by careful experimental design Created with MindGenius Business 2005® types of error Three main types of error Gross: So serious the experiment must be abandoned. e.g. dropping a key sample, instrumental breakdown Random: When an experiment is repeated as exactly as possible, the replicate results will differ due to random errors. Estimates of random errors gives the precision or reproducibility of the analysis. Systematic: An experimental method gives a reproducible under- or overestimate of the real result. Total of all systematic errors gives the bias of an analysis. Created with MindGenius Business 2005® Typical sources of error May be personal, instrumental or methodological Random Systematic Volume - not reading the burette reproducibly Weight - sensitivity of the balance Volume - glassware not exact; ”indicator errors”; incomplete drainage of pipette/burette; lab temperature Weight - vessel at different temperature to balance; air buoyancy effect Both Incomplete transference between vessels Incomplete reaction, decomposition or moisture absorbance of sample/analyte Interfering species With good tools and careful measurement, traditional methods (gravimetry, titrimetry) are generally more accurate than instrumental method. Created with MindGenius Business 2005® Error Avoidance After considering each stage of the process, employ: Random Errors Systematic errors improved technique (e.g. reading burette volumes) a more accurate balance sufficient repeated measurements (replicates) a different scale (g are easier to weigh than mg) replicates in different glassware temperature controls difference weighing “reference standards” and “blank” measurements purified reagents a different/additional method interlaboratory trials Systematic errors are not always obvious - but the methods above can often be used to detect them! Created with MindGenius Business 2005® Accuracy and precision Accurate and Precise Precise but not accurate Accurate but not precise Inaccurate and Created with MindGenius Business 2005® Imprecise accuracy & precision Uncertainty - A measure of both precision and accuracy, i.e. is an indicator of overall errors associated with the method. May be quoted using s, RSD or CI (should state which) s and RSD should be quoted with the relevant n Analytical results are quoted as a mean ± uncertainty Size of the uncertainty dictates how many significant figures to quote Created with MindGenius Business 2005® Calculating uncertainty Bottom-up method Combine all known errors (e.g. weighing, glassware, reagent purity) to give an estimate of uncertainty Problem: This can be very complex, and it is difficult to include systematic errors Top-down method Conduct multiple replicates of the experiment, varying as many conditions that cause bias as possible - operator, reagent source, glassware etc. - then mathematically estimate the uncertainty. Created with MindGenius Business 2005® Measures of Spread Often quoted as a indicators of uncertainty Range: Difference between highest and lowest values Standard Deviation (s): A good measure of precision. A small s means that the data is more precise than data with a large s but not necessarily more accurate Variance (s2): The square of the standard deviation Coefficient of Variation (CV) OR Relative Standard Deviation (RSD): A relative error estimate expressed as a % of the mean of the measurements. Used to compare the precision of methods with different units/ranges. Confidence interval (CI): A range which has a high statistical likelihood (e.g.95%) of containing the true value Created with MindGenius Business 2005® significant figures You should have covered this in more detail in BY131 (also see Harris 3.1-3.3) Don’t just write down all the digits your calculator gives you! Quote the minimum number of digits needed to write a value in scientific notation without loss of accuracy e.g. 9.34 (±0.02) x 102 not 93400, and not 9.34567 ±0.02 Created with MindGenius Business 2005® Rules Generally only the last digit should have uncertainty associated with it The last digit will always have uncertainty associated with it (unless the data is discrete) Zeros at the end of a number imply you know the value ends in 0 (4.56 is not the same as 4.560) Calculations should be carried out without rounding only round up the answer If you are worried about loss of information you may put an extra digit as a subscript (e.g. 4.562) Use literature examples and common sense if you are unsure! Created with MindGenius Business 2005® propagation of errors Necessary to calculate combined errors for: “bottom up” estimation of uncertainty estimating uncertainty for results based on two or more values each with its own uncertainty e.g. For data reported as ratios Value = (sample result (±error) : control result (±error)) - we cannot simply add the errors - sometimes they will cancel each other out Created with MindGenius Business 2005® Relative and Absolute uncertainties Uncertainties of a measurement x can be quoted as absolute – ex (in same units as x) Relative - %ex ( a percentage of x) Conversion: Relative y uncertaint Absolute uncertaint Measured %e Absolute uncertaint y x ex y 100 % value 100 % x Relative uncertaint y Measured value 100% ex ex x 100 % Created with MindGenius Business 2005® Example Question A sample weight was measured as 5.1g. The balance used was known to be accurate to 0.02g. What is the relative uncertainty associated with this measurement? Relative uncertaint y Absolute uncertaint Measured %e %e %e So, sample weight x ex y 100 % value 100 % x 0.02g x x 0 .4 % 100 % 5 . 10 g 5 . 10 g 0 . 4 % Created with MindGenius Business 2005® How do we combine uncertainties? We can use simple formulae to combine uncertainties Combine one stage at a time e.g. x = (a/b) + c 1) Combine a and b uncertainty, then 2) Combine the result with c to get uncertainty in x NOTE: The methods described here are only used for random errors, and assume that systematic errors have been identified and eliminated Created with MindGenius Business 2005® Combining uncertainties addition and subtraction Where the calculation to find x includes addition or subtraction e.g. x = a+b-c We need to combine the absolute uncertainties for a, b and c, i.e. Combine ea eb and ec Uncertainty in x: 2 2 2 ex e a eb ec Method: Calculate x Calculate ex Quote result as x ± ex Created with MindGenius Business 2005® Example question Uncertainty in reading a burette: You measure a volume by subtracting the initial reading from the final reading. Initial reading is 0.05 (0.02) ml Final reading is 17.88 (0.02) ml If the uncertainty in each reading is known to be 0.02ml what is the volume measured and its overall uncertainty Measured volume is 17.88 - 0.05ml = 17.83ml Absolute uncertainty, ex = Volume =17.83 (±0.03)ml e f ei 8 10 2 2 4 0 . 02 ml 0 . 02 ml 2 2 ml 0 . 02 8 ml 0 . 03 ml Created with MindGenius Business 2005® Combining uncertainties – multiplication and division Where the calculation to find x includes multiplication or division e.g. x = (a×b)/c We need to combine the relative uncertainties for a, b and c, i.e. Combine %ea %eb and %ec Uncertainty in x: 2 2 2 % e x % e a % eb % ec Method: Calculate x Convert absolute uncertainties to relative uncertainties Calculate %ex Convert %ex to ex Quote result as x ± ex Created with MindGenius Business 2005® Example question Calculate the value and uncertainty of x where: x= (a.b)/c and: a = 1.76 ( 0.03), b = 1.89 ( 0.02) and c = 0.59 ( 0.02) Calculate x x 1 . 76 0 . 03 1 . 89 0 . 02 0 . 59 0 . 02 5 . 64 e x Relative uncertainties: %e a e a 100 a 0 . 03 100 1 . 76 1 .7 % % eb e b 100 b 1 .1 % 0 . 02 100 1 . 89 %e c e c 100 c 0 . 02 100 0 . 59 3 .4 % Created with MindGenius Business 2005® Example question cont. Combine Combined Relative % ex % e1 % e 2 % e 3 2 2 2 1 .7 % 1 .1 % 3 .4 % 15 . 66 % 2 2 2 4 .0% Convert to absolute uncertainty Absolute Uncertain ty in x % ex x 100 4 . 0 5 . 64 100 0 .2 3 So, x 5 . 64 0 . 2 3 5 . 6 0 . 2 Created with MindGenius Business 2005® Combining uncertainties – powers and roots Where the calculation to find x includes a power or root e.g. x = ab or x = √a Using relative uncertainties Uncertainty in x: % ex b % e a Method: Express roots as ab e.g. √a = a½ Calculate x Convert ea to %ea Calculate %ex by multiplying by b Convert %ex to ex Quote result as x ± ex Created with MindGenius Business 2005® Example question Calculate the value and uncertainty of x where: x= a3 and a = 1.76 ( 0.03) Express as x = ab x 1 . 76 0 . 03 Calculate x x 1 . 76 5 . 4 5 Convert absolute uncertainty to relative uncertainty 3 3 % ea 0 . 03 100 % 1 . 76 1 .7 % Created with MindGenius Business 2005® Example question, cont. Multiply by b % e x 1 .7 % 3 5 .1 % Convert to absolute uncertainty ex 5 . 1 % 5 . 45 100 % 0 .2 8 So, (using correct s.f.) x 5 .5 0 .3 Created with MindGenius Business 2005® Combining uncertainties constants Where a constant k is part of the calculation, and has no uncertainty associated with it. Rule of thumb: If you are uncertain about the effect of k, include it as a term with an associated uncertainty of 0 Case 1: k is added or subtracted Value and uncertainty of x where x = k + a or x = a - k k does not affect the absolute uncertainty - but will affect relative uncertainty Case 2: k is multiplied or divided Value and uncertainty of x where x = ka or a/k k affects the absolute uncertainty - but not the relative uncertainty Created with MindGenius Business 2005® Combining uncertainties – combinations Solve each type of combination separately, one at a time e.g x = (a + b) c • Combine errors for a + b to get absolute ea+b • Convert ea+b to %ea+b using (a + b) as the measured value • Convert ec to %ec and combine with %ea+b to get %ex • Calculate x • Convert %ex to ex • Answer is expressed as x± ex NOTE: All these examples give ex (absolute uncertainty) as an answer. You may be asked to calculate just %ex (relative uncertainty) Read the question carefully! Created with MindGenius Business 2005® Example question A 50cm3 burette can be read to ± 0.02cm3. In a particular analysis the result is calculated using the formula y = xm/(Ts - Tb) where y is the analyte concentration, in mol.dm-3, and Ts and Tb and the sample and blank titres respectively in cm3. Calculate the uncertainty in the final result when: x = (0.150 ± 0.002) mol.dm-3, m=300, Ts = 15.01 cm3 and Tb = 0.04 cm3. m is known absolutely. Created with MindGenius Business 2005® y = xm/(Ts - Tb) Look at subtraction first Measured volume Ts - Tb = 15.01 - 0.04ml = 14.97ml Calculate eTs-Tb e Ts Tb Convert to %eTs-Tb e Ts e Tb 2 0 . 02 0 . 02 2 8 10 2 4 0 . 02 8 0 . 03 cm % eT s Tb 2 eT s Tb T s Tb 0 . 028 3 100 % 100 % 14 . 97 0 . 18 7 % Created with MindGenius Business 2005® Now look at constant y = xm/(Ts-Tb) m only affects absolute uncertainties for y To calculate ey we will be using relative uncertainties (division) Convert ex to %ex ex % ex 100 % x 0 . 002 100 % 0 . 150 Combine relative uncertainties 1 .3 3 % % ey % eTs Tb % e x 0 . 18 7 1 . 33 1 . 80 2 2 2 2 1 .3 4% Created with MindGenius Business 2005® Calculate y y xm T s Tb 0 . 15 300 14 . 97 3 . 0 1 mol .dm 3 Convert relative uncertainty of y to absolute ey %ey y 100 % 1 . 34 3 . 01 100 % 0 . 04 0 mol .dm So, 3 y 3 . 01 0 . 04 mol .dm 3 Created with MindGenius Business 2005® Limit of Detection (LoD) The concentration which gives an instrument signal (y) significantly different from the blank (or background) signal This is generally calculated as: Concentration x which gives rise to a signal of yB + 3sB where yB and sB are the mean and s.d. of blank solutions NB the method used may vary according to the purpose of the analysis - so it should always be quoted Created with MindGenius Business 2005® Measuring LOD/LOQ Practically Perform the analysis on matched solutions containing no analyte Calculate the mean (yB) and standard deviation (sB) of the signals/measurements obtained BUT this can be very time- and reagent- consuming Mathematically Use the calculated value of the intercept (a) as an estimate of yB Use sy/x as an estimate of sB This is more accurate than using the single blank value included as part of the calibration process, and eliminates the need for repetition Created with MindGenius Business 2005® Sensitivity vs. Detectivity LOD and LOQ are measures of detectivity and are dependent on both the slope and the intercept of the calibration plot Sensitivity is a measure of instrument response to changes in concentration across the entire linear range and is only dependent on the slope of the plot Created with MindGenius Business 2005® Limit of Quantitation (LoQ) The concentration above which precise quantitative measurement is possible This is generally calculated as: Concentration x which gives rise to a signal of yB + 10sB This calculation is often conducted in different ways again the method used should always be quoted Created with MindGenius Business 2005® Record Keeping Ensure results are recorded in a laboratory notebook even if they are available electronically. Enough information should be included to ensure a colleague can repeat the experiment using only your notes. Keep a copy of the notebook (preferably in a separate location). Many employers have their own methods for laboratory record keeping and usually require that each page is signed and dated by both the employee and their line manager. This is useful when it comes to intellectual property rights. Created with MindGenius Business 2005® Record Keeping In general for each experiment include: title and date objectives reaction scheme, if applicable hazard assessment, if necessary method results and calculations, including any instrument readouts and graphs conclusion Created with MindGenius Business 2005® Reporting - Analytical Documentation Used to allow other competent analysts to reproduce the method. Sufficient detail is required to obtain consistent results. Trained and competent personnel are still required even when a full detailed document is available Please see studentcentral website for further details Drawing conclusions In a written report of an experiment you must come to some conclusion about the work Use the information from the statistical tests and performance parameters Pull together all the information Keep the wording ‘analytical’ i.e. use ‘accurate’ and ‘precise’ correctly, and don’t over-generalise Make informed judgements about the technique and compare to other possible techniques Created with MindGenius Business 2005®