DFSS - Intro to CPM

advertisement

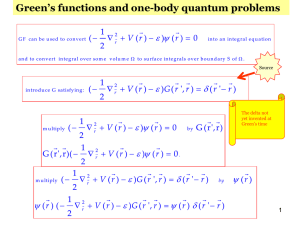

Impacting Design Quality through Key Parameter Development & Management Using KPD&M during Technology & Product Development Processes to Prevent Design Problems Key parameters control financial consequences… through Y & s Physical Law… Y= f(X) DY= f[DX + D(X*N)] + error XY Xs XY&s Cp = (USL-LSL )/6s Cpkl = (Y-LSL)/3s s XNoise Cpku = (USL-Y)/3s Y T $L(Y) = k[s2 + (Y-T)2] …Financial Consequences Intro to KPD&M, Copyright 2010, PDSS Inc. 2 What does the word “Key” mean? Something that is… New Totally new to you & all your competitors, no one has fulfilled the requirement(s) or controlled the parameter(s) before – no experience! Unique The requirement(s) or parameter(s) have been fulfilled or controlled by others but not by you! Difficult The requirement(s) or parameter(s) are extreme & their fulfillment or control is very high in risk Intro to KPD&M, Copyright 2010, PDSS Inc. 3 Things that are NOT “Key”… Something that is… Easy Common Old These are functions, part specifications & mfg. functions that we place under normal Q.C. metrics - Little or no SPC investment (low need to detect & prevent) - Cp & Cpk checked periodically - Use Six Sigma to react to problems in this area Intro to KPD&M, Copyright 2010, PDSS Inc. 4 Refining the term - Key A function, part or material characteristic can be designated as Key = Under Watch! Functions occur in the product or process as it is transforming mass & / or energy… it is what the product or process does. • Inherent in the design of the product or mfg. process Characteristics are static dimensions, shape factors, surface finishes or bulk material properties Key doesn’t just mean it is important! It means there is high risk because… • unproven – we lack facts, little or no data - we don’t know! • unstable & must be “watched”! • dependent on different Design or Supplier’s capabilities Intro to KPD&M, Copyright 2010, PDSS Inc. 5 Key Parameters are like slippery bars of soap! – risk of “getting out of hand”! Risk! Cannot afford to call everything that is merely important a Key Parameter $$$ Intro to KPD&M, Copyright 2010, PDSS Inc. 6 The road to being designated Key… 1. Vary an X & measure the effect on Y…. DY/DX 2. Do so repeatedly & measure the variation around DY caused by each DXi = random error = e 3. Define the ratio between the Signal (DY/DXi) & the Noise e … this is called the F Ratio = Strength of each DXi on DY when compared to random noise in the replicated data 4. Establish if each Xi’s effect on Y is statistically significant… calculate the p value 5. Establish the Capability Index for Ys & Xs… calculate the Cp & Cpk values for Y & X under nominal (Cp) & stressful (Cpk) conditions! Intro to KPD&M, Copyright 2010, PDSS Inc. 7 Stability, F Ratio, p Value, Robustness, Tunability & Capability tell the Story! If Xs & Ys are: statistically significant…. Low p values (< 0.05) have high F Ratios (>> 4) from Analysis of Variance (ANOVA) possess unstable behavior (SPC trend & control issues) have low Cp under nominal conditions… then they are extremely risky & are designated as Keys! These are our highest priority Keys to work on. If these same Xs & Ys possess high sensitivity to stressful noises after Robust Design difficult to tune onto the desired target after Robust Design have low Cpk under stressful conditions… then they are still very risky & are designated as Keys! Intro to KPD&M, Copyright 2010, PDSS Inc. 8 Key >>> NUD! Guilty until proven Innocent! Key parameters are under suspicion – we don’t trust them! measured & watched for drift in mean measured & watched for changes in s X&R Charts A parameter or characteristic can come off our list of Keys…. Re-designated as ECO! Proven stability over time (SPC Charting) Ease of control under nominal & stressful conditions (Robust & Tunable performance) Sustained capability (Cp/Cpk) as cost is reduced Intro to KPD&M, Copyright 2010, PDSS Inc. 9 What is Key Parameter Development & Management? A proactive process for: Identifying Connecting Tracking Refining Documenting a hierarchy of: Key requirements & the integrated set of measured functions, specifications & set points - down through a product architecture and its production & support processes. Preventing problems Intro to KPD&MM, Copyright 2010 PDSS Inc. 10 A bit of history…. From Dogma & Faith… Dogma = Cheaper & Faster – We must Hurry!!! Faith = We X You will make it! To Doubt & Experimentation… Doubt = We have risk & uncertainty – we need facts! Experimentation = We can & will take the time to learn! Learning generates facts which reduce uncertainty & lower risk… …but not by rushing & cutting corners. Intro to KPD&M, Copyright 2010, PDSS Inc. 11 Some personal history… Dogma & Faith results circa. 1972-1994 compared to Doubt & Experimentation results from 1995-1999 at Kodak… A focused effort was implemented in Kodak’s digital printing business unit on the DigiMaster Project: Our 1st ever Commercial Systems Engineering Org., Center of Excellence & SE Process Comprehensive integration of Key Parameter Development & Mgt. approach into Phase-Gate PDP • Clear definition of “Key” Customer needs • Heavy emphasis on Reliability Development using Robust Design • Detailed “Design for X” focus on produceability & serviceability Strong Project Manager, rigorous PM methods & dedicated, accountable PDT (functional Centers of Excellence supported it) Intro to KPD&M, Copyright 2010, PDSS Inc. 12 The DigiMaster 9100 digital printing system Over 10,000 parts < 30 major subsystems (chemo-opto-mechatronics) Req’d 6s image quality across 15 measurable attributes Req’d 150K MIBSC within 95% Confidence Limits Historic example of Prod. Dev. Team performance before the use of SE & KP enabled work flow… MTBF Pre-SE, KPD, DFSS, etc. System integration too early… Targets Independent SS Changes to improve System Performance Change over to supplier mtl.s & parts Late integration of tweeked SSs & purchased accessories 50-60% of Target Gate 2 14 Gate 4 Gate 3 Time Gate 5 Development Teams can improve results with SE, Key Parameter Development & select DFSS tools… SE/KPD/DFSS Actual Pre-SE, KPD, DFSS, etc. +2s UCL Target >95% of Target MTBF -2s LCL 50-60% of Target Gate 2 15 Gate 4 Gate 3 Time Gate 5 Duane plot from an actual project 16 What made the difference? Macro-effects Created a formal systems engineering organization • - clear SE roles, with SE tools, tasks & deliverables tied to Gate Requirements measured with performance score cards – not checklists Enhanced the SE team to actively use specific KP tasks with DFSS tools to complete the tasks, • directly assisting sub-teams – producing the right SE Gate deliverables Micro-effects Key Parameter Mgt.: clear definition of Key reqts. flow down & rigorous measurement of capability flow-up (Cp & Cpk trace-ability) System Integration, system sensitivity analysis & reliability testing only AFTER subsystem & subassy. robustness optimization was completed • Complete story is in Ch. 7: Systems Architecting, Engineering & Integration using DFSS & Key Parameter Development reliability development vs. assessment 17 What does System Development look like as a flow of work over time? The Super-set of System Engineering Macro- Functions: Architecting Internal & External Needs System Functions System Reqts. Engineering System Modeling System Architecture Subsystem Interface Development & Robustness Optimization Integration Assessment & Validation System Performance System KPM Balancing Database System Transfer to System Integration Internal & Production, & Stress Service & External Testing Tech. Validation Support Flow of System Architecting, Engineering, Integration & Assessment Tasks 18 Process Map of Major System Architecting, Engineering, Integration & Assessment Tasks 19 Define System Reqts Define System Functions Define System Architecture Partition System into Subsystems Create & build KPM Database Generate System FMEA Lead System Integration Meetings Develop System Noise Map Balance Interface Sensitivities – create latitude Define System Integration DOEs &Test Plans Integrate System Test Rigs & Data Acq. System Conduct System Integration Stress Tests Balance System Performance Conduct Reliability Assessments Validate System Performance Transfer KPM Database to Mfg. & Support Key Parameter Enabled Systems & Design Engineering: Key Parameter Dev. process & enabling DFSS tools Design Concept Optimize Verify Key Parameter Management Process Requirements Development Process Full KPD&M details: Ch.s 8-13 of DFSS text Concept Design Process Sequential Design of Experiments Process Reliability Definition, Modeling, Development & Assessment Process Design for “X” Process - Manufacturing, Assembly & Cost; Service Maint. & Support - Environment, Health, Safety, Legal & Regulatory 20 Allocated Reqt.s Flow-down & Measured Capability Roll-up VOC Needs Product Reqts. Subsystem Reqts. Verification & Preventive / Contingent Action Process Subassembly Reqts. Component Reqts. Flow down of the reqts to be fulfilled through the measurement of KFRs & KPs 21 Mfg. Process Reqts. Customer Satisfaction Product CFR Cp & Cpk Subsystem CFR Cp & Cpk Subassembly CFR Cp & Cpk Component Spec. Cp & Cpk Mfg. Process Cp & Cpk Roll-up of Cp & Cpk through the measurement of KFRs & KPs Requirements Development Process …Flow-down of NUD / Kano requirements to be fulfilled VOC Needs HOWs: Measurable Technical Requirements m in. of 2 7 p ictu res H igh app earanc e ra tin g 0. 0 C arry ing me cha nis m 35 mm film 0. 0 0. 0 Fl ash pow er V iew find er A rea V iew find ing ind icat or g rap hics C am era w e ight L abe l cla rity W ind ing forc e S nap force F lash re -cha rge tim e F lash fo rce Su rfa ce roug hne ss Bo dy con tou ring 0. 0 Similar to 35 0. 0 0. 0 0. 0 0. 0 0. 0 0. 0 C u sto m e r Im po rta nce 0. 0 U MC Im pa ct f orce re sist anc e E xte rnal dim en sion s Sn ap load res is tan c e D ens ity C olor Satu ratio n M axim ize pa rt re -us e Lo w G rain Co ntra s t 0. 0 0. 0 0. 0 0. 0 0. 0 Product Reqts. Enabling Tools. Methods & Best Practices: Customer Assessment Ease of Use 0. 0 General Features Image Quality OTU Camera Example Go od Im a ge Qu ality Direction of Improvement V V W S S S S S S W W V W V V S W S S V W W W W W S Ea s y to us e W W U niq ue F ea ture s V S V W V V W H A Ts for On e-Ti m e -U s e C am era (V O C Inp ut D ata ) S V W V V R egular 35 mm Ca mer a pe rform an c e S V W V V V W Clear Pictures 16.0 Low Graininess 11.0 Pictures can't be "washed out" 5.0 Can't mis-fire when I put it away in my pocket or purse 4.0 Has to be durable if I drop it 12.0 Low purchase price 15.0 Must fit in my shirt pocket 2.0 Want to take pictures in any light 6.0 Has to be really easy to use 14.0 Easy to wind 1.0 Large view finder that helps me get pictures centered easily 10.0 Has to be light & easy to carry 13.0 Prefer 35 mm format 8.0 Has to be close to my 35mm in picture quality 9.0 Has to take a minimum of 27 3.0 I don't want it to look cheap 7.0 -Customer Interviewing How Much 0. 0 0. 0 0. 0 0. 0 0. 0 0. 0 Weighted Importance 0. 0 Te chn ica l A s se ssm en t Organizational Difficulty Relative Importance HOWs: Measurable Technical Requirements m in. of 2 7 p ictu res H igh app earanc e ra tin g 0. 0 C arry ing me cha nis m 35 mm fi lm 0. 0 0. 0 Fl ash pow er V iew find er A rea V iew find ing ind icat or g rap hics C am era w e ight L abe l cla rity W ind ing forc e S nap force E xte rnal dim en sion s F lash re -cha rge tim e F lash fo rce Su rfa ce roug hne ss Bo dy con tou ring 0. 0 Similar to 35 0. 0 0. 0 0. 0 0. 0 0. 0 0. 0 0. 0 Im pa ct f orce re sist anc e U MC M axim ize pa rt re -us e 0. 0 C u sto m e r Im po rta nce Sn ap load res is tan c e D ens ity C olor Satu ratio n Co ntra s t Lo w G rain 0. 0 0. 0 0. 0 0. 0 Customer Assessment Ease of Use Go od Im a ge Qu ality Direction of Improvement V V W S S S W S S V V S V V W V W W V W V V S W S S V W W W W W S U niq ue F ea ture s V S V W Ea s y to us e S V W R egular 35 mm Ca mer a pe rform an c e S V W V W H A Ts for On e-Ti m e -U s e C am era (V O C Inp ut D ata ) Subsystem Reqts. 0. 0 General Features Image Quality OTU Camera Example V W Clear Pictures 16.0 Low Graininess 11.0 Pictures can't be "washed out" 5.0 Can't mis-fire when I put it away in my pocket or purse 4.0 Has to be durable if I drop it 12.0 Low purchase price 15.0 Must fit in my shirt pocket 2.0 Want to take pictures in any light 6.0 Has to be really easy to use 14.0 Easy to wind 1.0 Large view finder that helps me get pictures centered easily 10.0 Has to be light & easy to carry 13.0 Prefer 35 mm format 8.0 Has to be close to my 35mm in picture quality 9.0 Has to take a minimum of 27 3.0 I don't want it to look cheap 7.0 -KJ Analysis How Much 0. 0 0. 0 0. 0 0. 0 0. 0 0. 0 Weighted Importance 0. 0 Te chn ica l A s se ssm en t Organizational Difficulty HOWs: Measurable Technical Requirements Customer Assessment Relative Importance m in. of 2 7 p ictu res H igh app earanc e ra tin g 35 mm film 0. 0 0. 0 0. 0 Fl ash pow er V iew find ing ind icat or g rap hics C am era w e ight C arry ing me cha nis m L abe l cla rity V iew find er A rea W ind ing forc e S nap force F lash re -cha rge tim e 0. 0 0. 0 0. 0 U MC E xte rnal dim en sion s Bo dy con tou ring 0. 0 Similar to 35 0. 0 Im pa ct f orce re sist anc e F lash fo rce Sn ap load res is tan c e Su rfa ce roug hne ss 0. 0 0. 0 C olor Satu ratio n M axim ize pa rt re -us e Lo w G rain Co ntra s t 0. 0 Ease of Use 0. 0 0. 0 0. 0 0. 0 0. 0 0. 0 C u sto m e r Im po rta nce D ens ity OTU Camera Example 0. 0 General Features Image Quality -NUD Screening & Kano Analysis Go od Im a ge Qu ality Direction of Improvement V W S V S W S S V W W W W W S V W 5.0 4.0 12.0 15.0 2.0 6.0 Has to be really easy to use 14.0 Easy to wind 1.0 Large view finder that helps me get pictures centered easily 10.0 Has to be light & easy to carry 13.0 Prefer 35 mm format 8.0 Has to be close to my 35mm in picture quality 9.0 Has to take a minimum of 27 3.0 I don't want it to look cheap 7.0 How Much Organizational Difficulty Weighted Importance 0. 0 V Must fit in my shirt pocket Want to take pictures in any light 0. 0 V W 11.0 Has to be durable if I drop it Low purchase price 0. 0 W W 16.0 Pictures can't be "washed out" Can't mis-fire when I put it away in my pocket or purse 0. 0 V Clear Pictures Low Graininess 0. 0 S Ea s y to us e S S W W H A Ts for On e-Ti m e -U s e C am era (V O C Inp ut D ata ) W U niq ue F ea ture s V S V W V 0. 0 S S V W V V R egular 35 mm Ca mer a pe rform an c e V W V V Te chn ica l A s se ssm en t Subassembly Reqts. V S S Relative Importance HOWs: Measurable Technical Requirements m in. of 2 7 p ictu res -QFD H igh app earanc e ra tin g V iew find ing ind icat or g rap hics C am era w e ight C arry ing me cha nis m 35 mm fi lm Fl ash pow er L abe l cla rity Similar to 35 V iew find er A rea W ind ing forc e S nap force F lash re -cha rge tim e E xte rnal dim en sion s Bo dy con tou ring Im pa ct f orce re sist anc e U MC F lash fo rce Sn ap load res is tan c e Customer Assessment Ease of Use Su rfa ce roug hne ss C u sto m e r Im po rta nce C olor Satu ratio n D ens ity Co ntra s t Lo w G rain M axim ize pa rt re -us e General Features Image Quality OTU Camera Example Go od Im a ge Qu ality Direction of Improvement V V W S V 2.0 Want to take pictures in any light 6.0 Has to be really easy to use 14.0 Easy to wind 1.0 Large view finder that helps me get pictures centered easily 10.0 Has to be light & easy to carry 13.0 Prefer 35 mm format 8.0 Has to be close to my 35mm in picture quality 9.0 Has to take a minimum of 27 3.0 I don't want it to look cheap 7.0 How Much 0. 0 0. 0 0. 0 0. 0 0. 0 0. 0 0. 0 0. 0 0. 0 0. 0 0. 0 0. 0 0. 0 Weighted Importance 0. 0 Te chn ica l A s se ssm en t Organizational Difficulty 0. 0 S 15.0 0. 0 V W 12.0 0. 0 V S W W W 4.0 0. 0 V W W 5.0 Low purchase price Must fit in my shirt pocket 0. 0 V W S S 11.0 Can't mis-fire when I put it away in my pocket or purse Has to be durable if I drop it 0. 0 W W W Ea s y to us e W V W H A Ts for On e-Ti m e -U s e C am era (V O C Inp ut D ata ) S V V R egular 35 mm Ca mer a pe rform an c e V V Low Graininess Pictures can't be "washed out" 0. 0 S S 0. 0 W U niq ue F ea ture s V S V W 0. 0 S S V W 16.0 0. 0 Component Reqts. S S V W V Clear Pictures Relative Importance HOWs: Measurable Technical Requirements m in. of 2 7 p ictu res H igh app earanc e ra tin g 0. 0 C arry ing me cha nis m 35 mm fi lm 0. 0 0. 0 Fl ash pow er V iew find er A rea V iew find ing ind icat or g rap hics C am era w e ight L abe l cla rity W ind ing forc e S nap force E xte rnal dim en sion s F lash re -cha rge tim e 0. 0 Similar to 35 0. 0 U MC F lash fo rce Su rfa ce roug hne ss Bo dy con tou ring 0. 0 0. 0 0. 0 0. 0 0. 0 M axim ize pa rt re -us e Customer Assessment Ease of Use 0. 0 Im pa ct f orce re sist anc e 0. 0 Sn ap load res is tan c e Lo w G rain 0. 0 0. 0 C u sto m e r Im po rta nce D ens ity C olor Satu ratio n Co ntra s t 0. 0 0. 0 0. 0 General Features Image Quality OTU Camera Example Go od Im a ge Qu ality Direction of Improvement V V W S S 22 S S V W W W W W S V W 4.0 12.0 15.0 2.0 6.0 Has to be really easy to use 14.0 Easy to wind 1.0 Large view finder that helps me get pictures centered easily 10.0 Has to be light & easy to carry 13.0 Prefer 35 mm format 8.0 Has to be close to my 35mm in picture quality 9.0 Has to take a minimum of 27 3.0 I don't want it to look cheap 7.0 How Much Organizational Difficulty Weighted Importance Relative Importance 0. 0 W 5.0 Must fit in my shirt pocket Want to take pictures in any light 0. 0 V S 11.0 Has to be durable if I drop it Low purchase price 0. 0 V 16.0 Pictures can't be "washed out" Can't mis-fire when I put it away in my pocket or purse 0. 0 V W Clear Pictures Low Graininess 0. 0 W Ea s y to us e V W H A Ts for On e-Ti m e -U s e C am era (V O C Inp ut D ata ) S W R egular 35 mm Ca mer a pe rform an c e S S W Te chn ica l A s se ssm en t Mfg. Process Reqts. W U niq ue F ea ture s V S V W V 0. 0 S S V W V V 0. 0 S V W V V -Requirements Trace-ability & Documentation (DOORS, etc.) System Concept Design Process Step 1: External Needs Gathering, Processing & Validating the Voices of the Customer, Marketing, Technology & Business Step 2: Internal Requirements & Constraints Generating & documenting a system of NUD / Kano requirements in a Key Parameter Mgt. data base Step 3: Innovation, Architecting & Solutions Concept Generation, Feasibility Evaluations & final Concept Selection 23 Metrics for Requirements Can be Compared to Measures of Sample Data Cp USL LSL Cp 6s What is Required? Customer Level (USL – LSL) System Level (USL – LSL) Subsystem Level (USL – LSL) Subassembly Level (USL – LSL) Component Level (USL – LSL) Mfg. Process Level (USL – LSL) USL LSL s What is 6Measured? Customer Level (Avg & σ) System Level (Avg & σ) Subsystem Level (Avg & σ) Subassembly Level (Avg & σ) Component Level (Avg & σ) Mfg. Process Level (Avg & σ) From this comparison we can document performance Capability Cp USL LSL P ro c e s s C a p a b ility A n a ly s is fo r C 2 LSL 1 2 .0 0 0 0 T a rg e t W ith in * LS L 8 .0 0 0 0 Me a n 9 .9 7 6 6 S a m p le N 6s US L P ro c e s s D a ta US L O v e ra ll 100 S tD e v (W ith in ) 0 .4 4 7 1 3 4 S tD e v (O ve ra ll) 0 .4 5 8 1 8 6 P o te n tia l (W ith in ) C a p a b ility Cp 1 .4 9 CPU 1 .5 1 CPL 1 .4 7 C pk 1 .4 7 C pm * O ve ra ll C a p a b ility Pp PPU 8 9 10 O b s e rve d P e rfo rm a n c e 11 12 E xp . "W ith in " P e rfo rm a n c e E xp . "O ve ra ll" P e rfo rm a n c e 1 .4 6 P P M < LS L 0 .0 0 P P M < LS L 4 .9 2 P P M < LS L 1 .4 7 P P M > US L 0 .0 0 P P M > US L 3 .0 2 P P M > US L PPL 1 .4 4 P P M T o ta l 0 .0 0 P P M T o ta l 7 .9 4 P P M T o ta l P pk 1 .4 4 8 .0 1 5 .0 3 1 3 .0 4 P ro c e s s C a p a b ility A n a ly s is fo r C 2 X LSL USL X C pk Min , 3s 3s Intro to KPD&M, Copyright 2010, PDSS Inc. LSL US L P ro c e s s D a ta US L 1 2 .0 0 0 0 T a rg e t W ith in * LS L 8 .0 0 0 0 Me a n 9 .9 7 6 6 S a m p le N O v e ra ll 100 S tD e v (W ith in ) 0 .4 4 7 1 3 4 S tD e v (O ve ra ll) 0 .4 5 8 1 8 6 P o te n tia l (W ith in ) C a p a b ility Cp 1 .4 9 CPU 1 .5 1 CPL 1 .4 7 C pk 1 .4 7 C pm * O ve ra ll C a p a b ility Pp 8 9 10 O b s e rve d P e rfo rm a n c e 1 .4 6 P P M < LS L 0 .0 0 11 E xp . "W ith in " P e rfo rm a n c e P P M < LS L 4 .9 2 12 E xp . "O ve ra ll" P e rfo rm a n c e P P M < LS L PPU 1 .4 7 P P M > US L 0 .0 0 P P M > US L 3 .0 2 P P M > US L PPL 1 .4 4 P P M T o ta l 0 .0 0 P P M T o ta l 7 .9 4 P P M T o ta l P pk 1 .4 4 8 .0 1 5 .0 3 1 3 .0 4 24 Reqt. Allocation & KP Measuring down through the System to Subsystems, Sub Assemblies, Parts & Mfg. Processes! V V V V S S S W S V S S V S V V V V V V V V V W V V V V V S W S W V V V S S W V S V V HOWs: Measurable Technical Requirements S S W S S S W W W V W V V S V W S W W S W W S R egular 35 mm Ca mer a pe rform an c e W U niq ue F ea ture s V S V W V V Ea s y to us e S V W V V W H A Ts for On e-Ti m e -U s e C am era (V O C Inp ut D ata ) S V W V V V W 4.0 Has to be durable if I drop it 12.0 Low purchase price 15.0 Must fit in my shirt pocket 2.0 Want to take pictures in any light 6.0 Has to be really easy to use 14.0 Easy to wind 1.0 Large view finder that helps me get pictures centered easily 10.0 Has to be light & easy to carry 13.0 Prefer 35 mm format Customer Assessment I Similar to 35 m in. of 2 7 p ictu res K H igh app earanc e ra tin g K V iew find er A rea K V iew find ing ind icat or g rap hics K C am era w e ight K C arry ing me cha nis m J S nap force H K L abe l cla rity F K F lash re -cha rge tim e F I W ind ing forc e F K F lash fo rce I 35 mm fi lm K F Su rfa ce roug hne ss J F Bo dy con tou ring K F Ease of Use Fl ash pow er K F U MC K E xte rnal dim en sion s C u sto m e r Im po rta nce 5.0 Im pa ct f orce re sist anc e 11.0 Sn ap load res is tan c e Low Graininess Pictures can't be "washed out" Can't mis-fire when I put it away in my pocket or purse D ens ity W 16.0 C olor Satu ratio n V S Clear Pictures Lo w G rain Go od Im a ge Qu ality Direction of Improvement V Co ntra s t OTU Camera Example M axim ize pa rt re -us e General Features Image Quality K K J K K K I F F F H F F H H F H H H F H G F F F F H F G H H H H H 9.0 F F F F 3.0 7.0 2 3 F G F F F G G F H F H F F H 5 QXY F F F H F F YX Q QXY G A H H F F G F A A XQ Y G AQ XY G A YX Q F AX F A Y Q X YQ F F Q A Y X F H G F Key Reqt.s Allocation & Linkage X Q Y H H H A F G G F G 4 A QX Y A Q XY A G G F 8.0 1 G H F I don't want it to look cheap Kon ica Our C am era C o. Fuj i Store B ran ds A QXY H F Has to be close to my 35mm in picture quality 0 F F Has to take a minimum of 27 Q X Y A F A XY Q F A Y X Q F A X QY How Much Te chn ica l A s se ssm en t Organizational Difficulty Q Y A X Kon ica V 5 V Fuj i 4 Store B ran ds Our C am era C o. V 3 V S S 2 S 1 W 0 27 . 57 V S S 33 22 19 22 29 19 37 14 19 13 14 17 28 24 14 34 78 . 36 16 29 29 S 29 Weighted Importance V S Relative Importance V V V V V V V V V W V V V V V S W S W V V V S S W V S V V HOWs: Measurable Technical Requirements V S V W W W S V W 2.0 6.0 Has to be really easy to use 14.0 K J K Easy to wind 1.0 10.0 H H 13.0 F H H H H F F F 7.0 Our C am era C o. Fuj i Store B ran ds 1 2 3 H G F F F F 5 A QX Y F F F H F H F H H F F F F F F F F F G G F H G QXY YX Q QXY G A H H F F G F A XQ Y G AQ XY G A YX Q F F A X Q Y H G G G 4 A A G F H G H F 3.0 Kon ic a A Q XY G G H H 9.0 0 A QXY H G H 8.0 I don't want it to look cheap Q X Y A F H F Has to be close to my 35mm in picture quality I F F Has to take a minimum of 27 K F H F Has to be light & easy to carry K F F Prefer 35 mm format H igh app earanc e ra tin g C am era w e ight C arry ing me cha nis m K m in. of 2 7 p ictu res I F F Large view finder that helps me get pictures centered easily Similar to 35 L abe l cla rity K V iew find er A rea K V iew find ing ind icat or g rap hics W ind ing forc e S nap force K 35 mm film Su rfa ce roug hne ss Bo dy con tou ring Fl ash pow er E xte rnal dim en sion s F lash re -cha rge tim e Im pa ct f orce re sist anc e U MC C olor Satu ratio n Sn ap load res is tan c e D ens ity M axim ize pa rt re -us e Co ntra s t Lo w G rain C u sto m e r Im po rta nce 15.0 Customer Assessment K 22 V W W Low purchase price Must fit in my shirt pocket K F F Want to take pictures in any light J 19 V W S S F H Ease of Use K 22 W W 12.0 F F K 29 V W 4.0 F F I 19 W Can't mis-fire when I put it away in my pocket or purse Has to be durable if I drop it F F K 37 S S V Ea s y to us e W V V W H A Ts for On e-Ti m e -U s e C am era (V O C Inp ut D ata ) W V V R egular 35 mm Ca mer a pe rform an c e S U niq ue F ea ture s V S V 5.0 I 14 S S 11.0 K 24 Go od Im a ge Qu ality S V W 16.0 J 14 S S V W Clear Pictures Low Graininess Pictures can't be "washed out" K 34 W K 16 V V K F lash fo rce General Features Image Quality OTU Camera Example Direction of Improvement AX F A Y Q X YQ F F Q A Y X F H A XY Q H F A Y X Q V V F A X QY V V S S S How Much W S V S S V Te chn ica l A s se ssm en t Organizational Difficulty Q Y A X Kon ic a S 5 V V 4 V V V V 3 V W 2 V V V V 1 33 27 . 57 19 13 14 17 28 78 . 36 29 29 29 S W V V V S W 0 Weighted Importance V V Fuj i Store B ran ds Our C am era C o. V S S W V S V V Relative Importance HOWs: Measurable Technical Requirements Easy to wind 1.0 Large view finder that helps me get pictures centered easily 10.0 Has to be light & easy to carry 13.0 Prefer 35 mm format Customer Assessment K K J K H F H H F F F F F H F G H H H F F F F 2 3 F F F G G H G G G F F 5 QXY YX Q QXY G A H A XQ Y G AQ XY G F H F H F F F G H F F F F F G F A YX Q F F A X Q Y H H H G 4 A QX Y A F H F G H H 1 A G G F 7.0 Kon ica Our C am era C o. Fuj i Store B ran ds A Q XY G H F 3.0 0 A QXY H F 9.0 Q X Y A F F 8.0 I H H H I don't want it to look cheap K F F F Has to be close to my 35mm in picture quality K F F Has to take a minimum of 27 m in. of 2 7 p ictu res I H igh app earanc e ra tin g Similar to 35 C am era w e ight K C arry ing me cha nis m K L abe l cla rity K V iew find er A rea K V iew find ing ind icat or g rap hics W ind ing forc e S nap force F lash fo rce K F 35 mm fi lm J Bo dy con tou ring K Su rfa ce roug hne ss K Fl ash pow er E xte rnal dim en sion s Sn ap load res is tan c e Im pa ct f orce re sist anc e C olor Satu ratio n U MC D ens ity H M axim ize pa rt re -us e F I 22 14.0 Co ntra s t C u sto m e r Im po rta nce 6.0 Lo w G rain Go od Im a ge Qu ality V 2.0 F K 19 S W 15.0 Has to be really easy to use F I 22 V W W 12.0 Must fit in my shirt pocket Want to take pictures in any light K F 29 V S W W Has to be durable if I drop it Low purchase price J F 19 V W S S 4.0 K F 37 V W W 5.0 K F 14 S W Ea s y to us e S S W W H A Ts for On e-Ti m e -U s e C am era (V O C Inp ut D ata ) W W U niq ue F ea ture s V S V W V V Pictures can't be "washed out" Can't mis-fire when I put it away in my pocket or purse K 24 S S V W V V R egular 35 mm Ca mer a pe rform an c e V W V V Low Graininess 11.0 14 W S 16.0 34 Product or System Level V S S Clear Pictures 16 Direction of Improvement V Ease of Use F lash re -cha rge tim e General Features Image Quality OTU Camera Example AX F A Y Q X YQ F F Q A Y X F A XY Q V H H F A V Y X Q V V F A X S S W S Te chn ica l A s se ssm en t Q Y A X V Kon ica S a m p le N 0 .4 4 7 1 3 4 0 .4 5 8 1 8 6 * O ve ra ll C a p a b ility Pp PPU O v e ra ll 8 9 10 O b s e rve d P e rfo rm a n c e 11 E xp . "W ith in " P e rfo rm a n c e 12 E xp . "O ve ra ll" P e rfo rm a n c e 1 .4 6 P P M < LS L 0 .0 0 P P M < LS L 4 .9 2 P P M < LS L 1 .4 7 P P M > US L 0 .0 0 P P M > US L 3 .0 2 P P M > US L PPL 1 .4 4 P P M T o ta l 0 .0 0 P P M T o ta l 7 .9 4 P P M T o ta l 1 .4 4 8 .0 1 5 .0 3 1 3 .0 4 P ro c e s s C a p a b ility A n a ly s is fo r C 2 LSL US L P ro c e s s D a ta US L 1 2 .0 0 0 0 T a rg e t LS L W ith in * 8 .0 0 0 0 Me a n O v e ra ll 9 .9 7 6 6 S a m p le N 100 S tD e v (W ith in ) 0 .4 4 7 1 3 4 S tD e v (O ve ra ll) 0 .4 5 8 1 8 6 m in. of 2 7 p ictu res H igh app earanc e ra tin g V iew find ing ind icat or g rap hics C am era w e ight J C arry ing me cha nis m L abe l cla rity V iew find er A rea W ind ing forc e S nap force F lash fo rce Bo dy con tou ring K 35 mm fi lm Su rfa ce roug hne ss C u sto m e r Im po rta nce E xte rnal dim en sion s Fl ash pow er Im pa ct f orce re sist anc e Sn ap load res is tan c e U MC C olor Satu ratio n M axim ize pa rt re -us e Co ntra s t Lo w G rain K K K K I Q X Y A Kon ica Our C am era C o. Fuj i V Store B ran ds V V V F S S V 2 3 4 5 V CPU V Want to take pictures in any light 6.0 Has to be really easy to use 14.0 Easy to wind 1.0 F G G F F H A XQ Y V V H F F F F H F F F F G H H G W AQ XY G A YX Q S S S Large view finder that helps me get pictures centered easily 10.0 Has to be light & easy to carry 13.0 Prefer 35 mm format 8.0 H H H H F F Has to be close to my 35mm in picture quality 9.0 F F F F F F V G F G F G F F H AX Y Q S W S H F F F F A V W S V V W V W W V V V S 3.0 H H F A Y X Q W S S 7.0 G H G H F F F F F G S V V Q A Y X A XY Q W Has to take a minimum of 27 S W X YQ V I don't want it to look cheap V S V H F F A X QY V W W W W W S Clear Pictures 16.0 Low Graininess 11.0 Pictures can't be "washed out" 5.0 Can't mis-fire when I put it away in my pocket or purse 4.0 Has to be durable if I drop it 12.0 Low purchase price 15.0 Must fit in my shirt pocket 2.0 Want to take pictures in any light 6.0 Has to be really easy to use 14.0 Easy to wind 1.0 Large view finder that helps me get pictures centered easily 4 K K J K F F F F F F F H V I K I K F * 8 9 10 O b s e rve d P e rfo rm a n c e 1 .4 6 P P M < LS L 0 .0 0 11 E xp . "W ith in " P e rfo rm a n c e P P M < LS L 4 .9 2 0 .0 0 P P M > US L 3 .0 2 P P M > US L 0 .0 0 P P M T o ta l 7 .9 4 P P M T o ta l P ro c e s s C a p a b ility A n a ly s is fo r C 2 LSL 1 2 .0 0 0 0 1 .4 9 CPU 1 .5 1 1 .4 7 1 .4 7 C pm * O ve ra ll C a p a b ility Pp Capability Assessment & Traceability 8 9 10 O b s e rve d P e rfo rm a n c e 1 .4 6 P P M < LS L 0 .0 0 11 E xp . "W ith in " P e rfo rm a n c e P P M < LS L 4 .9 2 12 E xp . "O ve ra ll" P e rfo rm a n c e P P M < LS L PPU 1 .4 7 P P M > US L 0 .0 0 P P M > US L 3 .0 2 P P M > US L PPL 1 .4 4 P P M T o ta l 0 .0 0 P P M T o ta l 7 .9 4 P P M T o ta l P pk 1 .4 4 8 .0 1 5 .0 3 1 3 .0 4 K K I F F F F H F H G H H H H 9.0 F F F F F F G F H F H F F F G H F F F F F G F Te chn ica l A s se ssm en t 27 . 33 57 22 19 22 29 19 37 14 19 13 14 17 28 24 78 . 14 34 16 36 29 29 29 W ith in O v e ra ll 1 .4 9 CPU 1 .5 1 CPL 1 .4 7 1 .4 7 C pm * O ve ra ll C a p a b ility Pp 8 9 10 O b s e rve d P e rfo rm a n c e 1 .4 6 P P M < LS L 0 .0 0 11 E xp . "W ith in " P e rfo rm a n c e P P M < LS L 4 .9 2 Mfg. Level 12 E xp . "O ve ra ll" P e rfo rm a n c e P P M < LS L PPU 1 .4 7 P P M > US L 0 .0 0 P P M > US L 3 .0 2 P P M > US L PPL 1 .4 4 P P M T o ta l 0 .0 0 P P M T o ta l 7 .9 4 P P M T o ta l P pk 1 .4 4 8 .0 1 5 .0 3 1 3 .0 4 P ro c e s s C a p a b ility A n a ly s is fo r C 2 LSL US L P ro c e s s D a ta US L 1 2 .0 0 0 0 LS L W ith in * 8 .0 0 0 0 Me a n O v e ra ll 9 .9 7 6 6 S a m p le N 100 S tD e v (W ith in ) 0 .4 4 7 1 3 4 S tD e v (O ve ra ll) 0 .4 5 8 1 8 6 P o te n tia l (W ith in ) C a p a b ility Cp 1 .4 9 CPU 1 .5 1 CPL 1 .4 7 C pk 1 .4 7 C pm * O ve ra ll C a p a b ility Pp 8 9 10 O b s e rve d P e rfo rm a n c e 1 .4 6 P P M < LS L 0 .0 0 11 E xp . "W ith in " P e rfo rm a n c e P P M < LS L 4 .9 2 12 E xp . "O ve ra ll" P e rfo rm a n c e P P M < LS L PPU 1 .4 7 P P M > US L 0 .0 0 P P M > US L 3 .0 2 P P M > US L PPL 1 .4 4 P P M T o ta l 0 .0 0 P P M T o ta l 7 .9 4 P P M T o ta l P pk 1 .4 4 8 .0 1 5 .0 3 1 3 .0 4 25 A YX Q AX F A Y Q X YQ Q A Y X A XY Q F A F 27 . 33 57 19 13 14 17 28 78 . 36 29 US L P o te n tia l (W ith in ) C a p a b ility C pk A XQ Y AQ XY F 100 Cp QXY YX Q F H 5 4 3 2 1 * 8 .0 0 0 0 0 .4 4 7 1 3 4 0 .4 5 8 1 8 6 5 A QX Y A F F F H 7.0 4 A Q XY Fuj i 9 .9 7 6 6 S tD e v (W ith in ) S tD e v (O ve ra ll) 3 X Q Y G G Store B ran ds P ro c e s s C a p a b ility A n a ly s is fo r C 2 LSL 1 2 .0 0 0 0 LS L Me a n S a m p le N 2 QXY A A H How Much Kon ic a 1 A G H H H G G G F Organizational Difficulty Our C am era C o. Kon ic a Our C am era C o. Fuj i Store B ran ds H G G F G H 8.0 F F F 1 Q Y A X 0 G G 3 2 Q X Y A A QXY H G F P ro c e s s D a ta US L T a rg e t T a rg e t Intro to KPD&M, Copyright 2010, PDSS Inc. K F F Part Level P o te n tia l (W ith in ) C a p a b ility CPL J H F H O v e ra ll 100 0 .4 4 7 1 3 4 0 .4 5 8 1 8 6 C pk K F H W ith in * 8 .0 0 0 0 9 .9 7 6 6 S tD e v (W ith in ) S tD e v (O ve ra ll) Cp Similar to 35 K H H F US L P ro c e s s D a ta LS L Me a n S a m p le N I F H F Sub Assy Level 8 .0 1 5 .0 3 US L K 0 1 3 .0 4 T a rg e t K F H Relative Importance 12 P P M > US L P P M T o ta l 1 .4 4 Customer Assessment K Store B ran ds Our C am era C o. Weighted Importance E xp . "O ve ra ll" P e rfo rm a n c e P P M < LS L 1 .4 7 1 .4 4 P pk K F 3.0 I don't want it to look cheap K F 13.0 Prefer 35 mm format Has to be close to my 35mm in picture quality Has to take a minimum of 27 J 0 1 .4 7 O ve ra ll C a p a b ility Pp PPU PPL V V Ease of Use K F 10.0 Has to be light & easy to carry V W 5 Fuj i K m in. of 2 7 p ictu res Direction of Improvement H igh app earanc e ra tin g A X Q Y V iew find er A rea YX Q QXY A V iew find ing ind icat or g rap hics H G C am era w e ight A F G C arry ing me cha nis m H S nap force F L abe l cla rity G G G 35 mm film H H Su rfa ce roug hne ss H F 22 F Bo dy con tou ring C u sto m e r Im po rta nce H F Fl ash pow er F E xte rnal dim en sion s 2.0 F lash re -cha rge tim e 15.0 Relative Importance 1 .4 7 C pm V S W ind ing forc e Low purchase price Must fit in my shirt pocket Weighted Importance 1 .5 1 CPL V V General Features 1 .4 9 C pk V S S W Image Quality OTU Camera Example P o te n tia l (W ith in ) C a p a b ility Cp V V V S S W V V QXY A QXY Im pa ct f orce re sist anc e F U MC H F lash fo rce H Sn ap load res is tan c e F F D ens ity H C olor Satu ratio n F M axim ize pa rt re -us e F Co ntra s t 12.0 F Lo w G rain 4.0 Kon ica V V V A HOWs: Measurable Technical Requirements 5.0 How Much Te chn ica l A s se ssm en t V V V A QX Y A Q XY H W Pictures can't be "washed out" Can't mis-fire when I put it away in my pocket or purse Has to be durable if I drop it Organizational Difficulty Q Y A X V S S 1 F F W V S W S S 0 W F F 19 Sub System Level Similar to 35 I 29 W ith in K 22 S K 29 W W K 19 V W W Customer Assessment K 37 S S K 14 V S W US L P pk V V J 24 V K Go od Im a ge Qu ality V W K U niq ue F ea ture s W W F I Ea s y to us e W V F K W H A Ts for On e-Ti m e -U s e C am era (V O C Inp ut D ata ) S V V F I R egular 35 mm Ca mer a pe rform an c e V K 14 S S Ea s y to us e W W H A Ts for On e-Ti m e -U s e C am era (V O C Inp ut D ata ) V W V R egular 35 mm Ca mer a pe rform an c e S V W V U niq ue F ea ture s V 11.0 J 34 S S 16.0 K K Ease of Use 16 S Clear Pictures Low Graininess K D ens ity Go od Im a ge Qu ality S S V W 1 .5 1 1 .4 7 1 .4 7 C pm S General Features F lash re -cha rge tim e 27 . W 1 .4 9 CPU CPL C pk V V 33 57 19 13 14 17 28 78 . 36 29 29 29 V V P o te n tia l (W ith in ) C a p a b ility Cp V S S W HOWs: Measurable Technical Requirements Direction of Improvement 100 S tD e v (W ith in ) S tD e v (O ve ra ll) V V S W V V Image Quality OTU Camera Example * 8 .0 0 0 0 9 .9 7 6 6 V V S W 2 1 0 29 T a rg e t LS L V V W 3 Relative Importance P ro c e s s D a ta Me a n V V V 4 Weighted Importance P ro c e s s C a p a b ility A n a ly s is fo r C 2 LSL V V 5 Fuj i Store B ran ds Our C am era C o. W 1 2 .0 0 0 0 V S S S V V Organizational Difficulty W US L S QY How Much Y X Q A X QY Product Functional Capability P ro c e s s C a p a b ility A n a ly s is fo r C 2 LSL US L P ro c e s s D a ta Cp USL LSL US L 1 2 .0 0 0 0 T a rg e t W ith in * LS L 8 .0 0 0 0 Me a n 9 .9 7 6 6 S a m p le N O v e ra ll 100 S tD e v (W ith in ) 0 .4 4 7 1 3 4 S tD e v (O ve ra ll) 0 .4 5 8 1 8 6 P o te n tia l (W ith in ) C a p a b ility Cp 1 .4 9 CPU 1 .5 1 CPL 1 .4 7 C pk 6s 1 .4 7 C pm * O ve ra ll C a p a b ility 8 9 10 O b s e rve d P e rfo rm a n c e 11 12 E xp . "W ith in " P e rfo rm a n c e E xp . "O ve ra ll" P e rfo rm a n c e Pp 1 .4 6 P P M < LS L 0 .0 0 P P M < LS L 4 .9 2 P P M < LS L PPU 1 .4 7 P P M > US L 0 .0 0 P P M > US L 3 .0 2 P P M > US L PPL 1 .4 4 P P M T o ta l 0 .0 0 P P M T o ta l 7 .9 4 P P M T o ta l P pk 1 .4 4 8 .0 1 5 .0 3 1 3 .0 4 (USL-LSL): tolerance range for a KFR response within the product (Sys/SSys/SAys) (USL-LSL): as stated in the Reqts. Document 6s = six times the sample std. dev. of a Key Functional Response KFR in the design sKFR “s” measures functional variation “s” is composed of both mfg. and customer-base variation in product usage and environments Intro to KPD&M, Copyright 2010, PDSS Inc. 26 Part Specification Capability P ro c e s s C a p a b ility A n a ly s is fo r C 2 Cp USL LSL LSL US L P ro c e s s D a ta US L 1 2 .0 0 0 0 T a rg e t W ith in * LS L 8 .0 0 0 0 Me a n 9 .9 7 6 6 S a m p le N O v e ra ll 100 S tD e v (W ith in ) 0 .4 4 7 1 3 4 S tD e v (O ve ra ll) 0 .4 5 8 1 8 6 P o te n tia l (W ith in ) C a p a b ility 6s Cp 1 .4 9 CPU 1 .5 1 CPL 1 .4 7 C pk 1 .4 7 C pm * O ve ra ll C a p a b ility 8 9 10 O b s e rve d P e rfo rm a n c e 11 12 E xp . "W ith in " P e rfo rm a n c e E xp . "O ve ra ll" P e rfo rm a n c e Pp 1 .4 6 P P M < LS L 0 .0 0 P P M < LS L 4 .9 2 P P M < LS L PPU 1 .4 7 P P M > US L 0 .0 0 P P M > US L 3 .0 2 P P M > US L PPL 1 .4 4 P P M T o ta l 0 .0 0 P P M T o ta l 7 .9 4 P P M T o ta l 8 .0 1 5 .0 3 1 3 .0 4 (USL-LSL): tolerance range for a KTF spec. on a component / assembly P pk 1 .4 4 (USL-LSL): directly traceable to both Product & Manufacturing KFRs 6s = six times the sample std. dev. of a KTF Part specification sKTF “s” measures dimensional, surface finish, bulk material property or material variation “s” is composed only of unit-to-unit Part variation Intro to KPD&M, Copyright 2010, PDSS Inc. 27 Manufacturing Process Capability P ro c e s s C a p a b ility A n a ly s is fo r C 2 Cp USL LSL LSL US L P ro c e s s D a ta US L 1 2 .0 0 0 0 T a rg e t W ith in * LS L 8 .0 0 0 0 Me a n 9 .9 7 6 6 S a m p le N O v e ra ll 100 S tD e v (W ith in ) 0 .4 4 7 1 3 4 S tD e v (O ve ra ll) 0 .4 5 8 1 8 6 P o te n tia l (W ith in ) C a p a b ility 6s Cp 1 .4 9 CPU 1 .5 1 CPL 1 .4 7 C pk 1 .4 7 C pm * O ve ra ll C a p a b ility 8 9 10 O b s e rve d P e rfo rm a n c e 11 E xp . "W ith in " P e rfo rm a n c e 12 E xp . "O ve ra ll" P e rfo rm a n c e Pp 1 .4 6 P P M < LS L 0 .0 0 P P M < LS L 4 .9 2 P P M < LS L PPU 1 .4 7 P P M > US L 0 .0 0 P P M > US L 3 .0 2 P P M > US L PPL 1 .4 4 P P M T o ta l 0 .0 0 P P M T o ta l 7 .9 4 P P M T o ta l 8 .0 1 5 .0 3 1 3 .0 4 (USL-LSL): tolerance range for a KFR spec. on a production machine P pk 1 .4 4 (USL-LSL): directly traceable up to Part KTF Spec. 6s = six times the sample std. dev. of a KFR specification “s” measures Process functional variation sKFR “s” is composed only of functional mfg. variation Intro to KPD&M, Copyright 2010, PDSS Inc. 28 Required KP Mgt. Data for any form of Capability Assessment Gage R&R All KFRs, KPs or KTF Spec.s must have a capable metrology process documented & in use G a ge na m e : D a te o f s tudy: G a g e R & R (A N O V A ) fo r T h ic k n es s R e po rte d by: T o le ra nc e : M is c : C om p on en ts of V ariation B y P art 100 8 .3 % C o ntributio n P ercent % S tudy Va r 8 .2 % To le ra nc e 8 .1 50 8 .0 7 .9 0 G a ge R & R R e pe a t R e pro d P a rt P a rt-to -P a rt 1 2 3 S am p le R ang e R C h art b y O p erator F red 0 .2 Mary 5 6 7 8 9 10 8 .3 8 .2 UC L = 0 .1 4 5 9 0 .1 8 .1 R = 0 .0 5 6 6 7 0 .0 8 .0 LCL=0 7 .9 0 O p e ra to r F re d X b ar C h art b y O p erator J oe Joe M a ry O p erator*P art In terac tion Mary O p e ra to r 8 .2 8 .1 UC L = 8 .1 0 2 8 .0 L C L = 7 .9 8 6 A verag e F red 8 .2 S am p le M ean 4 B y O p erator J oe M e a n= 8 .0 4 4 7 .9 F re d Joe 8 .1 M a ry 8 .0 7 .9 0 P a rt 1 2 3 4 5 6 7 8 9 10 I & MR Chart U C L = 5 .9 1 7 5 0 M e a n = -0 .0 3 8 1 6 -5 L C L = -5 .9 9 4 S u b g ro u p 0 50 100 10 M o ving R a nge Each KFR, KP or KTF Spec. is placed under SPC so the Cp can be routinely quantified for Phase-by-Phase growth & Life Cycle stability characterization Individua l V a lue I and M R C hart for C 2 U C L = 7 .3 1 6 5 R = 2 .2 3 9 0 LC L= 0 Capability Study P ro c e s s C a p a b ility A n a ly s is fo r C 2 All KFRs typically have a target of Cp = 2 & Cpk of 1.5 Intro to KPD&M, Copyright 2010, PDSS Inc. LSL US L P ro c e s s D a ta US L 1 2 .0 0 0 0 T a rg e t W ith in * LS L 8 .0 0 0 0 Me a n 9 .9 7 6 6 S a m p le N O v e ra ll 100 S tD e v (W ith in ) 0 .4 4 7 1 3 4 S tD e v (O ve ra ll) 0 .4 5 8 1 8 6 P o te n tia l (W ith in ) C a p a b ility Cp 1 .4 9 CPU 1 .5 1 CPL 1 .4 7 C pk 1 .4 7 C pm * O ve ra ll C a p a b ility Pp 8 9 10 O b s e rve d P e rfo rm a n c e 1 .4 6 P P M < LS L 11 E xp . "W ith in " P e rfo rm a n c e 0 .0 0 P P M < LS L 4 .9 2 12 E xp . "O ve ra ll" P e rfo rm a n c e P P M < LS L PPU 1 .4 7 P P M > US L 0 .0 0 P P M > US L 3 .0 2 P P M > US L PPL 1 .4 4 P P M T o ta l 0 .0 0 P P M T o ta l 7 .9 4 P P M T o ta l P pk 1 .4 4 29 8 .0 1 5 .0 3 1 3 .0 4 KPD&M Flow-Down Map NUD VOC Need #1 System Reqt. Y=System KFR System Level Subsystem & Subassembly Level System Reqt. Y=System KFR System Reqt. Y=System KFR Subsystem-to-System Level Transfer Functions Y = f(x1, x2, …xn) Subsystem Reqt. Subsystem Reqt. Subsystem Reqt. Y1=SS KFR Y1=SS KFR Y1=SS KFR Subsystem Reqt. Subsystem Reqt. Subsystem Reqt. Y2=SS KFR Y2=SS KFR Y2=SS KFR Subsystem Reqt. Subsystem Reqt. Y3=SS KFR Y3=SS KFR Component Level Mfg. & Support Process Parameter Level NUD VOC Need #2 Subassy-to-Subsystem Level Transfer Functions: Y = f(x1, x2, … xn) Subassy. Reqt. Subassy. Reqt. Subassy. Reqt. X1=SAssy. KFR X1=SAssy. KFR X1=SAssy. KFR Subassy. Reqt. X2=SAssy. KFR Component Reqt.s Component Reqt.s Component Reqt.s Xn=Comp. KTF Spec.s Xn=Comp. KTF Spec.s Xn=Comp. KTF Spec.s Component Reqt.s Xn=Comp. KTF Spec.s Intro to KPD&M, Copyright 2010, PDSS Inc. Mfg. Process Reqt.s Mfg. Process Reqt.s Mfg. Process Reqt.s Xn=Mfg.. KTF Spec.s Xn=Mfg.. KTF Spec.s Xn=Mfg.. KTF Spec.s 30 Modeling & Simulation M&S was in place & was pretty good - but it left KP knowledge gaps - & not just a few!!! Could not predict physics-based interactions between controllable engineering parameters very well… Xi * Xj = ??? Could not predict physics-based interactions between controllable engineering parameters AND NOISE PARAMETERS = unwanted sources of variation… Xi * Noise = ??? • From variation in production parts, assembly & materials • From variation in disruptive sources external to the system • From variation in deteriorative sources internal to the system Weibull, Exponential, Gamma, Rayliegh, Lognormal, Normal, etc.???? Intro to KPD&M, Copyright 2010, PDSS Inc. 31 2 Major Matrices dominate the KP Dev. Process! On the Requirements Side: On the Parameters Side: The Houses of Quality from NUD-based QFD The Designed Experiment (DOE) Translated, Ranked, Prioritized & Allocated Key Customer Needs NUD Transfer Functions (Key Y = f(Xs)) measured, Ranked & Prioritized V V V V S S S W S V S S V S V V V V V V V V V S W S V V V S W W S S K K J K K K K K I K K J K K K W V I V S W S S V W W W W W S Pictures can't be "washed out" 5.0 Can't mis-fire when I put it away in my pocket or purse 4.0 Has to be durable if I drop it 12.0 Low purchase price 15.0 Must fit in my shirt pocket 2.0 Want to take pictures in any light 6.0 Has to be really easy to use 14.0 Easy to wind 1.0 F F F H F H A QXY W W W S V W F H H F A QXY 2.0 6.0 Has to be really easy to use 14.0 Easy to wind 1.0 Large view finder that helps me get pictures centered easily 10.0 Has to be light & easy to carry 13.0 m in. of 2 7 p ictu res H igh app earanc e ra tin g Fl ash pow er V iew find ing ind icat or g rap hics C am era w e ight C arry ing me cha nis m W ind ing forc e S nap force F lash re -cha rge tim e F lash fo rce Im pa ct f orce re sist anc e Bo dy con tou ring Sn ap load res is tan c e U MC C olor Satu ratio n E xte rnal dim en sion s D ens ity M axim ize pa rt re -us e C u sto m e r Im po rta nce Must fit in my shirt pocket Want to take pictures in any light K K K I F F F F Kon ic a Q X Y A Fuj i 0 1 Our C am era C o. Store B ran ds 2 3 H F F H H G H F G F F F F F H F G F G F A G H F H 5 F F F G G F H Factor A B C QXY G G G F F F H YX Q QXY G A H F F A X Q Y H H A Y Q A V S Prefer 35 mm format 8.0 H H H H 9.0 F F F F F F W Q A Y X S F F 3.0 H H F A S H G H F F F F F G F F A X G A X Q Y F 27 . V W H F F F F H F F F G H H G AQ XY S S S F G V A YX Q S W S V 10.0 Has to be light & easy to carry 13.0 Prefer 35 mm format 8.0 V S V W Large view finder that helps me get pictures centered easily S W G F G F G F F H AX Y Q W V S V V S V V W V W W W H H F F F F A H H H F F V W S V W W W W Q A Y X W Has to be close to my 35mm in picture quality V S X YQ S H S V W 9.0 F F F F F F V S K K K J K F F F F F F F H 33 57 22 19 22 29 19 37 14 19 13 14 17 28 24 14 34 78 . 36 16 XQ Y Go od Im a ge Qu ality F A V V C u sto m e r Im po rta nce 1 Relative Importance Direction of Improvement H V S V S V V General Features A XY Q Clear Pictures 16.0 Low Graininess 11.0 Pictures can't be "washed out" 5.0 Can't mis-fire when I put it away in my pocket or purse 4.0 Has to be durable if I drop it 12.0 Low purchase price 15.0 Must fit in my shirt pocket 2.0 Want to take pictures in any light 6.0 Has to be really easy to use 14.0 Easy to wind 1.0 Large view finder that helps me get pictures centered easily 10.0 J K K K K K I K K J K F F F F I 0 1 2 3 F H G F G F G A G G F F F H H F F F G G H F G F F H QXY H F F QXY G A H H F A F H F F F F F G -1 1 -1 -1 1 -1 1 1 -1 1 A Q A Y X 30 A F F Y X Q A X 1 20 -1 10 QY How Much V S S Sum of Squares epsilon2 %epsilon2 A 69.82 69.82/2233.39=0.031 3.1% B 401.70 401.70/2233.39=0.18 C 1620.35 1620.35/2233.39=0.72 72% AC 27.82 27.82/2233.39=0.012 1.2% AB 110.85 110.85/2233.39=0.05 5% Total 2233.39 Effect A XY Q F S W I don't want it to look cheap Organizational Difficulty 7.0 G H G H F F F F F G F F A X QY Q Y A X Kon ic a S V S S 5 V Fuj i 3 V V V V 2 V V V W 27 . V V V V S W S W Relative Importance V V V S S W V S V V HOWs: Measurable Technical Requirements 2.0 6.0 Has to be really easy to use 14.0 Easy to wind 1.0 Large view finder that helps me get pictures centered easily 10.0 Has to be light & easy to carry 13.0 F K K J K m in. of 2 7 p ictu res I F H igh app earanc e ra tin g C am era w e ight K C arry ing me cha nis m K L abe l cla rity K V iew find er A rea K V iew find ing ind icat or g rap hics K S nap force F lash fo rce F lash re -cha rge tim e J W ind ing forc e K 35 mm fi lm H F Su rfa ce roug hne ss E xte rnal dim en sion s F F F Bo dy con tou ring Im pa ct f orce re sist anc e Sn ap load res is tan c e U MC C olor Satu ratio n C u sto m e r Im po rta nce Must fit in my shirt pocket Want to take pictures in any light K F K F F K K I Q X Y A 0 Kon ica Our C am era C o. 1 2 3 F C G G F F F F F H F F F A G H F G G F F F G G H F G F F F H H F F G H H F F F F F F F Has to take a minimum of 27 3.0 I don't want it to look cheap 7.0 H H F F F F F G F A X Q Y A XQ Y AQ XY A YX Q F AX F H F H A G G H 9.0 G YX Q QXY H H 8.0 H H G G F Prefer 35 mm format Has to be close to my 35mm in picture quality G QXY A QXY H H F H A F H H 10 5 A Q XY H H F H 4 A QX Y F H -1 Fuj i Store B ran ds F F 22 V I F J F 19 S 15.0 22 V W 12.0 29 V S W W W 4.0 19 V W W 5.0 37 W V W S S 11.0 Has to be durable if I drop it Low purchase price 20 Similar to 35 14 W W W 16.0 Pictures can't be "washed out" Can't mis-fire when I put it away in my pocket or purse 24 S S V V Clear Pictures Low Graininess 14 W V V Ea s y to us e W V V W H A Ts for On e-Ti m e -U s e C am era (V O C Inp ut D ata ) S U niq ue F ea ture s V S V R egular 35 mm Ca mer a pe rform an c e 27 . 57 22 19 22 29 19 37 14 19 13 14 17 28 24 14 34 16 78 . 36 29 29 33 S S 34 W S V W 16 Go od Im a ge Qu ality V V S S V W K K D ens ity Direction of Improvement 2 1 Relative Importance I K K 3 0 Weighted Importance M axim ize pa rt re -us e 4 Co ntra s t OTU Camera Example 5 Fuj i Store B ran ds Lo w G rain Organizational Difficulty 1 Customer Assessment Ease of Use Fl ash pow er General Features Image Quality Our C am era C o. 30 V 33 57 22 19 22 29 19 37 14 19 13 14 17 28 24 14 78 . 34 16 36 29 29 29 B V V 1 0 Kon ic a A Y Q X YQ Q A Y X A XY Q F A F Y X Q A X QY How Much Te chn ica l A s se ssm en t Organizational Difficulty Q Y A X Kon ica 5 Fuj i 4 Store B ran ds Our C am era C o. 3 2 1 27 . 33 57 19 13 14 17 28 78 . 36 29 29 29 0 Weighted Importance Relative Importance Intro to KPD&M, Copyright 2010, PDSS Inc. 18% S 4 Store B ran ds Our C am era C o. Weighted Importance Te chn ica l A s se ssm en t 10 Y Q X YQ V Y X Q 15 In teraction P lot (d ata m ean s) for Y p lu s N oise A YX Q A V 3.0 20 A XQ Y AX F V Has to take a minimum of 27 How Much Q Y A X P 0.000 0.000 0.000 0.000 0.000 0.969 0.967 AQ XY G F F H MS F 69.82 196.14 401.70 1128.38 1620.35 4551.60 27.82 78.14 110.85 311.38 0.00 0.00 0.00 0.00 0.36 X Q Y A G F G SS 69.82 401.70 1620.35 27.82 110.85 0.00 0.00 2.85 2233.39 YX Q H H H H H G G F F F G A DF 1 1 1 1 1 1 1 8 15 A QXY H H F 5 A Q XY F H F H 4 A QX Y H H F H K Kon ic a Our C am era C o. Fuj i Store B ran ds F F F H K Q X Y A F F H 7.0 K H F H I don't want it to look cheap K H 8.0 3.0 I F 13.0 9.0 K Similar to 35 F F Has to be light & easy to carry Has to be close to my 35mm in picture quality I Customer Assessment Ease of Use F Prefer 35 mm format Has to take a minimum of 27 E xte rnal dim en sion s G G V V S W Sn ap load res is tan c e H G V S V V Image Quality OTU Camera Example C olor Satu ratio n F V V V QY 0 G F V V W G V W V V V Y X Q V 7.0 5 4 3 2 D ens ity Kon ic a Fuj i Store B ran ds Our C am era C o. Weighted Importance F Source A B C A*B A*C B*C A*B*C Error Total V V A XY Q V Has to take a minimum of 27 I don't want it to look cheap HOWs: Measurable Technical Requirements Q Y A X Co ntra s t A S S Has to be close to my 35mm in picture quality YX Q QXY Lo w G rain H Te chn ica l A s se ssm en t F S S Im pa ct f orce re sist anc e A G 25 V X YQ U MC G C Analysis of Variance for Y plus N A YX Q AX F M axim ize pa rt re -us e H H B AQ XY F W H A 30 XQ Y G G F Organizational Difficulty F 1 1 1 V H W H F Type Levels Values fixed 2 -1 fixed 2 -1 fixed 2 -1 V H How Much F M ain E ffects P lot - D ata M ean s for Y plu s N oise ANOVA: Y plus Noise versus A, B, C A QX Y A QXY H H A F F F A Q XY H H F 4 F F U niq ue F ea ture s V V V V W W J Ea s y to us e V W W V S S S K W H A Ts for On e-Ti m e -U s e C am era (V O C Inp ut D ata ) W W W W W K R egular 35 mm Ca mer a pe rform an c e V S V V W 29 V W A Q XY Similar to 35 I Te chn ica l A s se ssm en t S S V Ea s y to us e W V W H A Ts for On e-Ti m e -U s e C am era (V O C Inp ut D ata ) W V V R egular 35 mm Ca mer a pe rform an c e S U niq ue F ea ture s V S V A QX Y F S V V F K F 29 S S F K m in. of 2 7 p ictu res I K H igh app earanc e ra tin g K Customer Assessment K C am era w e ight I K C arry ing me cha nis m K F J L abe l cla rity F F K V iew find er A rea J F K V iew find ing ind icat or g rap hics K F F I S nap force K F V K F lash re -cha rge tim e K 15.0 F 29 S V W 11.0 12.0 F 29 Go od Im a ge Qu ality S S V W 16.0 Has to be durable if I drop it Low purchase price I W ind ing forc e S 4.0 K F lash fo rce S V W 5 5.0 Can't mis-fire when I put it away in my pocket or purse J 35 mm film 4 11.0 K Su rfa ce roug hne ss 3 16.0 K Bo dy con tou ring S V 2 U niq ue F ea ture s W 1 V Clear Pictures Low Graininess Pictures can't be "washed out" K Fl ash pow er S Ea s y to us e S V 0 V V V Ease of Use Y plus N o is e V V V Clear Pictures Low Graininess Go od Im a ge Qu ality Direction of Improvement Lo w G rain Fuj i Store B ran ds W H A Ts for On e-Ti m e -U s e C am era (V O C Inp ut D ata ) Direction of Improvement V W V S S General Features Co ntra s t OTU Camera Example Kon ic a Our C am era C o. R egular 35 mm Ca mer a pe rform an c e H igh app earanc e ra tin g m in. of 2 7 p ictu res C arry ing me cha nis m C am era w e ight V iew find ing ind icat or g rap hics L abe l cla rity V iew find er A rea Q X Y A S V Image Quality Similar to 35 35 mm film Bo dy con tou ring Fl ash pow er S nap force W ind ing forc e F lash re -cha rge tim e Su rfa ce roug hne ss E xte rnal dim en sion s F lash fo rce Im pa ct f orce re sist anc e U MC Sn ap load res is tan c e M axim ize pa rt re -us e C u sto m e r Im po rta nce D ens ity C olor Satu ratio n Lo w G rain Co ntra s t Customer Assessment Ease of Use W HOWs: Measurable Technical Requirements W V V S W V V OTU Camera Example V V V V V V General Features V V V W S HOWs: Measurable Technical Requirements Image Quality V V V V V V S S S V S S W Su rfa ce roug hne ss S W S S V S W V V L abe l cla rity W V V V V iew find er A rea V V 35 mm film V 32 Sequential Designed Experiments Process Concept Multi-vari Studies Screening DOEs Design Optimize Verify Tolerance Balancing DOEs System Stress Test DOEs Modeling DOEs Optimization DOEs Robust Design DOEs Building your knowledge of statistically significant Key Parameters using a sequential DOE strategy 33 DOE choices in Product Commercialization There are 7 major types of Designed Experiments 1. Multi-vari studies - (correlation & hypothesis forming studies) 2. Screening Experiments - (sorting controllable factors & noise factors for significance) 3. Modeling Experiments - (quantifying Y = f(x) relationships) 4. Mean Optimization Experiments “Everything should be as simple as possible – but not simpler…” - (adjust mean performance to hit a desired target) 5. Robustness-to-Noise Experiments - (reduce s in the presence of noise) 6. System Stress Testing Experiments - (identify sensitivity across interfaces & system boundaries) 7. Tolerance Balancing Experiments - (refine cost vs. quality in subsystems, subassemblies & parts) 34 Identifying Key Functional Response & Key Adjustment Parameter Relationships Key Functional Response Ideal (KFR) Key Adjustment Parameter (KAP) Intro to KPD&M, Copyright 2010, PDSS Inc. 35 Key Functional Robustness Parameters: KAPs & KFRPs: How they affect a KFR - Robust & Tunable Performance! KFRPs are KFR Variance Reducers Robust against Variation Intro to KPD&M, Copyright 2010, PDSS Inc. KAPs are KFR Mean Shifters Mean Adjusted to VOC Target 36 Reliability Development Process Concept Design Optimize Verify Reliability Requirements Definition -System Reliability Modeling – Probabilistic Simulations -Subsystem / Subassembly - Component Reliability Development Tasks - FMEAs, CAE/CARD, DOE, Robust Design, Tolerance Design Reliability Assessment Tasks -Life Tests, Accelerated Life Tests -HALT, HASS, HAST, Destructive Tests 37 Design for “X” Process Design Concept Optimize DfX Requirements -System (Product & Production Processes) -Subsystem / Subassembly - Component / Materials Design for X Tasks - Benchmarking, DFMA, Design for Cost, VA/VE… DfX Assessment Tasks -HSER DOEs & Related Tests 38 Verify KPD enhanced Team Performance Score Cards Preventive Peer Reviews DFSS Tool: Quality of Tool Use Data Integrity Results vs. Reqts Avg. Score Data Summary incl. Type & Units Task Requirement Contingent Design Reviews Phase Task: Avg. Tool Score % Task Fulfillment Task Result vs. Del. Reqts Red Yellow Green Deliverable Requirements Reactive Gate Reviews Gate Deliverables Grand Avg. Tool Score Summary of Tasks’ Completion Summary of Tasks Results vs. Del. Reqt. Red Yellow Green Gatekeeper Comments Measuring the use of tools, completion of tasks and the fulfillment of Gate Deliverable requirements… 39 Gate Deliverable Scoring linkage from Tool & Task Scorecards DFSS Tool: Quality of Tool Use Data Integrity Results vs. Reqts Avg. Score Data Summary incl. Type & Units Task Requirement Quality of Tool Use Phase Task: Avg. Tool Score % Task Fulfillment Task Result vs. Del. Reqts Red Yellow Green Grand Avg. Tool Score Summary of Tasks’ Completion Summary of Tasks Results vs. Del. Reqt. Red Yellow Green % Task Fulfillment Task Scoring Items Task Results vs. Gate Reqts Corrective Action & Due Date Comments on Risk Confidence in Data Score 40 Tool Results vs. Task Reqts Deliverable Requirements Avg. Tool Score Gate Deliverables Data Integrity Tool Scoring Items Gate Deliverable Scoring Items Risk Accrual against Gate Reqts. Summary – building KP Dev. capability & maturity Companies who have deployed KPD&M are slowly realizing they can’t use it right if they don’t have SE functional excellence & governance in their Phase-Gate process… With KPD&M integrated into SE the results are much better Ad hoc systems work in product commercialization processes keeps you from being great… Formal SE Process & Roles Ad hoc SE 41 KP enhanced SE Process, Roles, tooltask-deliverables… The ARDEC Story: Defining a process for Pro-active KPD&M What approaches are available for conducting KP Development & Management? Are the steps during Development different from those conducted when defining KPs after Launch? Technology & Product Development? Post-launch Production & Ongoing Life cycle Management out to Discontinuance? Intro to KPD&M, Copyright 2010, PDSS Inc. 42 A New Technology & Product Development Process was constructed: Vector Similar to the definition of a Vector, the ARDEC T&PDP will serve as a course or compass direction for navigating ARDEC IPTs through technology and product development projects doing the right things at the right time. Webster - Vector: a quantity that has magnitude and direction and that is commonly represented by a directed line segment whose length represents the magnitude and whose orientation in space represents the direction; b: a course or compass direction c: a course to be taken by an aircraft. ARDEC ‘s Technology & Product Development Process (T&PDP) = Vector Intro to KPD&M, Copyright 2010, PDSS Inc. 43 Foundations of Vector Vector is built upon a wide variety of benchmarks that were “value-mined”… 8 major Corporations: Ford 6 texts from product development consulting firms: NASA / DoD TRL models Latest version of the DoD 5000.2 Intro to KPD&M, Copyright 2010, PDSS Inc. 44 Best elements integrated to design the T&PDP process…. Benchmarks VOC NUD Reqts. Benchmarks, Hybridization and Pugh Concept Selection Process used to document Value Selection - led to the design of Vector Block Diagrams Entrance Criteria & Assumptions Major Activities Deliverables Readiness Tasks Results Exit Criteria Objectives Completeness Intent Enabling Best Practices Enablers Intro to KPD&M, Copyright 2010, PDSS Inc. 45 Block Diagrams: Defining What to do…. 1. Entrance Criteria 3. Major Activities 5. Deliverables Readiness Tasks Results 6. Exit Criteria 2. Objectives Completeness Intent 4. Enabling Best Practices Enablers Intro to KPD&M, Copyright 2010, PDSS Inc. 46 And when to do it…. The Vector Process is constructed of Blocks of Major Activities.. Entrance Criteria & Assumptions Major Activities Deliverables Readiness Tasks Results Block of Major Activities Exit Criteria Completeness Objectives Intent Enabling Best Practices Enablers Vector Technology Dev. Process… 9 Blocks of Major Activity Groups defined & documented: TD1 TD2 TD3 TD4 TD5 TD6 TD7 TD8 TD9 Vector EMD Process… 10 Blocks of Major Activity Groups defined & documented: EMD1 EMD2 EMD3 Intro to KPD&M, Copyright 2010, PDSS Inc. EMD4 EMD5 EMD6 EMD7 EMD8 EMD9 47 EMD10 Each Block contains a designed Work Flow… adaptable to the type of Project Block of Major Activities Activity 4 Activity 2 Activity 5 Activity 1 Activity 3 Block of Major Activities Block of Major Activities Activity 6 Activity 4 Activity 2 Block of Major Activities Activity 5 Activity 1 Activity 3 Activity 4 Activity 6 Activity 2 Block of Major Activities Activity 5 Activity 1 Activity 3 Activity 6 Activity 4 Activity 2 Activity 5 Activity 1 Activity 3 Activity 6 Activity 4 Activity 2 Activity 5 Activity 1 Activity 3 Activity 6 MS Project Network Diagrams will illustrate serial / parallel flow paths of Major Activities within each Block… Including linkage between the Actions & their enabling Tool sets. Intro to KPD&M, Copyright 2010, PDSS Inc. 48 Aligning the Blocks to TRLs & MRLs – Vector added KP depth-of rigor & clarity of the TRL / MRL definitions & detailed deliverables A Materiel Solution Analysis B TECHNOLOGY DEVELOPMENT Engineering & Manufacturing Development Materiel Development Decision TD3-4 IOC C PRODUCTION & DEPLOYMENT TD 7 TD 8 TRLs 1-3 TRL 4 TRL 5 TRL 6 TRL 7 TRL 8 TRL 9 Analytical/ Experimental Critical Function/ Characteristic Proof of Concept Component And/or Breadboard Validation In a Laboratory Environment Component And/or Breadboard Validation In a Relevant Environment System/ Subsystem Model or Prototype Demonstrated In a Relevant Environment System Prototype Demonstrated In an Operational Environment Actual System Completed Qualified Through Test and Demonstration Actual System “Mission Proven” Through Successful Operations MRLs 1-3 MRL 4 MRL 9 MRL 10 Manufacturing Cost Drivers Identified TD3-4 TD5 Intro to KPD&M, Copyright 2010, PDSS Inc. MRL 5 Capability to Produce Prototype Components Cost Model Constructed TD6-7 MRL 6 OPERATIONS & SUPPORT FRP Decision Review Post CDR Assessment TD5-6 Manufacturing Capability to produce Feasibility Technology In Lab Assessed. Environment. Concepts Manufacturing Risks defined/ Identified developed FOC EMD 10 MRL 7 Capability to Capability to Produce Produce System/ Systems, Subsystems Subsystem Or Components in a Prototypes Production Representative Environment MRL 8 Pilot Line Capability Demonstrated. Ready for LRIP Detailed Cost Analysis Complete Cost Model Updated To System Level Unit Cost Reduction Efforts Underway Engineering Cost Model Validated TD 8 EMD 9 EMD 10 Low Rate Full Rate Production Production Demonstrated. Demonstrated. Capability In Lean Production Place for FRP Practices In Place LRIP Cost Goals Met Learning Curve Validated EMD 10 FRP Unit Cost Goals Met 49 Technology Dev. Phases & Gates were defined from the 9 TD Block Diagrams…. Phase 2: Technology Concept Dev. Phase 1: Technology Project Plan & Requirements Dev. Tech Dev. Project Definition & Plan 1 Tech Reqts Dev 2 Tech Concept Dev 3 Phase 3: Technology Sub-level Dev. & Optimization Subsys Tech Prototype & measmnt System Design & Dev 5 Tech Prototype perf Stability & Tunability Dev 6 Intro to KPD&M, Copyright 2010, PDSS Inc. Tech Robustness Dev (Dynamic) 7 Tech Functional & Analytical M&S 4 Phase 4: Technology Integration & Final Optimization Tech System Integration, Nominal & Stress Testing 8 Tech Transfer 9 50 Product Dev. Phases & Gates were defined from the 10 EMD Block Diagrams…. Phase 1: Product Project Plan & Requirements Dev. EMD Program definition and plan 1 Technical reqmnts Definition, documentation, and prioritization 2 Phase 2: Product Concept Development Product & production process Concept development and selection, system architecture 3 Phase 3: Product Sub-level Dev. & Optimization Subsys design testing and capability perf characterization 6 Subsys design robustness testing, optimization, DOEs under stress 7 Preliminary Subsys concepts, modeling, simulations, virtual designs 4 Subsys design and prototyping, test planning and measmnt systems capability readiness 5 Phase 5: Product & Mfg. Process Verification & Validation System Integration, nominal & stress testing, desensitization 8 Final Product Design 9 Product design verification / Mfg Process verification and validation 10 Phase 4: Product System Integration & Optimization Intro to KPD&M, Copyright 2010, PDSS Inc. 51 Example of Vector Technology Development Process Swim lanes loaded with major KPD&M Tasks Vector Swimlanes with KPD&M Process & Enabling DFLSS TMBPs by TD Phase Swimlanes TD Phase 1 TD Phase 2 TD Phase 3 Gather & Define KEY (NUD) Customer Needs Systems Engineering Design Engineering Gather & Define KEY (NUD) Customer Needs Translate, rank & prioritize KEY (NUD) System Level Technical Reqts Define Key System Level Functional Responses (Ys) Define System KFR Target Values & Tolerances Develop & Load KPM data base Develop Capable System Level Measurement Systems Translate, & allocate KEY (NUD) Sub Level Technical Reqts Define Key Sub Level Functional Responses (Ys) Define Sub Level KFR Target Values & Tolerances Develop ID candidate Capable Sub Sub Level KAPs Level & KFRPs Measurement Systems TD Phase 4 ID candidate System Level KAPs & KFRPs ID System Define KP Design Level System Flow- System Level Noise down Tree KP Maps Development DOEs & Verification Test Plans Conduct System Level Nominal Performance experiments Conduct System Level Robustness Performance experiments Conduct System Level Performance Balancing experiments Document System Level KPM Data base ID Sub Level Noise Diagrams Define Sub Level KP Flowdown Trees Conduct Sub Level Modeling experiments Conduct Sub Level Robustness experiments Conduct Sub Level Tolerance Balancing experiments Document Sub Level KPM Data base Conduct Sub Level Robustness experiments Conduct Sub Level Tolerance Balancing experiments Document Sub Level KPM Data base Design Sub Level KP Development DOEs & Verification Test Plans Conduct Sub Level Screening experiments Develop Capable System & Sub Level Measurement Systems Quality Engineering & Systems Assurance Logistics Gather & Define KEY (NUD) Customer LOG Needs Project Management Assure all KPD&M tasks are properly selected, resourced & realistically scheduled Translate, & allocate KEY (NUD) Sub Level Technical LOG Reqts Assure the KPD&M Process is up to date & documented KPD&M, in theCopyright PAL Define Key Sub Level Functional Responses (Ys) Define Sub Level KFR Target Values & Tolerances Develop ID Candidate Capable Sub Sub Level KAPs Level & KFRPs Measurement Systems Define & Conduct System & Sub Level KP Verification Tests ID Sub Level Noise Diagrams Define Sub Level KP Flowdown Trees Design Sub Level DOEs & Verification Test Plans Conduct Sub Level Screening experiments Conduct Sub Level Modeling experiments Process Assurance Intro to 2010, PDSS Inc. 52 Transfer KP Data base to Production & Supply Chain 11 General Steps in KPD after you are in Production – if you did NOT do KPD during Technology or Product Development… KPD&M Process Step Enabling Tools & Methods Step 1: Create a KPD&M Project Charter Project Planning & Mgt., Monte Carlo Sim., Cost Estimation, SMART reqts. & goal ID, Intro to KPD&M Module Step 2: Create a cross-functional team of experts to help ID a thorough set of KPs Specific, in-depth experience; Technical expertise & judgment, DFLSS training, JIT training & mentoring in KP tool sets Step 3: Generate / Assess requirement clarity, classification & flow-down Customer/Stakeholder ID, Interviewing Methods, KJ Analysis, NUD vs. ECO classification, Kano Analysis, QFD & HOQs, Doors, Relational data base Step 4: Generate I-O-C-Diagrams, PDiagrams, Noise & Boundary Diagrams I-O-C Diagramming, P-Diagm’g, Noise Diagm’g, System Noise Mapping, Boundary & Interface Diagm’g, 1st Principles Modeling & Simulation Step 5: Structure a Key Parameter Flowdown Tree & Relational Data base Functional Diagm’g, Flow Diagm’g, Cockpit SW, KP Data base dev., KP Scorecards, KP Reqts. & Measured Y worksheets Step 6: ID unique sub-areas of focus; lean out, rank & prioritize the areas to work on NUD vs. ECO classification, Kano Analysis, Pareto process, QFD ranking, Function Trees & Flow Diagm’g., Noise Diagm’g, FMEAs Step 7: Prove measurement systems are capable Measurement Systems Analysis, Gage R&R Studies Step 8: Design & conduct experiments on candidate Key Parameters & Noises Hypothesis formation, SPC & Cp/Cpk studies, DOEs, t-Tests, ALT, HALT, HAST, Duane Plotting Step 9: Analyze data using ANOVA & other statistical methods to ID sensitivities & Cpk ANOVA, Descriptive & Inferential Statistical methods, Regression Analysis, Correlation Analysis, Confidence Intervals, Main effects & interaction plotting Step 10: Establish & verify tolerance ranges & % contribution to variation of Key Ys Screening DOEs, ANOVA, Taguchi’s Loss Function, Additive Variance Modeling, SPC & Cp/Cpk Studies, F Ratios Step 11: Create a Mfg. & Production implementation & control plan for KPs Control Planning, SPC & Cp/Cpk Studies, KP documentation, KP relational data base & Score cards Summary of KPD&M Concepts REQUIREMENT FLOWDOWN & ALLOCATION CAPABILITY FLOW-UP of Cp & Cpk SYSTEM KFR PERFORMANCE SYSTEM REQUIREMENTS SUBSYSTEM KFR PERFORMANCE SUBSYSTEM REQUIREMENTS SUBASSY. KFR PERFORMANCE SUBASSEMBLY REQUIREMENTS COMPONENT REQUIREMENTS MFG. PROCESS REQUIREMENTS TRANSFER FUNCTION LINKAGE IS USED TO TRACK KEY RELATIONSIPS & TRANSMISSION OF VARIATION…. COMPONENT KTF PERFORMANCE MFG. PROCESS KFR PERFORMANCE Why do we take the time to do it properly? Problem Prevention. Intro to KPD&M, Copyright 2010, PDSS Inc. 54