Viral Inactivation Unit

Virus inactivation involves dismantling a virus’s ability to infect cells without actually eliminating the virus.

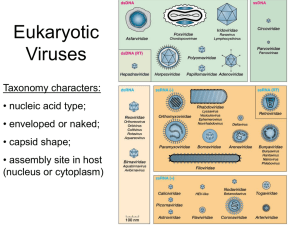

Viruses can be lipid-coated or nonenveloped.

Virus inactivation works by one of the following two mechanisms:

By attacking the viral envelope or capsid and destroying its ability to infect or interact with cells.

By disrupting the viral DNA or RNA and preventing replication.

FDA specifies that a clearance of at least 3 logs must be achieved for mAb production.

Solvent/Detergent (S/D) Inactivation

• Effective with lipid-coated viruses

• Disrupts the interactions between molecules in the lipid coat , rendering the coat dysfunctional and impeding replication

• Commonly used and has a reliable safety record

• Chemicals need to be removed downstream

Pasteurization/Heat

• Effective with non-lipid and lipid-coated viruses

• Typically in a liquid at 60 o C for 10 hours

• Protein product must have a higher thermal resistance than the virus

• Requires the addition of stabilizers, which will need to be removed downstream

Low pH Treatment

• Most effective with lipid-coated viruses

• Acidic conditions deactivate virus

• Protein product must have a higher resistance to low pH conditions than that of the viral particles

• No additional clearance steps are needed downstream

Virus Inactivation Tank

Storage Tank and Diafiltration

Ion Exchange Chromatography

Stream

S-042

S-045

S-110

S-046

Mass Flow Rate

(kg/batch)

763.2967

0.153

0.905

763.449

Component

Acetic acid

Impurities mAb

WFI

Polysorbate 80

WFI

Nitrogen

Oxygen

Acetic acid

Impurities mAb

Polysorbate 80

WFI

Mass Composition

(%)

0.0784

0.1064

3.2681

96.5470

50.0000

50.0000

76.7118

23.2882

0.0784

0.1064

3.2675

0.0100

96.5377

Connection

From storage tank

Chemical inlet

Vent to atmosphere

To polishing filter

There was no way to measure concentrations of active and inactive viruses

Manipulating temperature, holding time, and flow rates had very little effect in our simulated unit

Theoretically, a longer holding time and a higher S/D concentration should results in higher levels of inactivation

The volume increased minimally as the detergent concentration increased

SuperPro® Specification for

Polysorbate80 at 0.01% wt

Volume

Max Allowable

Working Volume

Height/Diameter Ratio

Height

Diameter

Design Pressure

Value

852.88 L

90 %

3

2.138 m

0.713 m

1.52 bar

Supplier

Used

Range of Cost

For Tank with agitator

Machinery and Equipment

Company, Inc.

$12,500.00

Aaron Equipment Company $8,500.00 - $10,000.00

Cost for

Mixing Unit

New

Cost for Tank without agitator

Total Cost of

Tank and Agitator

$25,000.00 - $100,000.00

$128,500.00

Slimline Manufacturing

Pope Scientific Inc.

$1,000.00

$127,500.00

$11,000.00

Apache Stainless Equipment

Corporation

$15,000.00

$20,000.00

$35,000.00

Simulation Unit Operation:

In Place Steaming Transfer In Pull In Holding Transfer Out In Place Cleaning

Operating conditions

Steam: normal pressure, 42.5 kg/batch

Polysorbate 80: 0.0765 kg/batch

Operating Costs

Steam (per batch)

Polysorbate 80 (per batch)

Usage Rate (per equipment-hr)

Labour Hours (labour hrs/hr)

Cost

$0.18

$2.32

$2,088.00

8

TOTAL $2,090.50 + 8 Labour Hours

Develop a way to simulate active and inactive virus concentrations

›

Optimize for temperature, holding time, and S/D concentration

Polysorbate 80 concentration of 0.01-1.0 wt%

Purchase a used blending tank from Aaron

Equipment Company for $8000