Fermentation

advertisement

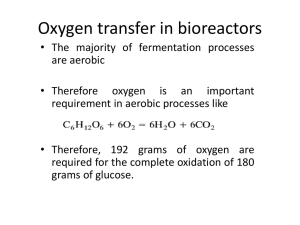

Production Of Enzymes By Fermentation Method What is fermentation? • Pasteur’s definition: “life without air”, anaerobe redox reactions in organisms. • New definition: a form of metabolism in which the end products could be further oxidized. For example: a yeast cell obtains 2 molecules of ATP per molecule of glucose when it ferments it to ethanol. What is fermentation? Microorganisms, typically grown on a large scale, to produce valuable commercial products or to carry out important chemical transformations. This process is commonly referred to as Fermentation. Types of fermentation process • There are two methods of fermentation used to produce enzymes. 1. submerged fermentation 2. solid-state fermentation. Submerged fermentation/ Solid-state fermentation • Submerged fermentation involves the production of enzymes by microorganisms (e.g. bacteria, yeast) in a liquid nutrient media (water content of the media: > 95%) • Solid-state fermentation is the cultivation of microorganisms on a solid substrate. • Carbon containing compounds in or on the substrate are broken down by the micro organisms, which produce the enzymes either intra-cellularly or extra-cellularly. Submerged fermentation/ Solid-state fermentation Cont…. • The enzymes are recovered by methods such as centrifugation, for extra cellularly produced enzymes and lysing of cells for intracellular enzymes. • Many industries are dependent on enzymes for the production of their goods. • Industries that use enzymes generated by fermentation are the brewing, wine making, baking and cheese making. Submerged Fermentation Cont… • • • • Advantages: Measure of process parameters is easier than with solid-state fermentation. Bacterial and yeast cells are evenly distributed throughout the medium. There is a high water content which is ideal for bacteria. Disadvantages: High costs due to the expensive media. 2. Solid State Fermentation - Solid-state fermentation (SSF) is another method used for the production of enzymes. - In solid state, water content is 40~ 80%. - Solid-state fermentation involves the cultivation of microorganisms on a solid substrate, such as rice husk, wheat bran, sugar beet pulp, wheat and corn flour. Solid State Fermentation Cont… Advantages: SSF has many advantages over submerged fermentation. These include: 1. High volumetric productivity 2. Relatively high concentration of product 3. Less effluent generated 4. Simple fermentation equipment. Fermentation • Aerobic • Anaerobic Aerobic fermentation • Adequate aeration. • Bioreactors- adequate supply of sterile air. • In addition, these fermentors may have a mechanism for stirring and mixing of the medium and cells . eg. Antibiotics, enzymes, vitamins. Anaerobic fermentation • In anaerobic fermentation, a provision for aeration is usually not needed. e.g. Lactic acid, ethanol, wine • When referring to fermentation regarding food, there are no distinctions between anaerobic and aerobic metabolism. Cont…. • Fermentation changes the characteristics of the food by the action of the enzymes produced by bacteria, mould and yeasts, which can occur in aerobic or anaerobic conditions Cont…. • The process of fermentation requires a food source (e.g. glucose); enzymes form bacteria or yeast and (depending on the product) anaerobic or aerobic conditions. Cont.. • Of all the microbial products manufactured commercially, antibiotics are the most important. • Antibiotics are chemical substances produced by microorganisms to kill other microorganisms. • They are used in the treatment of infectious diseases. RANGES OF FERMENTATION PROCESS • Microbial cell (Biomass) ….Yeast • Microbial enzymes ….Glucose isomerase • Microbial metabolites ….Penicillin • Food products ….Cheese, yoghurt, vinegar • Vitamins ….B12, riboflavin • Transformation reactions ….Steroid biotransformation Fermenter • The heart of the fermentation process is the fermentor. In general: • Stirred vessel, H/D 3 • Volume 1-1000 m3 (80 % filled) • Biomass up to 100 kg dry weight/m3 • Product 10 mg/l –200 g/l Types of fermentor • • • • • • Simple fermentors (batch and continuous) Fed batch fermentor Air-lift or bubble fermentor Cyclone column fermentor Tower fermentor Other more advanced systems, etc The size is few liters (laboratory use) - >500 m3 (industrial applications) View looking down into a 125m3 stainless steel fermentor Cross section of a fermenter for Penicillin production Cross section of a fermenter for Penicillin production Fermentation could be: • Batch mode • Fed batch mode (continuous) Batch fermentation • Most fermentations are batch processes • Nutrients and the inoculum are added to the sterile fermentor and left to get on with it! • Anti-foaming agent may be added. • Once the desired amount of product is present in the fermentor the contents are drained off and the product is extracted. • After emptying, the tank is cleaned & prepared for a new batch. Continuous fermentation • Some products are made by a continuous culture system. • Sterile medium is added to the fermentation with a balancing withdrawal of broth for product extraction. Fermentation Medium Definition of medium nutritional, hormonal, and substrate requirement of cells • In most cases, the medium is independent of bioreactor design and process parameters • the Type of medium: complex and synthetic medium (mineral medium) • Even small modifications in the medium could change cell line stability, product quality, yield, operational parameters, and downstream processing. Medium Composition Fermentation medium consists of: • Macronutrients : (C, H, N, S, P, Mg sources water, sugars, lipid, amino acids, salt minerals) • Micronutrients: (trace elements/ metals, vitamins) • Additional factors: growth factors, attachment proteins, transport proteins, etc) • For aerobic culture, oxygen is sparged Inoculums • Incoculum is the substance/ cell culture that is introduced to the medium. The cell then grow in the medium, conducting metabolisms. • Inoculum is prepared for the inoculation before the fermentation starts. • It needs to be optimized for better performance: • Adaptation in the medium • Mutation (DNA recombinant, radiation, chemical addition) Required value generation in fermentors as a function of size and productivity Microbial rates of consumption or production C, N, P, S source H2O H + biomass CO2 O2 product heat Microbes Overview of bioreactors for submerged system - Classification: operation modes: 1. batch: stirred tank 2. continuous: chemostat, fluidized-bed 3. modified types of the above modes: fed-batch, chemostat with recycle, multi-stage continuous reactors Oxygen supply: - aerobic: airlift - anaerobic Form of biocatalyst: free cell (enzyme) immobilized cell (enzyme) packed-bed, membrane reactor Industrial Bioreactor World's Largest Industrial Fermenter (Chem. Eng. News,10-Apr-78) The fermenter is 200' high and 25 ft diam The End