FERMENTATION

advertisement

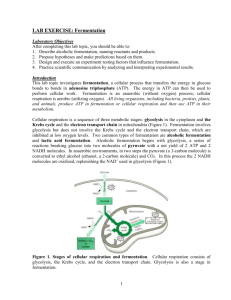

FERMENTATION May 2014 FERMENTATION DEFINED Fermentation is the process in which microorganisms convert organic compounds into a simpler compounds. These organisms are typically yeast and bacteria which ferment sugar thus creating beer, wine, bread, kimchi, yogurt and other foods. The by-products of beer/wort fermentation are carbon dioxide, alcohol and various flavor compounds. CHOOSING YOUR YEAST What Kind of beer do you want to make? Lager Yeast: (Saccharomyces pastorianus) Bottom fermenting, slower fermentation at a temperature low enough that the yeast cells can sink. Typically 45-55*F Ale Yeast: (Saccharomyces cerevisiae) Top fermenting, more aggressive fermentation at a temperature high enough to carry the yeast cells to the top of the fermenting liquid. Typically 60 -72*F Try experimenting with different yeasts and fermentation temperatures. Some yeasts will accentuate or mute malt and hop character. OPTIMIZING FERMENTATION Having enough yeast: Doing a proper starter for the volume/gravity of the beer you are making. Nutrients: Having enough yeast nutrients and oxygen necessary for healthy fermentation. Proper temperature control: Every yeast has a sweet spot where they function best. www.whitelabs.com and www.wyeast.com FERMENTATION CONTAINERS Glass Carboys Clarity allows you to gauge the activity of the fermentation. Two sizes commonly available, a 6 1/2 gallon and 5 gallon Because they are clear, carboys must be shielded from light Food grade plastic buckets Less expensive than glass and safer to handle. Option of having spigots, which makes siphoning unnecessary Spigots allow for easier bottling. Easier to add fruit and other adjuncts . T YPICAL HOMEBREW FERMENTERS Buckets: $15 Glass Carboys: $30-40 AIRLOCK VS. BLOW-OFF TUBE VS. FOIL Airlock is appropriate when there is adequate amount of head space . A blow-off hose is appropriate when fermentation is vigorous and there is less headspace, allows foam and hop remnants to be carried out of the fermenter. Tinfoil can be used over carboy top WHERE TO FERMENT? A place with a stable temperature within the appropriate temperature range for the yeast being used. Ales 60 -72*F, Lagers 45-55*F Closets, basements, or a spare bathroom. Fermentation chamber or refrigerator. Shield from direct sunlight for two reasons. sunlight will cause a photochemical reaction with the hop compounds and skunk your beer. PRIMARY FERMENTATION Active fermentation should start within 12 o 24 hours. The three important factors for a successful fermentation are 1) pitching enough yeast, 2) good wort nutrients, and 3) maintaining a consistent temperature in the correct range. It is not uncommon for an ale's primary fermentation to be done 2-3 days. Lagers take longer because of the cooler temperatures, 7 -21 days. SECONDARY FERMENTATION Single stage: No transfer to secondary, wait 10 -14 days to condition the beer and allow clearing, then proceed to packaging. Two stage fermentation: Longer conditioning time, gets beer off majority of yeast, and may aid in clarification. A good place to add fruit or other adjuncts. TEMPERATURE AND FLAVOR Lager yeast produce less fruity esters than ale yeasts but can produce more sulfur compounds during primary fermentation. Many first time lager brewers are astonished by the rotten egg smell coming from their fermenters, sometimes letting it convince them that the batch is infected and causing them to dump it. Don't do it! Fortunately, these compounds continue to vent during the conditioning (lagering) phase and the chemical precursors of other odious compounds are gradually eaten up by the yeast. A previously rank smelling beer that is properly lagered will be sulfur-free and delicious at bottling TEMPERATURE CONTROL TOOLS Brew Belt/heater: $30 Thermostat $57 HIGH TECH HOME FERMENTATION LOW TECH HOME FERMENTATION