Gasoline Vapor Recovery - Dr.Hassan S. Ghaziaskar

advertisement

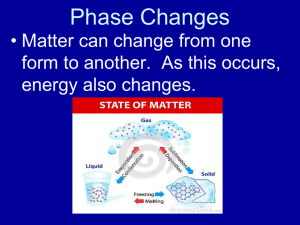

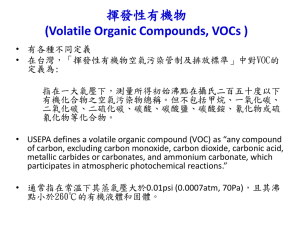

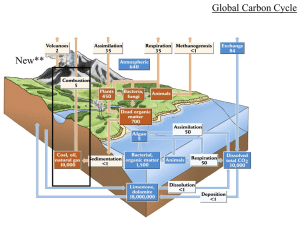

An Evaluation of Evaporative Emissions of Gasoline from Storage Sites and Service Stations By: J.S. Razavizadeh Supervisor: Prof. H.S. Ghaziaskar Tuesday 88.02.22 , 11.00 am Displacement emissions 1- Introduction Breathing and withdrawal emissions 2- Evaporative emissions Filling emissions Emission from vehicle refueling Emissions prevention and minimization 3- Factors affecting evaporation Collection of vapor absorption 4-control of emissions Vapor recovery Pressure swing and purge regeneration Condensation Diffusion technologies Treatment of vapor 5-Legislation regarding evaporative emissions •The hydrocarbons emitted during petrol storage and distribution can be broadly classified as volatile organic compounds (VOCs) 1-Pure hydrocarbons VOCs 2-Partially oxidized hydrocarbons 3-Organics containing chlorine , sulphur and nitrogen 1-Industrial and domestic solvents(40%) 2-exhaust gases from motor vehicles(25%) 3-Evaporation and loses from motor vehicle(10%) VOCs emissions originate from 4-Petrol distribution(3%) 5-Vehicle refueling(2%) 6-Oil refining (3%) 7- from other source(17%) Oxygen Molecule (O2) + NOx + VOC + Sunlight Ozone Molecule (O3) Typical petrol distribution Products storage At refinery Rail car Pipe line Marine vessel Bulk storage at Marketing depot Road tanker Storage tank at service station Motor vehicle Typical petrol vapor composition (only VOC) COMPUND VOLUME Ethane Traces Propane 1.5% Isobutane 8% n-Butane 10% Pentane 14% Benzene 5000ppm Hexane and others TOTAL (voc only, remainder in air) 6% 40% EVAPORATIVE EMISSIONS the average emission from a typical European petrol storage and distribution system, is O.56% volume of the petrol distributed displacement refueling breathing and withdrawal 0.3 0.03 filling 0.05 0.18 Displacement emissions • Displacement emissions occur from fixed roof storage facilities (bulk storage tanks), as well as underground service station tanks due to vapor displacement by incoming petrol. • Displacement emissions from fixed roof storage facilities account for 0,14 % • from service station storage tanks for 0,16 % Breathing and withdrawal emissions • Breathing emissions are caused by variations in tank contents, temperature and by changes in barometric pressures that cause expansion and contraction of the liquid and vapor in a tank. • Withdrawal emissions occur when petrol is pumped out of a storage tank resulting in the intake of air through pressure/vacuum relief valves or vents • Breathing and withdrawal emissions from bulk storage tanks account for 0,02% and from service station storage tanks for 0,01% of total emission losses. Filling emissions • Filling emissions occur when petrol is transferred from storage tanks to road tankers. • two types of vapor making up filling emissions, namely preloading vapor (PLV) and evolution vapor (Ve). • PLV is residual vapor originating from a tank's previous contents, being displaced by loading of the new product, and is defined as a fraction or percentage of full saturation, Cp,. • Cp less than 1 % (Cp < 0,Ol) when the previous contents of a road tanker were a nonvolatile product. • Cp between 10% and 20% (0,l < Cp < 0,2) when the previous contents of a tanker were discharged completely at one point. • Cp between 30% and 50% (0,3 < Cp < 0,5) when the previous contents were discharged at several occasions. • Cp between 90% and 100% (0,9 < Cp < 1,O) when the contents of a tanker were discharged at a service station tank that allows for vapor return. • Evolution vapour (ve) evaporates from the product itself when it is being loaded. Petrol can be loaded into a road tanker via top splash loading, submerged top loading or bottom loading. • In order to estimate Ve a parameter VB is used to represent the amount of splashing in a tanker during filling. • VB is equal to the fraction of the original tank atmosphere that is assumed to be completely saturated during loading. 1. 2. 3. VB = 0,4 for top splash loading. VB = 0,15 for submerged top loading. VB = 0,13 for bottom loading. Concentration of petrol vapor under equilibrium conditions filling emission liquid to vapor volume equivalence factor Average preloading vapor concentration Parameter representing the amount of splashing Emissions from vehicle refueling •These emissions contribute to 0,18 volume % of the total emissions from petrol storage and distribution systems 1- product (liquid petrol) properties. FACTORS AFFECTING EVAPORATION 2- Liquid/vapor interface areas. 3- turbulence in the relevant liquid and vapor. Control of emission • • • • • • • Safe operation Ease of operation Reliable operation Low maintenance Low operation costs Low investment costs Highest possible emission reduction. Emissions prevention and minimization Collection of vapor absorption 4-control of emissions Vapor recovery Pressure swing and purge regeneration Condensation Diffusion technologies Treatment of vapor Emission prevention and minimisatim • • • • decreasing the volatility of petrol vapor balancing minimizing the liquid/vapour interface area reducing turbulence. Typical construction of a modern day tanker Tanker at Terminal (No Vapor Recovery) Tanker at Service Station (No Vapor Recovery) Bottom Loading at Terminal (With Vapor Recovery) Fuel Drop at Service Station (With Vapor Recovery) API to Drop Hose Connection (At Service Station) Vapour recovery Step 1 collection of VOCs/air mixture Step 2 separation of VOCs from air Step 3 the recovery of the separated VOCs into liquid state. Once the vapor has been collected, various processes or combinations of processes can be used to separate and recover the vapor. These include condensation, absorption, diffusion and adsorption. Condensation: by compression or cooling Condensation is most efficient for VOC recovery at relatively high VOC concentration (above 5000 ppm) Air VOC/air mixture Step1 collection Step2 and 3 Separation and Recovery via condensation Flow diagram for condensation as vapor recovery process. Condensed VOCs Advantage and disadvantage of condensation Advantage Disadvantage Moderate efficiencies, 50-90% Energy requirements of Mechanical refrigeration are high Simple, flexible, safe process Can handle wide range of products Nitrogen source needed for cryogenic condensation May result in the generation of a wastewater stream Absorption : absorbed in to liquid due to molecular force. depends of vapor pressure and the temperature of the absorbent. Low boiling point hydrocarbon liquid( like crude oil or kerosene) are often used for VOC separation from air via absorption. air VOC /air mixture Step1 collection Step2 Separation from Air via absorption (with kerosene) Recycling of Absorbent (kerosene) Absorbent (petrol)/VOC mixture Step3 Recovery via Absorption (with petrol) Absorbent (kerosene)/ VOC mixture Separation from Absorbent via distillation VOC • Absorption can be used for high vapor flows and VOC concentration ranging between 500 ppm to 5000 ppm. Advantage and disadvantage of absorption Advantage Good for high humidity streams (relative humidity < 50%) High efficiencies, 95_98% Wide range of vapor flow rates and VOC concentration Disadvantage Liquid absorbent may be transferred to the exit gas Diffusion technologies: such as membrane is relatively new Two types of membrane namely diffusion membrane and solubility membrane. air VOC /air mixture Step1 collection Step2 Separation via diffusion Step3 Recovery via absorption Step3 Recovery via condensation VOC /absorbent mixture Condensed VOCs Advantage and disadvantage of diffusion technology Advantage Disadvantage Recovery of between 95 and 99% Constant vapor flow rate are Necessary, but buffer tanks are a major safety concern Safe process and operational flexibility High power consumption Very wide range of products handling, for example ,hydrogen, Sulphide , acetone , MTBA, ethyl acetate Post treatment system needed in The case of very high emission standards. Adsorption: most effective methods and most economical. the adsorption medium most generally used is activated carbon and hydrophobic zeolites. two regeneration technologies are currently in use, namely: thermal regeneration and pressure swing and purge regeneration. air VOC /air mixture Step1 collection Step2 Separation via adsorption Step3 Recovery via absorption Step3 Recovery via condensation VOC /absorbent mixture Condensed VOCs Advantages and disadvantages of adsorption advantages Wide range of vapor and vapor concentration can be handled . disadvantages Hydrogen sulphide from crude oil vapor poison the carbon. Efficient, relatively simple process organic compounds like ketones, aldehydes and organic acids can causes localised hot spots or bedfires in carbon beds. Flexible and inexpensive to operate Light hydrocarbon fraction such as methane are very poorly adsorbed Carbon performance decreases with high humidity vapor streams (ralative humidity <50%) 1. References: 2. MEMBRANES FOR VAPOR/GAS SEPARATION Richard W. Baker Membrane Technology and Research, Inc. 1360 Willow Road, Suite 103, Menlo Park, CA 94025 3. NEW TECHNOLOGY FOR EMISSION REDUCTION AT PETROL STATIONS OHLROGGE K., WIND J. GKSS-Forschungszentrum Geesthacht GmbH, Institut für Chemie, Max-Planck-Strasse, D21502 Geesthacht, Germany 4. Safety design of a petrol pump attendant robot Francesco Becchi, Rezia M. Molfino and Roberto P. Razzoli University of Genova, Genova, Italy 5. The Problem of Volatile Organic Compound (VOC) Emissionsfrom Petrol in Lithuania and Methodological Aspects of Emission Reduction Viktoras Doroševas, Vitalijus Volkovas, Ramūnas Gulbinas Technological Systems Diagostics Institute, Kaunas University of Technology 6. Membrane Based Vapor Recovery at Petrol Stations Klaus Ohlrogge and Jan Wind 7. A policy instrument for the reduction of greenhouse gas emissions An Interim Report to the Tyndall Centre for Climate Change Research 7th |January 2004 Dr Kevin Anderson, Tyndall North, UMIST Kevin.anderson@umist.ac.uk Tel. 0161 200 3715 Dr Richard Starkey, Tyndall North, UMIST Questions?