Machine design 2

advertisement

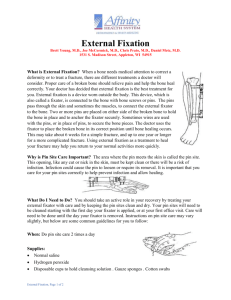

Machine design 2 Joints 1 loads • • • • mechanical forces, moments… thermal chemical changing in place/ time … static cyclic dynamic 2 materials • metals – ferrous/ non~ • cast iron • steel – carbon/ alloy • plastics • ceramics • composite • • • • • • • • • density conductivity … elasticity plasticity ductility brittleness toughness (impact) creep 3 loads & stresses Stress distribution uniforn/linear (Mohr, H-M-H) 4 general purpose machine elements static elements • joints • frames • springs (mechanical) drive systems • bearings • shafts • couplings & clutches • drives vessel systems • pipes • valves • tanks • (technical fluids) 5 function of joints: join elements together:) • Kinematic –allowing special freedoms of movement • Fixing or orientating no movement at all 6 Joint types 1. • permanent – – – – – – welded soldered brazed glued riveted … • detachable (fasteners) – bolted – pin/ cotter pin/ spline –… semi-detachable: press fitted 7 melting Tm welding base material melts not melts pressing hot 100°C brazing glueing cold 450°C soldering permanent mech. joints detachable w/wo parts © bagyinszky 8 Joint types 2. • joining by: force shape material 9 Joint types 2. • joining shaft & hub by: force friction shape positive, no-slip material we/ so /gl 10 hybrids Split/ groowed pin bolt 11 Keys & pins square par. flat ~ tapered Gib-head round Woodruff pin roll-pin keyseat/ keyway 12 keyways - stresses milling cutters shearing crushing 13 sliding, stress concentration splined shaft poligon evolvent/ kerb-splines 14 shaft-hub joints by friction press fit conic rings clamp + locknut fit by other means… roll pin taper groowed pin other fasteners 1 loads: bending shearing contact strs. double shear pin/ bolt „bearing” stress p = F/vd crushing other fasteners 2 (threaded joints next time…) pin: fastening, locating (elastic) retaining rings cotter pin 18 welding same material (cohesive forces) melting and/or pressing weldeability (rigidness, oxidation) heat sources: flame, arc, current, beam… MIG, RSW… butt weld filler material corner weld (fillet seam) spot welding 19 strength calculations • useful length / thickness (faults) allowable stress: σa = Reh φ /n φ factor of weakening 0,5~0,9 n safety factor 20 design rules for welding 21 welding – pros & cons • (almost) the same strength • no pretreatment • non-series, repair • can be automated • …. • • • • residual stresses oxidation hidden failures …. 22 molten filler metal soldering brazing T < 450 °C lead, tin, zinc… • T > 450 °C silver, brass… 0.05 -0.2 mm adhesive forces less strength 23 surface pretreatment rivets shearing rupture of plates crushing solid tubular, blind 24 adhesive bonding (glueing) physical bond: solvent, contact, hot-melt… chemical bond: hardening polymers (epoxy resins…) 25 adhesives – pros & cons • • • • quick, easy no heat insulates repairs • • • • pretreatment limited strength limited temps …. honeycomb structure 26 Thank you for kindly attention! 27