View Company Presentation

advertisement

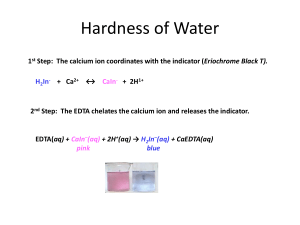

AVA Chemicals P. Ltd At Glance Brief Introduction Company Management Awards & Certification • Dominant Market presence – Over 27 years • 3 manufacturing units • Pioneers in chelate chemistry in India • Family owned professionally run company ensuring faster decision making • Management Team has In-depth technical knowledge of Chelates and Fine Chemicals • Expertise in key areas of Business • Current operations now spearheaded by second generation - Professionally qualified with over 20 years experience in International Marketing • • • • ISO 9001:2008 CRISIL rated D&B Certified 2nd Prize CHEMEXCIL - 2008 (SME Category) 3 manufacturing units located at Badlapur MIDC, Thane District, Maharashtra. Present capacity is on double shift basis and can be scaled up on need basis. Can commit large part of the spare capacity (chelating agents) Open to expanding capacity for dedicated customers based on committed orders Particulars Installed Capacity (MTs p.a) Chelated Salts Fine (MTs p.a) Chemicals (MTs p.a) TOTAL 10000 7500 2500 Year Event 1985 Started with manufacture of EDTA & its derivatives 1990 Expanded product range to include other chelating agents like DTPA, NTA etc 1994 Started making HEDP derivatives 1995 Setup facilities for manufacturing fine chemicals 1998 Started manufacture of custom made specialty products for a large multinational pharma company. 2000 Added phosphates, Sulphates etc to its Fine Chemicals segment 2005 Introduced EP/ LR / AR / GR grades of Chelates and Fine Chemicals. 2006 Achieved ISO 9001:2008 certification 2008 Started manufacture of Citrates & Fe-EDDHA 2009 First round of expansion at Unit I 2010 Received 2nd highest export award by CHEMEXCIL in SME category 2011 Capacity expansion at Unit III 2012 Capacity expansion at Unit II Leading supplier of over 70 products meeting diverse requirements of industries like: Soap and Detergents Pharmaceuticals / Lab Reagents Agrochemicals Water Treatment / Textile Chemicals Coatings / Electroplating Food Ingredients Paper and pulp Polymers Leather processing Industrial cleaning General Industrial Application Oilfield chemicals and many more EDTA Series EDTA Pure Acid Disodium EDTA Trisodium EDTA Tetra Sodium EDTA (powder) Tetra Sodium EDTA (liquid) DTPA Series DTPA Pure Acid DTPA Na5 DTPA Potassium Hydroxide (K5DTPA) NTA Series NTA Pure Acid Trisodium NTA (powder) Trisodium NTA (liquid) HEDP Series HEDP 2Na (Etidronate Disodium) HEDP 4Na (Etidronate Tetrasodium) HEDP 60% (Etidronic Acid) Undesirable metal ions are often present in water. Chelating agents deactivate the metal ions thereby acting as builders. Ammonium Acetate Barium Acetate Calcium Acetate Magnesium Acetate Manganese Acetate Potassium Acetate Sodium Acetate Anhydrous / Trihydrate Zinc Acetate Mono Ammonium Phosphate Di Ammonium Phosphate Trisodium Phosphate Ammonium Sulphate Magnesium Sulphate Zinc Sulphate Mono / Hepta Sodium Carbonate Anhydrous / Mono Citric Acid Mono / Anhydrous Mono Potassium Phosphate Mono Sodium Phosphate Ammonium Formate Sodium Citrate Trihydrate EDTA Disodium EDTA Tetrasodium EDTA Tripotassium Fine Chemicals find application in pharmaceutical industry mostly as excipients, API’s or buffer solutions, starting raw material. EDTA Series Calcium EDTA Cobalt EDTA Copper EDTA Dipotassium EDTA Ferric Ammonium EDTA Ferric Sodium EDTA Magnesium EDTA Manganese EDTA Zinc Ammonium EDTA Zinc Disodium EDTA Zinc Potassium EDTA DTPA Series Copper DTPA Ferric DTPA Manganese DTPA Zinc DTPA Ferric Ammonium DTPA Others Combi Mixtures Fe-EDDHA Humic Acid Every crop needs several types of nutrients. Chelated metals act as a carrier for micro nutrients. These are applied directly or into the soil or in foliar sprays. They are sometimes referred as advance fertilizers. Also used in Floriculture / Horticulture HEDP Series HEDP -175 HEDP - 230 HEDP - 270 HEDP - 330 HEDP - 400 (HEDP 50%) HEDP - 500 (HEDP 60%) HEDP - 600 HEDP - Potassium (HEDP Kx) ATMP Series ATMP Acid ATMP Tetrasodium ATMP Pentasodium ATMP Potassium (ATMP Kx) PBTC DETPMP Phosphates MAP DAP TSP Sodium Carbonate Ammonium Sulphate BKC 50% / 80% Water Treatment Chemicals, Cleaning Chemicals, Water Cleaning Chemicals, Industrial Cleaning Chemicals, Cooling Water Cleaning Chemicals, Boiler Water Treatment Chemicals EDTA Series EDTA Disodium EDTA Tetrasodium (P) EDTA Tetrasodium (L) DTPA Series DTPA Acid DTPA Pentasodium (L) DTPA Pentapotassium (L) HEDP Series HEDP Disodium (HEDP - 230) HEDP Disodium (HEDP - 270) HEDP - 400 (HEDP 50%) HEDP - 500 (HEDP 60%) NTA Series NTA Acid NTA Trisodium (P) NTA Trisodium (L) Calcium Acetate Ammonium Acetate Sodium Acetate Trihydrate Sodium Acetate Anhydrous Mono Ammonium Phosphate Di Ammonium Phosphate Tri Sodium Citrate Mono Sodium Phosphate Di Sodium Phosphate Tri Sodium Phosphate EDTA Calcium EDTA Disodium EDTA Ferric Sodium Zinc Sulphate Monohydrate Sodium Bicarbonate Exports to over 28 countries till date. Our regular exports are to : 1. Australia 2. Argentina 3. Bangladesh 4. Bangkok 5. Belgium 6. Canada 7. Dubai 8. France 9. Germany 10. Indonesia 11. Iran 12. Israel 13. Japan 14. Korea 15. Malaysia 16. New Zealand 17. Netherlands 18. Pakistan 19. Portugal 20. South America 21. Singapore 22. South Africa 23. Syria 24. Sri Lanka 25. Spain 26. Turkey 27. UK 28. Vietnam 12 Besides our existing products, we have:• Created In-house technical know how to manufacture over 200 additional Inorganic Fine Chemicals. • Developed special capabilities in “Custom manufacturing” of Inorganic Fine Chemicals. In either case, we sign Memorandum of Understanding (MOUs), Confidentiality Disclosure Agreements (CDA’s) / Customer Protection Guarantee (CPG’s) etc, which is a standard practice. Some of our existing relationships for custom manufacturing include the following: • US based Pharmaceutical Company • France based Pharmaceutical Company • Germany based Coatings & Metal Treatment Company • India based Rubber Polymer Company • Middle East based Oil & Gas Company • UK based Agrochemicals Company Equipment: • • • • • • • Reactors ranging from 2 KL to 10 KL Capacity Centrifuges Crystallizers Pulverizers Sieving Machine Sparkler Filter Fluidized Bed Dryers Reactions that can be carried out: • • • • • • • • • • • • • Acetylating Oxidation Addition Alkylation Dehydration Halogenation Amination Reduction Esterification Substitution Displacement Polymerization Isomerization • Adequate, spacious, well equipped and maintained facilities are available for producing fine chemicals, intermediates or finished products on contract / toll basis. • Facilities capable of carrying out multiple stage production processes including reactions, chemical synthesis, blending, crystallization, filtration and other related processes. Capacity - Present capacity is on double shift basis and can be scaled up on need basis. Large part of the spare capacity can be committed for contract / toll manufacturing. Strategic Location - Manufacturing facilities located at Badlapur MIDC, a chemical industrial zone: • 30 kilometers from Nhava Sheva - India's leading and most advance seaport. • 25 kilometers from Bhiwandi – central hub of transport companies. Logistics - Availability of good CHAs. Long standing relationship with leading shipping lines, freight carriers etc ensure timely deliveries and good logistics support. Packing - We offer choice of packaging to our QC/QA – Independent in-house laboratory equipped with Atomic Absorption Spectrophotometer (AAS) and other equipments. Well experienced and technically qualified persons ensuring process control. ETP – Arrangement with local Common Effluent Treatment Plant (CETP) for waste & effluent management. Certification & Recognition - ISO 9001:2008, CRISIL (SME1), Plant audited by leading Indian & MNC customers Thank you for your patience and time

![[MIn - ]/[HIn 2](http://s2.studylib.net/store/data/005622090_1-a61ecc244fc4a127a11c4475c40f111e-300x300.png)