Galvanic Cells - INTRODUCTION

advertisement

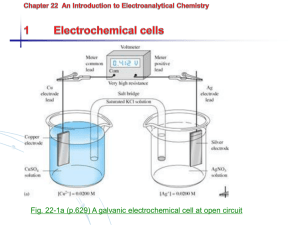

Galvanic Cells - INTRODUCTION • Energy sources • How did the battery business start? • History of batteries makes history of electric energy Galvanic Cell As ELECTROCHEMICAL DEVICE : Electrode reactions Thermodynamics and kinetics Properties of Materials WUT - MESC - Galvanic Cells II As ENERGY SOURCE : Position on energy market Power supply Technology & Economy 1 Electrical power generation • Fuel – combustion – heat effect – mechanical energy – generating electricity CHEMICAL ENERGY indirectly into ELECTRICAL • Renewable energy source ( wind, water, geothermal) – transformation of work to electric energy • Galvanic, fuel, fotovoltaic cells CHEMICAL ENERGY directly into ELECTRICAL WUT - MESC - Galvanic Cells II 2 DIFFERENT CELLS • galvanic cells – primary and secondary Chemical substances in electrodes Expressed as Q • Electrode Reactions Expressed as U Energy = U . Q Fuel cells Stream of reagents ISOLATED Electrode Reactions Expressed as U Energy = U . Q PORTABLE/TRANSPORTABLE INDEPENDENT FORM ELECTROENERGETICAL NETWORK WUT - MESC - Galvanic Cells II 3 Some milestones in history 1780 L. Galvani – „animal electricity” 1800 A. Volta – pile (battery of zinc and silver discs, separated by cloth wet with salty solution) 1866 G. Leclanche – zinc – MnO2 cathode battery 1859 G. Plante’ – lead acid accu made of Pb plates, 1881 – Faury et al – pasted plates instead of solid Pb WUT - MESC - Galvanic Cells II 4 Transformation from isolated current sources to electrical network • Electromagnetic induction – discovered by Faraday about 1840 • Electromechanical generator – Siemens about 1857 • T. A . Edison : electric bulb 1879, lighting system in NY, Ni-Fe accumulator • DC contra AC – Edison contra Westinghouse, first big power plant in America – Niagara Falls – advantages of supplying energy with AC WUT - MESC - Galvanic Cells II 5 Electrical circuits with batteries • Management of voltage and current – connecting the batteries • Ohm’s law in simple DC circuit : external resistance (load),internal resistance( ohmic drop on battery components), polarisation resistance (ohmic drop on reaction) E = I ( Rinter + Rpol + Rload) • Energy and power Energy = Q ∙U = I ∙ t ∙ U = (m / k) ∙U Power = energy produced/consumed in time unit WUT - MESC - Galvanic Cells II 6 Electrode potential • • • • φ= φo + RT/nF ln ( aMe / aMe(n+) ) Standard potential at unit activity of particles - φo + deviation from standard due to non-unit activity (concentration) Can not be measured directly Electrode reaction • • Transport of charge or charge and mass over phase boundary electrode – electrolyte Phases : electrode = fragment of condensed phase electronically conductive electrolyte = ionically conducting „space” Observed effects of electrode reaction : • • Change of oxidation grade of an atom in a molecule / ion in solution Accompanying changes : creation / decomposition of a phase changes in phase structures WUT - MESC - Galvanic Cells II 7 Anodic reaction Ared →Box + n e- Cathodic reaction Cox + n e- →Dred Overall cell reaction A+B=C+D Potential φox Potential φred With E = Δ φ Electromotoric force E comes from change in free enthaply of the overall reaction, Also combining the ΔG with electrical equivalent of energy E = -ΔG /nF And defining Eo = ΔG o/nF for standard conditions we get Nernst equation : E = Eo – RT / nF ln K where K – equilibrium constant of reaction ABCD WUT - MESC - Galvanic Cells II 8 Signs + / - in cells - convention More negative potential on left side : Zn = Zn2+ + 2e : Cu = Cu2+ + 2e Less negative to the right φ = - 0.76 V φ = 0.34 V formal scheme for the cell External connection / Zn / Zn SO4 aq // CuSO4 aq / Cu / external connection Sign - // sign + But ..... WUT - MESC - Galvanic Cells II 9 Structure and functions of electrodes A/ metallic reactive electrodes (deposition-dissolution, formation of compounds on the surface) Reagent and current collector(two-in-one) Charge and mass transport – on the surface B/ inert electrodes metalls, graphite, semiconductors Current collector, not a redox reagent Charge and mass transport – on the surface C/ multi-function, multi-component electrodes electroactive component (often insulator) electronically conducting matrix other additives with special functions Charge and mass transport – on triple-contact sites Redox active Cond. matrix electrolyte WUT - MESC - Galvanic Cells II 10 Various types of batteries WUT - MESC - Galvanic Cells II 11 Specyfic energy - Energy density WUT - MESC - Galvanic Cells II 12 Typical battery application WUT - MESC - Galvanic Cells II 13 WUT - MESC - Galvanic Cells II 14 Zn/MnO2 Cells • Leclanche type – electrolytes lightly acidic or neutral: anodic reaction – product: Zn salts soluble in the electrolyte ( NH4Cl, NH4OH, ZnCl2 → complexes of Zn with OH- and Cl- • Alkaline – electrolyte: concentrated KOH: anodic reaction – product: solid ZnO – the composition ot the electrolyte does not change • Different anodic mechanism → different yields of the cells : in alkaline cells the maximum current density is higher WUT - MESC - Galvanic Cells II 15 Zn electrode and redox cycling • Solid Zn anode : Zn – 2e-→ Zn2+ in solution + 2e- → Zn as powder, needles (→ due to specyiic features of electrocrystallization of metals) Volumen of anode ↑ electrical contact within the anode ↓ • Powder Zn anode : Zn – 2e- → ZnO ( in OH-solution) + 2e- → Zn as powder discharge (work) charge • Zn metallurgical foil - 100% material as energy • complex structure (Zn + conducting matrix + glue) - part of electrode „useless” as energy source WUT - MESC - Galvanic Cells II 16 MnO2 cathode • MnIVO2 + H2O ↔ MnIIIO(OH) + OH(other compounds of MnIII possible) • OH- ion takes part in the anodic reaction – formation of Zn complexes • At higher load (high current density) possible limitation of anode kinetics due to low concentration of comlexing ions • Valid for Leclanche type ( Zn complex salts soluble in the electrolyte) WUT - MESC - Galvanic Cells II 17 Cells with Zn anode Cell name Cathode Electrolyte Daniell Cu → Cu2+ ZnSO4/CuSO4 1.2 Leclanche MnO2→MnO(OH) (→Mn3O4 possible) NH4Cl, ZnCl2 1.6 Alkali MnO2→MnO(OH) KOH 1.55 Zinc-air O2 → O2- (on carbon matrix) KOH 1.45 Zinc-silver Ag2O → Ag KOH 1.6 WUT - MESC - Galvanic Cells II OCV or EMF (V) Anode product – soluble Zn salts Anode product - ZnO 18 Zn - air • • A : Zn → Zn2+ (as ZnO) + 4eC : O2 + 2 H2O + 4e- → 4 OH- • • • • Cathode reaction on inert catalytic electrode ( graphite + catalyst + binder) Oxygen supply forced by underpressure in cathode space Slow kinetics of oxygen electrode – main limitation for current value Parasitic processes : Zn + O2 OH- + CO2 loss of water WUT - MESC - Galvanic Cells II EMF = 1.65 V 19 Electric vehicles • • • • • „zero-emission” buses and vans on tests in USA and Germany Repleceable anodic casette of Zn with KOH (gelled) Ca. 200 Wh/kg and 90 W/kg at 80% d.o.c. Supercapacitor in hybrid system to boost accelaration External regeneration of anodes WUT - MESC - Galvanic Cells II 20 Zn/MnO2 cells WUT - MESC - Galvanic Cells II 21 Zn/MnO2 cells WUT - MESC - Galvanic Cells II 22 How to get „more” from a single cell? • • Redox potential for Me – Men+ couples Zn-Zn2+ -0.76 V O2-OH- 0.4 V Mg-Mg2+ -2.36 V Ag+-Ag 0.8 V Na-Na2+ -2.92 V MnO2-MnO(OH) app. 0.74 V Li-Li+ -3.05 V F2 – 2F- 2.87 V Apply special conditions of discharge Reserve cells one-time discharge • Eliminate water from cells non-aqueous solutions synthesis in inert atmosphere WUT - MESC - Galvanic Cells II 23 Reserve (activated) cells inactive electrolyte : -closed in a vessel -solid salt to be molten • Separated elements – • Signal to make contact electrolyte – electrodes : closing the circuit inside the cell • Activation on signal (decision) or by event (water flow, emergency) • No or poor activity if energy demand intermittent • Very long storage time (no parasitic reactions and self-discharge) • Energy supply – short time, but high current densities dry electrodes WUT - MESC - Galvanic Cells II 24 Reserve cells - examples • Mg + 2 H2O Mg anode reactions Mg(OH)2 + 2H+ + 2e (Mg covered with MgO layer, proton recombinates with OH from cathode space) Mg(OH)2 + H2 Mg open to water, no contribution to current drawned from the cell • Both reactions take place, H2 evolution wastes part of electrode, but • Gas bubbling → intensive stirring → quick transport → high current WUT - MESC - Galvanic Cells II 25 Reserve cells – examples cont. • Cathodes in Mg cells : • 2 AgCl + 2e → Ag + 2 Cl• 2 CuCl + 2e → Cu + 2 Cl• other simple salts : PbCl2 , CuSCN, Cu2I2 • Overall reaction : Mg + PbCl2 = MgCl2 + Pb • Electrolytes : sea-water, simple salts specific for best cathode rate • construction: composite cathodes, mechanical separation of electrodes, soakable separators for electrolyte WUT - MESC - Galvanic Cells II 26 Water and gas activated batteries - applications •Air-sea rescue systems •Sono and other buoys •Lifeboat equipment •Diverse signals and alarms •Oceanographic and meteo eq. •And many others, including military WUT - MESC - Galvanic Cells II 27 Molten salts and thermal batteries Main parts of a thermal battery Anodes : Li alloys : Li(20)Al, Li(40)Si (melt higher than Li – 181 and 600/7090C resp.) Cathodes : Ca, K, Pb chromates, Cu, Fe, Co sulfides, V2O5, WO3 Electrolyte: molten LiCl-KCl eutectic 3520C Combination with bromides Thermal dissociation KCl = K+ + Cl-, high conductivities, simple reaction mechanism WUT - MESC - Galvanic Cells II 28 Thermal batteries – applications • Pyrotechnic heat source – squib, burned serves as inter-cell conductor • Insulation – ceramic, glass, polymers – depends on time of discharge (salt must be kept molten !) • Voltages – single OCV : 1.6 V (Li/FeS2) , to ca. 3 V (Ca/K2Cr2O7) • Activated life-time : minutes, in special constructions hours • Energy density : 2 – 35 Wh/kg • • High currents possible Applications – mainly military WUT - MESC - Galvanic Cells II 29 Solid electrolyte cell Na-S Anode Na → Na+ Cathode xS → Sx2- , x 3~5 Overall 2Na + xS → Na2Sx OCV = 2.07 V Temperature 310 – 350oC sulphur Tmelt = 118, boil= 444oC β-alumina Na2O∙11Al2O3 , conducts Na ions σ300 C ca 0.5-0.1 S/cm WUT - MESC - Galvanic Cells II 30 Solid electrolyte cell Na-S • • • • Can be used as rechargeable cell Applications : stationary energy storage, motive power Working with high-temperature cells: warm-up on start keep warm at intervals in operation manage excessive heat during operation (ohmic and reaction) Construction of stacks : electrical and heat management Insulated enclosure Heat distribution Cooling system Electrical networking WUT - MESC - Galvanic Cells II heaters 31 Stationary energy storage Na-S system WUT - MESC - Galvanic Cells II 32 Lithium – iodine solid electrolyte cell • • Anode : Cathode : • Overall : • LiI • • Li → Li+ + 2e nI2∙P2VP + 2e → (n-1)I2P2VP + 2 I- (poly-2-vinylpyridine) 2Li + I2 → 2 LiI thin layer on contact between Li and cathode, ionically conducting OCV ca 2.8 V Discharge rates 1 – 2 μA/cm2 (very low) WUT - MESC - Galvanic Cells II 33 Primary and secondary cells - basic PRIMARY SECUNDARY Irreversible use of electrodes Recovery of electrodes – by supplying electrical energy we restore electrode oxidation state and structure Anodic and cathodic process (redox) related to specified electrodes, run only once Anodic and cathodic reactions repeat on both electrodes in chargedischarge cycles Solid metal electrodes (one-way) Products may be soluble Substrates and products stay in electrode phase Redox reaction „all-solid state” Minimalizing changes in electrode structure and shape WUT - MESC - Galvanic Cells II 34 Secondary cells - basic • • • • • • • • Energy density from < 20 (Pb) , 35 (NiCd), 75 (NiMeH) to 150 Wh/kg (Li-ion) Cycling life 220-700 (Pb) 500 – 2000 (Ni-Cd) Voltage 2 V (Pb) 1.2 V (Ni-Cd) Flat discharge profiles Poor charge retention (shelf life of Ni-Cd – fully discharged, Pb must be kept charged because of sulfation of plates) Vented constructions – evolution of H2 / O2 Tight closure of cells – oxygen recombination ( at end of charge oxygen developing in anodic process diffuses to cathode and oxidates surplus of cathode material – no overpressure : Valve-Regulated-Lead-Acid sealed Ni-Cd WUT - MESC - Galvanic Cells II 35 Lead-acid accumulator WUT - MESC - Galvanic Cells II 36 cycle „negative mass” „positive mass” Pb → PbSO4 (oxidation) PbO2 → PbSO4 (reduction) Concentration of H2SO4 ↓ Concentration of H2SO4 ↓ PbSO4 → Pb PbSO4 → PbO2 (oxidation) discharge (reduction) charge Concentration of H2SO4 ↑ Concentration of H2SO4 ↑ WUT - MESC - Galvanic Cells II 37 Phenomena in discharge cycle • CH2SO4 • PbSO4 – insulator ( ca. 1010 Ώcm) • Vmol PbSO4 > Vmol Pb, PbO2 worse porosity diffusion of the electrolyte into the structure impaired R int What happens with: current density at U = const ? Voltage at I = const. ? WUT - MESC - Galvanic Cells II 38 WUT - MESC - Galvanic Cells II 39 WUT - MESC - Galvanic Cells II 40 Alkaline accumulators • Ni –Cd , Ni – Fe, Ni – MeH ( 1.2V) Ag – Zn ( 1.5V) Ni – Zn (1.6V) • Cathode Ni NiIII OOH + H20 + eNi(OH)2 + OH- • Anode Cd Cd + 2(OH-) • Ag-Zn : Ag2O + H2O + 2e Zn + 2(OH-) Cd(OH)2 + 2e2Ag + 2 OHZn(OH)2 + 2e WUT - MESC - Galvanic Cells II 41 Ni-Cd accumulator cycle „masa ujemna” „masa dodatnia” NiOOH → Ni(OH)2 (reduction) discharge Cd → Cd(OH)2 (oxidation) Cd(OH)2 → Ni II(OH)2 → Ni IIIOOH (oxidation) (reduction) charge WUT - MESC - Galvanic Cells II 42 (further electrolysis after charging effects in evolution of O2) ((further electrolysis after charging effects in evolution of H2) WUT - MESC - Galvanic Cells II 43 Oxygen and hydrogen formation in cells • Reactions possible in water solution • Equilibrium potentials : E (H+/H2) = 0V , E (OH-/O2) = 0.4 V • BUT – overpotentials due to phenomena at gas-solid electrode phase boundary make true potentials higher • For different metals the hydrogen evolution potential grows from: Pt - Ni - Ag - Zn - Cd - Pb (and compounds) • Still, at the end of charge/discharge cycle co-evolution of gases in cells occurs • In effect: overpressure inside the cell, - H2 i O2 • „oxygen recombination” – electrodes not equivalent in charge, ex. QCd > QNi WUT - MESC - Galvanic Cells II 44 Basic secondary cells Ni-Cd •Pocket electrode construction of electrodes •Sintered plates Pb acid •Pasted plates •Tubular positive plates •Plante’ design WUT - MESC - Galvanic Cells II 45 Technology of electrode masses in Ni-Cd • Electrodes prepared in discharged state : Ni(OH)2 and Cd(OH)2 as Compresed powder NiSO4→Ni(OH)2 CdSO4 →Cd(OH)2 Encapsulated in steel/Ni pocket • • • • • Sintered plate Porous Ni plate Impregnated with Ni , Cd salts Transformed to hydroxides „in situ” Additives: graphite ,”-” mass – Fe+ Ni (→ Cd crystallization) Formation of plates : several charge-discharge cycles Assembly and hermetic closure Separators – ionic conductivity and oxygen diffusion (thickness ca0.2 mm) For O2 recombination higher capacity of „-” mass (Cd) – fully charged Ni mass – O2evolution – diffusion – Cd oxidised to CdO, no possiblity of H2 formation WUT - MESC - Galvanic Cells II 46 Nickel/Metal Hydride • • • • Anode : 2 NiO(OH) + 2 H2O + 2e → Ni(OH)2 + 2 OHCathode : H2 + 2 (OH-) → 2 H2O + 2e Hydrogen stored as hydride in metallic phase, Capacity of metal hydride electrode c. 0.4 Ah/g -- comparable with Cd and Ni sintered plates 0.3-0.5 Ah/g WUT - MESC - Galvanic Cells II 47 Scheme for reaction mechanism at Me electrode charge H2O Hads overcharge discharge OH- OH- H2 Hads H2O H2O O2 Hads Me-H Reversibility of electrode reaction, catalytic for H adsorption and H-O2 recombination WUT - MESC - Galvanic Cells II 48 Hydrogen absorbing alloys • • A – metal forming stable hydrides B – weak hydrides, catalyst, resistance to corrosion, control Hads pressure Class (basis) Components Storage Ah/kg Remarks AB5 (LaNi5) A: Mischmetall, La, Ce, Ti B: Ni, Co, Mn, Al ≈ 300 Mostly used AB2 (TiNi2) A: Zr, Ti B: Ni, Fe, Cr, V ≈ 400 „Ovonic” alloys • Nickel - catalyst for H2 dissociation,, regulator for Zr, Ti, V hydride formation, WUT - MESC - Galvanic Cells II 49 Some details on production of alloys • Ni mass – traditional, new technologies for MeH electrode powder • Ovonic alloy – example : main components : Zr-Ti-V-Ni + Cr, Mn, Co, Fe... • Preparative technics: electric arc or inductive oven, Ar atmosphere • Production of powder : hydrogenation of cast alloy (volume expansion = crushing of a piece), followed by mechanical pulverisation • Sintered plates : MeH powder + Ni, Ni(CO)5 + resin → pressing and sintering under vacuum WUT - MESC - Galvanic Cells II 50 Lithium cells Atomic mass LITHIUM ZINC -3.05 -0.76 Melting point (oC) 181 419 Density (kg/m3) 534 7100 Elchem. equivalent (Ah/g) 3.86 0.82 Standard potential (V) Anodic reaction : Li = Li+ + 1e •Reactivity of metallic lithium: reduces most substances (even Teflon®) •Stable passivation – key to electrode stability •What shall we do with excess lithium? •Transport and consume in cathode reaction •Why not leave lithium cations in the electrolyte? WUT - MESC - Galvanic Cells II 51 Anode Metallic Li (foil) Intercalation : Li – Li+ in matrix Stable passivation layer on discharge Carbon materials : coke, graphite etc. 6 – 12 C atoms take 1 lithium atom into the structure Charge : mossy, dendritic deposit – corrosion of fresh Li internal shortcutting Main application – primary cells Rechargeable – attempts with polymer electrolytes First cycle – formation of SEI (Solis Electrolyte Interface) portion of Li used for reaction with electrolyte Some transition metal compounds Capacity: 3.86Ah/g, in accu < 1 Ah/g WUT - MESC - Galvanic Cells II Capacity: 0.372 Ah/g 52 Irreversible loss of capacity on first cycle, electrode : artificial graphite WUT - MESC - Galvanic Cells II 53 WUT - MESC - Galvanic Cells II 54 Cathodes • Redox potentials in 0 – 1 V range - OCV of Li cells from 3 to 4 V Solid: MexOy Reduction of Me ion to lower oxidation state, like MnIVO2 – MnIIIO2 Topotactic reaction Insertion of Li+ into host structure Soluble SO2 + 2e → S2O42( in solution, + Lisalt ex. LiAlCl4) Thionyl chloride: SOCl2 + 4e → S + SO2 Sulfuryl chloride: SO2Cl2 + 2e → SO2 (solvents for Li salt) Some other: V2O5, (CF)n, TiS2 Capacities: 0.31(MnO2), 0.86(CF) Ah/g Capacities : ≈ 0.4 Ah/g WUT - MESC - Galvanic Cells II 55 WUT - MESC - Galvanic Cells II 56 Carbon layers in regular graphite Layered structure of LiCoO2 WUT - MESC - Galvanic Cells II 57 Electrolytes Conductivity, Li+ transference number Electrochemical and thermal stability Liquid organic •Aprotic •Protective passivation layer on Li •Li salts solute and dissociate •Appropiate physical features: stable non-toxic, nonflammable •Conductivities ≈ 1e-3 S/cm Polymer Li conduction via coordination sites on polymer chains (ex. Poly(ethylenoxide) Solid foils, processable More stable against Li Conductivities : 1e-7 –1e-4 S/cm Gel 2 in 1 : polymer matrix immobilizing liquid electrolyte WUT - MESC - Galvanic Cells II 58 Solution Ionic conductivity (20oC) S/cm 1M H2SO4 10-1 Nafion® foil (H+) 10-2 1M LiBF4 in acetonitrile 10-3 PEO-LiClO4 complex 10-6 WUT - MESC - Galvanic Cells II 59 WUT - MESC - Galvanic Cells II 60 WUT - MESC - Galvanic Cells II 61 WUT - MESC - Galvanic Cells II 62 Step-wise intercalation of Li into graphite, observed as voltage plateaux WUT - MESC - Galvanic Cells II 63 Parameters and definitions • • • • • • EMF or OCV nominal voltage (accepted as typical for a certain battery) End (cut-off) voltage Theoretical capacity : comes from amount of active materials Rated capacity Energy density (Watthour/l) and specyfic energy (Watthour/kg) : theoretical E = Q × EMF, practical E = Q×ΔU • Power density • Shelf life WUT - MESC - Galvanic Cells II 64 General discharge profile - elements • Discharge of a galvanic cell WUT - MESC - Galvanic Cells II 65 C - rate • Charge / discharge current of a battery, given as I (amper) = Cn (amperhours) . M (multiply or fraction of C) !!! Traditional convention, but units are uncorrect!!! However, most producers and studies use this measure !!! • Ex. For a 250 mAh rated battery (declaration of producer) : 1C – rate = 250 mA 0.1C –rate = 25 mA and so on • We can compare batteries at equal C-rates or study discharge for a given battery at different C-rates WUT - MESC - Galvanic Cells II 66 Discharge profiles 1. Flat – minimal change in reactants and products 2. Step-wise – change in reaction mechanism and potential 3. Sloping - composition, internal R ... Change continouosly WUT - MESC - Galvanic Cells II 67 WUT - MESC - Galvanic Cells II 68 Continuous and intermittent discharge Possibilty for partial recovery of voltage during pause WUT - MESC - Galvanic Cells II 69 Discharge • Discharge mode – constant current / resistance / power (time to reach cut-off U may differ) • Electrode design = f (type of service) • Max. quantity of active material = max. energy supply • Max. electrode surface = high discharge rate (current, power) • Possibility of partial restoration of voltage – stand-by intervals WUT - MESC - Galvanic Cells II 70 WUT - MESC - Galvanic Cells II 71