Effect of impregnation solvent and manganese content

advertisement

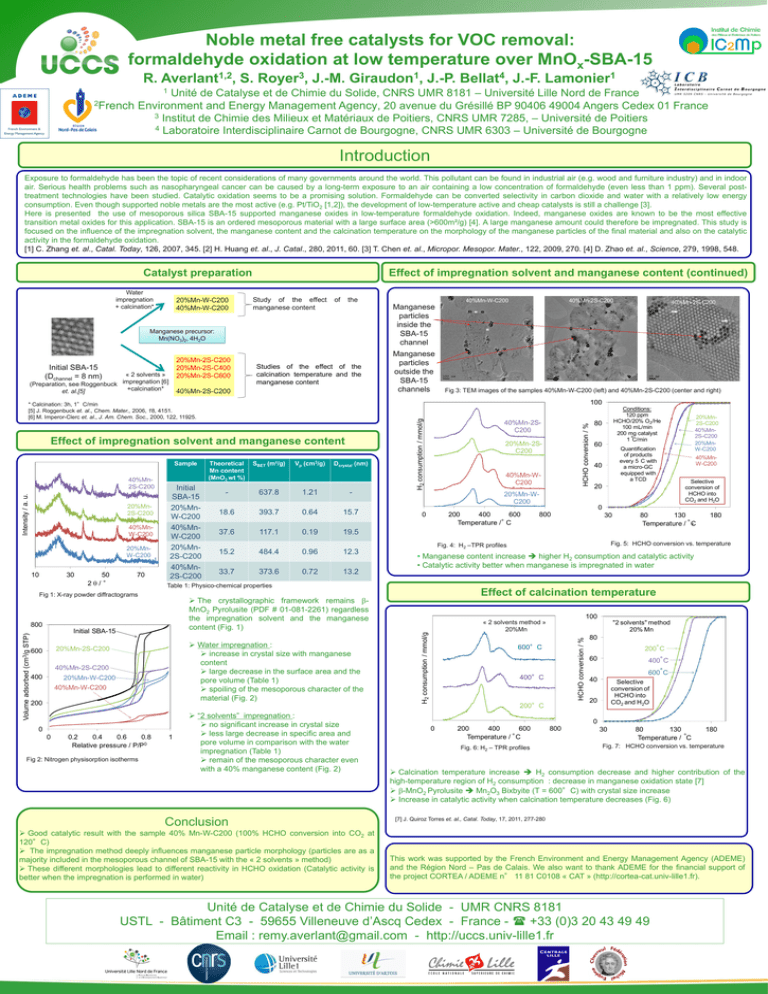

Noble metal free catalysts for VOC removal: formaldehyde oxidation at low temperature over MnOx-SBA-15 R. Averlant1,2, S. Royer3, J.-M. Giraudon1, J.-P. Bellat4, J.-F. Lamonier1 Unité de Catalyse et de Chimie du Solide, CNRS UMR 8181 – Université Lille Nord de France 2French Environment and Energy Management Agency, 20 avenue du Grésillé BP 90406 49004 Angers Cedex 01 France 3 Institut de Chimie des Milieux et Matériaux de Poitiers, CNRS UMR 7285, – Université de Poitiers 4 Laboratoire Interdisciplinaire Carnot de Bourgogne, CNRS UMR 6303 – Université de Bourgogne 1 Introduction Exposure to formaldehyde has been the topic of recent considerations of many governments around the world. This pollutant can be found in industrial air (e.g. wood and furniture industry) and in indoor air. Serious health problems such as nasopharyngeal cancer can be caused by a long-term exposure to an air containing a low concentration of formaldehyde (even less than 1 ppm). Several posttreatment technologies have been studied. Catalytic oxidation seems to be a promising solution. Formaldehyde can be converted selectivity in carbon dioxide and water with a relatively low energy consumption. Even though supported noble metals are the most active (e.g. Pt/TiO2 [1,2]), the development of low-temperature active and cheap catalysts is still a challenge [3]. Here is presented the use of mesoporous silica SBA-15 supported manganese oxides in low-temperature formaldehyde oxidation. Indeed, manganese oxides are known to be the most effective transition metal oxides for this application. SBA-15 is an ordered mesoporous material with a large surface area (>600m²/g) [4]. A large manganese amount could therefore be impregnated. This study is focused on the influence of the impregnation solvent, the manganese content and the calcination temperature on the morphology of the manganese particles of the final material and also on the catalytic activity in the formaldehyde oxidation. [1] C. Zhang et. al., Catal. Today, 126, 2007, 345. [2] H. Huang et. al., J. Catal., 280, 2011, 60. [3] T. Chen et. al., Micropor. Mesopor. Mater., 122, 2009, 270. [4] D. Zhao et. al., Science, 279, 1998, 548. Catalyst preparation 20%Mn-W-C200 40%Mn-W-C200 Study of the effect manganese content of the 40%Mn-2S-C200 100 * Calcination: 3h, 1°C/min [5] J. Roggenbuck et. al., Chem. Mater., 2006, 18, 4151. [6] M. Imperor-Clerc et. al., J. Am. Chem. Soc., 2000, 122, 11925. Effect of impregnation solvent and manganese content Sample 20%Mn2S-C200 40%MnW-C200 20%MnW-C200 10 30 50 2/° 70 Initial SBA-15 20%MnW-C200 40%MnW-C200 20%Mn2S-C200 40%Mn2S-C200 Volume adsorbed (cm3/g STP) Initial SBA-15 1.21 Dcrystal (nm) - 18.6 393.7 0.64 15.7 37.6 117.1 0.19 19.5 15.2 484.4 0.96 12.3 33.7 373.6 0.72 13.2 Water impregnation : increase in crystal size with manganese content large decrease in the surface area and the pore volume (Table 1) spoiling of the mesoporous character of the material (Fig. 2) 20%Mn-2S-C200 40%Mn-2S-C200 20%Mn-W-C200 40%Mn-W-C200 200 0 0 637.8 Vp 40%Mn-WC200 0 200 400 600 Temperature /°C 0.2 0.4 0.6 0.8 Relative pressure / P/P0 Fig 2: Nitrogen physisorption isotherms 1 “2 solvents” impregnation : no significant increase in crystal size less large decrease in specific area and pore volume in comparison with the water impregnation (Table 1) remain of the mesoporous character even with a 40% manganese content (Fig. 2) Conclusion Good catalytic result with the sample 40% Mn-W-C200 (100% HCHO conversion into CO2 at 120°C) The impregnation method deeply influences manganese particle morphology (particles are as a majority included in the mesoporous channel of SBA-15 with the « 2 solvents » method) These different morphologies lead to different reactivity in HCHO oxidation (Catalytic activity is better when the impregnation is performed in water) Conditions: 120 ppm HCHO/20% O2/He 100 mL/min 200 mg catalyst 1° C/min 80 60 Quantification of products every 5 C with a micro-GC equipped with a TCD 40 20 20%Mn-WC200 20%Mn2S-C200 40%Mn2S-C200 20%MnW-C200 40%MnW-C200 Selective conversion of HCHO into CO2 and H2O 0 800 30 80 130 Temperature / ° C ° 180 Fig. 5: HCHO conversion vs. temperature Fig. 4: H2 –TPR profiles • Manganese content increase higher H2 consumption and catalytic activity • Catalytic activity better when manganese is impregnated in water Effect of calcination temperature The crystallographic framework remains MnO2 Pyrolusite (PDF # 01-081-2261) regardless the impregnation solvent and the manganese content (Fig. 1) 800 400 - SBET (m²/g) 20%Mn-2SC200 Table 1: Physico-chemical properties Fig 1: X-ray powder diffractograms 600 Theoretical Mn content (MnO2 wt %) (cm3/g) 40%Mn-2SC200 100 « 2 solvents method » 20%Mn H2 consumption / mmol/g Intensity / a. u. 40%Mn2S-C200 40%Mn-2S-C200 Fig 3: TEM images of the samples 40%Mn-W-C200 (left) and 40%Mn-2S-C200 (center and right) HCHO conversion / % « 2 solvents » (Preparation, see Roggenbuck impregnation [6] +calcination* et. al.[5] Studies of the effect of the calcination temperature and the manganese content Manganese particles outside the SBA-15 channels "2 solvents" method 20% Mn HCHO conversion / % Initial SBA-15 (Dchannel = 8 nm) 40%Mn-2S-C200 Manganese particles inside the SBA-15 channel Manganese precursor: Mn(NO3)2, 4H2O 20%Mn-2S-C200 20%Mn-2S-C400 20%Mn-2S-C600 40%Mn-W-C200 H2 consumption / mmol/g Water impregnation + calcination* Effect of impregnation solvent and manganese content (continued) 600°C 400°C 200°C 80 200° C 60 400° C 600° C 40 Selective conversion of HCHO into CO2 and H2O 20 0 0 200 400 600 Temperature / ° C Fig. 6: H2 – TPR profiles 800 30 80 130 Temperature / ° C 180 Fig. 7: HCHO conversion vs. temperature Calcination temperature increase H2 consumption decrease and higher contribution of the high-temperature region of H2 consumption : decrease in manganese oxidation state [7] -MnO2 Pyrolusite Mn2O3 Bixbyite (T = 600°C) with crystal size increase Increase in catalytic activity when calcination temperature decreases (Fig. 6) [7] J. Quiroz Torres et. al., Catal. Today, 17, 2011, 277-280 This work was supported by the French Environment and Energy Management Agency (ADEME) and the Région Nord – Pas de Calais. We also want to thank ADEME for the financial support of the project CORTEA / ADEME n° 11 81 C0108 « CAT » (http://cortea-cat.univ-lille1.fr). Unité de Catalyse et de Chimie du Solide - UMR CNRS 8181 USTL - Bâtiment C3 - 59655 Villeneuve d’Ascq Cedex - France - +33 (0)3 20 43 49 49 Email : remy.averlant@gmail.com - http://uccs.univ-lille1.fr