Hydrogen Fuel Cell Update

advertisement

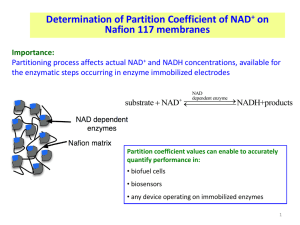

The PEM Fuel Cells Nafion Thermal Behavior Nafion 115 80oC o 130 C Cell Potential / V 1.0 Silicon Oxide/Aciplex 1004 130 oC 0.8 0.6 0.4 0.2 0.0 0 200 400 600 800 1000 1200 1400 1600 1800 Current Density / mA cm2 Frick Laboratory, Princeton University Is the Metal Oxide Phase Water Retentive? §The composite typically contains 3-6 wt% metal oxide. §TGA indicates the same water content and dehydration temperature for pure Nafion and the composite. §The conductivity of the composite measured in a mechanically unconstrained environment is the same or slightly worse than the conductivity of pure Nafion. The metal oxide is not simply providing a water retentive or hydrated interface. Frick Laboratory, Princeton University If it’s not a question of direct dehydration, then what is occurring? • First, we will seek a molecular picture. • Then, we will attempt to make connections between our understanding of the molecular structure and bulk materials properties. Frick Laboratory, Princeton University Effect of Metal Oxide Identity on Membrane Performance 1.0 Cell Potential / V 130o C (Degussa-Huls) TiO2; 21nm; 50 2 m /g (R - 0.18) 0.8 2 SiO2; 20nm; 90 m/g (R - 0.21) 2 Al2O3; 13 nm; 100 m /g (R - 0.76) Recast Nafion Control (R - 0.5) 0.6 0.4 0.2 0 500 1000 1500 -2 Current Density / mA cm Frick Laboratory, Princeton University Interfacial Chemistry is Critical 1.0 TiO2 (AA)/Recast Nafion; 130˚C Cell Potential / V unmodified (R - 0.50) silylated (R - 0.29) H2SO4, HNO , "degreased" (R - 0.25) 3 0.8 0.6 0.4 0.2 0 200 400 600 800 1000 1200 1400 1600 Current Density / mA-2cm Frick Laboratory, Princeton University The Effect of Relative Humidity on Recast Nafion C ontrol m em brane(H 2 -O 2 ) 0 1.0 130 C 30 psig 100% R H 88% R H 75% R H 0.9 cell potential(V ) 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 200 400 600 800 1000 1200 1400 1600 2 current density (m A /cm ) Frick Laboratory, Princeton University 75% Relative Humidity 0 130 C 75% R H C ontrol R ecast D egussa H uls SiO 2 Alfa Aesar SiO 2 D egussa H uls TiO 2 Alfa Aesar TiO 2 1.0 0.9 cell potential(V) 0.8 0.7 0.6 125µ Film 0.5 3 atm pressure 0.4 0.3 40 ml/min 0.2 0.1 0 200 400 600 800 1000 1200 1400 2 current density (m A/cm ) Frick Laboratory, Princeton University Potential Chemical Interactions ----CF2-CF2--OH OH Metal Oxide -----CF----SO3- HO Metal Oxide -----CF----O=S=O O OH Ti Metal Oxide Frick Laboratory, Princeton University Temperature Programmed Decomposition (TGMS) of Nafion 117 m/z 18 H2O MS abundance / a.u. Thermal decomposition of Nafion m/z 131 C3F5 2nd step C3F5+ m/z 64 SO2 m/z 47 COF CFO + 0 - Weight loss/ % -10 -20 H2O -30 H2O -40 SO2 SO2 C3F5+ CFO+ -50 1st step H2O -60 -70 0 100 200 300 400 500 Temperature / C Frick Laboratory, Princeton University TG-MS Profile of Nafion/TiO2 Composite Membranes m/z 18 H2O MS abundance / a.u. Thermal decomposition of Nafion 3rd step m/z 131 C3F5 C3F5+ m/z 64 SO2 2nd step CFO + m/z 47 COF 0 Weight loss/ % -10 - -20 HO -30 H2O -40 SO2 -50 C3F5+ CFO+ TiO2 1st step SO2 H2O -60 -70 0 100 200 300 400 500 Temperature / C Frick Laboratory, Princeton University TPD-MS profiles of Nafion/Inorganic composite membranes SO2 (m/z 64) CFO (m/z 47) Nafion + 3% SiO2 Nafion117 Nafion + 3% TiO2 Nafion + 3% Al2O3 Nafion + 3% SiO2 Intensity / a.u. Intensity / a.u. Nafion117 Nafion + 3% TiO2 Nafion + 3% ZrO2 200 250 300 350 400 Nafion + 3% Al2O3 Nafion + 3% ZrO2 200 250 Temperature / C Nafion117 Nafion + 3% TiO2 Nafion + 3% Al2O3 Nafion + 3% SiO2 Temperature / C 350 400 Intensity / a.u. Intensity / a.u. Nafion + 3% SiO2 Nafion + 3% ZrO2 300 400 C3F5 (m/z 131) Nafion117 Nafion + 3% TiO2 250 350 Temperature / C H2O (m/z 18) 200 300 - Nafion + 3% Al2O3 Nafion + 3% ZrO2 200 250 300 350 400 Frick Laboratory, Princeton University Temperature / C Molecular Model MOx •Crosslinking controls the mechanical properties of the polymer •Glass transition temperature •Bulk rigidity – better water retention under stress load Frick Laboratory, Princeton University Dependence of Nafion Glass Transition on Metal Oxide Frick Laboratory, Princeton University SAXS Studies Frick Laboratory, Princeton University Order-Disorder Transition Crystalline Heat Self Assembled Disordered Frick Laboratory, Princeton University Membrane Mechanical Properties Affect Cell Response Ionic inclusions swell with water uptake, requiring the membrane to push the electrodes apart. Frick Laboratory, Princeton University Stress-Strain Response 5.5x106 Stress (N/m 2) 5.0x106 4.5x106 4.0x106 Metal Oxide Composite 6 3.5x10 Nafion 112 3.0x106 2.5x106 2.0x106 1.5x106 1.0x106 5.0x105 0.0 0 20 40 60 80 100 120 140 160 180 200 Strain(%) Frick Laboratory, Princeton University Too Much of a Good Thing is Bad Applied Pressure by Current Collector Plates 8 7 Swelling Pressure of Polymer Membrane 5 4 3 2 60 35 34.5 current oscillations observed 1 34 0 0 0.5 1 1.5 2 2.5 33 55 32.5 32 31.5 Turns past finger tight 31 30.5 50 20000 22000 24000 26000 28000 30 30000 Time (s) Frick Laboratory, Princeton University Power (mW) 33.5 Current (mA) MEA Resistance (ohm) 6 Carbon support membrane Membrane Swelling (a)The membrane is in contact with the catalyst support particles. (b)Applied pressure enhances the membrane/catalyst contact. (c)Additional pressure further increases the membrane/catalyst contact. However, the larger pressure forces water out of the membrane. Frick Laboratory, Princeton University Hydrogen Crossover Crossover Current (mA/cm 2) 950 3.0 900 2.0 850 1.0 800 0.0 125µm 40µm 40µm Composite Open Circuit Voltage (mV) 1000 4.0 Membrane Frick Laboratory, Princeton University What Role Does the Metal Oxide Play? •Increased Tg allows maintenance of hydrated proton conduction paths at elevated temperatures. •Improved mechanical rigidity allows for dimensional stability under conditions where water content of the membrane may be changing. •Maintains good catalyst contact on deswelling •Eliminates water loss on swelling. Frick Laboratory, Princeton University Carbon Monoxide Tolerance o Nafion 115 - 80 C Pt Anode w/o CO w/100 ppm CO 1.0 Cell Potential / V 0.9 o TiO - 130 C Pt/Ru Anode 2 w/100 ppm CO w/500 ppm CO 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0 200 400 600 800 1000 1200 1400 -2 1600 Current Density / mA cm Frick Laboratory, Princeton University Summary High Temperature Nafion Based PEM Fuel Cells overcome several limitations associated with current cell design Addition of a metal oxide phase affects the mechanical properties of the membrane: Increased Tg Improved gas barrier Mitigation of swelling/deswelling effects Frick Laboratory, Princeton University Bonus Material (It’s not electrochemistry, but it is interesting) So, How Does One Store Hydrogen on the Run? Storage Issues Safety For mobile applications range & power should be maintained. 5-10Kg of H2 needed for a 65-75kW engine. H2 feed rate is ~1000 liters/minute Weight Effective Density of Hydrogen Volume Requirements Refill Size Geometry Availability Recharge rate. Cost Frick Laboratory, Princeton University Hydrogen Storage Phases Limiting Densities of Molecular Hydrogen Solid Hydrogen (4.2K) Moles Hydrogen Atom/cm3 0.088 Liquid Hydrogen (20K) 0.070 100% Hydrogen Gas 200bar (300K) 0.016 ~1% Hydrogen Phase W eight Pe rcent 100% Frick Laboratory, Princeton University Storage Options Standard steel tanks (2000-5000psi) Known technology. Good Safety Record Tanks are challenging to fill because hydrogen heats upon expansion Heavy Subject to hydrogen imbrittlement Forms projectiles if structure is breached Storage capacity is only 0.5-1% by weight Poor volumetric storage due to non-ideality of hydrogen: n 2 a P 2 V nb nRT V a 0.2444 b 0.02661 ~ 20% volumet ric expansion at 5000psi Frick Laboratory, Princeton University Storage Options Composite Tanks (~10,000psi) High storage capacity: Light weight Can store 7% H2 by weight! Does not fragment upon failure Cost Frick Laboratory, Princeton University Storage Options Generation on the fly: in-situ or ex-situ reforming of hydrocarbon fuels using an on-site reformer. Energy density of gasoline Easy access to fuel (gasoline stations) Systems integration is poor No carbon mitigation. Solid-state storage by intercalation (metal hydrides, carbons) Safe Heavy Expensive Chemical thermodynamics and kinetics are difficult Significant heating is required to release the hydrogen ∆H losses up to 30% are typical with operating temperatures of 200-300C. Tank filling is very exothermic Chemical kinetics are a difficult to handle Frick Laboratory, Princeton University Hydride Storage Capacity Metal Hydride Storage Systems Hydrogen Phase LaNi5H6 Moles Hydrogen Atom/cm3 0.091 W eigh t Pe rcen t 1.37% TiFeH2 0.10 1.89% Mg2NiH4 0.098 3.6% MgH2 0.11 7.6% Frick Laboratory, Princeton University Storage Options Chemical Hydrides “Hydrogen on Demand” (Sodium Borohydride) Not flammable High Effective hydrogen pressure (~7000psi) Low Volume Simple system Chemical Safety Recyclable Cost?? lyst NaBH4 Aqueous Base Cata H2 NaBO2 2H2O Frick Laboratory, Princeton University