A/F Sensor PowerPoint

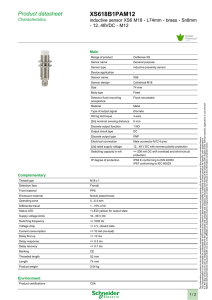

advertisement

OVERVIEW OF A BASIC AIR/FUEL SENSOR PRODUCED BY THE BUREAU OF AUTOMOTIVE REPAIR Written by Wayne Brumett A/F SENSOR OPERATION The following is a simplistic explanation of how a wideband (broad planar) Air/Fuel (A/F) Sensor operates. This is a complicated subject area, and not easily understood by many. In an attempt to reduce the level of confusion, and enhance understanding, this presentation covers just the very basic areas of this subject. To this endeavor, some of the more technical material was intentionally left out of the program. A/F SENSOR OPERATION A simple O2 sensor is constructed with: •Platinum Electrodes (2); and •Zirconium Dioxide element (between the electrodes) A/F SENSOR OPERATION As exhaust displaces the oxygen in the exhaust pipe: •The platinum electrodes react (catalytic reaction) to the potential difference in oxygen content between the outside air and the inside of the exhaust pipe. • This potential difference creates an electrical current (voltage). Low O2 Fresh Air A/F SENSOR OPERATION The current is developed, because the platinum plate in the exhaust stream will draw oxygen (O2) ions from the fresh air side to the exhaust, as part of the catalytic reaction. It is the transfer of the O2 ions through the platinum plates that creates the current flow. The less O2 in the exhaust, the higher the current flow (voltage) due to the larger potential difference in ion concentration from the outside air to the inside of the exhaust. + - PCM O2 ION Fresh Air A/F SENSOR OPERATION The Zirconium oxygen sensor just described worked well for its time, but unfortunately, this type of sensor was prone to producing wide voltage fluctuations (above and below 450 mV), and was limited in its range. The PCM was forced to make fuel/timing adjustment decisions, based on an average of these fluctuating signals. With the government requirement for low and ultra low vehicle emissions, a more accurate method of determining the exhaust O2 content and a wider range of Air/Fuel ratio (upwards of 23/1) was needed to achieve these new low emission levels. A/F SENSOR OPERATION A new sensor was developed, called the wideband (broad planar) Air/Fuel sensor. This sensor is based on the operation of the old O2 sensor just discussed. This sensor is actually two O2 sensors housed in one area, with a common chamber between them. A/F SENSOR OPERATION The wideband (broad planar) Air/Fuel sensor adds two chambers to the original Zirconium sensor: • A Diffusion Chamber. •An Air Reference Chamber. AIR REFERENCE CHAMBER DIFFUSION CHAMBER A/F SENSOR OPERATION Between the Diffusion Chamber and the Air Reference Chamber is the second O2 sensor: • Platinum Electrodes (2) • Zirconium Dioxide Element (between the electrodes) • These plates are wired in a parallel circuit with the plates to the left (exhaust stream) Diffusion Chamber AIR REFERENCE CHAMBER A/F SENSOR OPERATION In this circuit, the two sensors share a common (floating) ground. The sensor that is in contact with the exhaust stream is commonly referred to as the “sense” (signal) cell, which we will call Sensor #1. The sensor in contact with the Diffusion Chamber and the Air Reference Chamber is commonly referred to as the (Ion) “Pump” cell, which we will call Sensor #2. Sensor #1 Ground (floating) Sensor #2 AIR REFERENCE CHAMBER Diffusion Chamber A/F SENSOR OPERATION System Operation: Sensor #1 operates as a traditional O2 sensor, sending a high voltage signal (above 450mV) to the PCM when the A/F ratio is rich (low O2) , and low voltage signal (below 450 mV) when the A/F ratio is lean (high O2). The purpose of the Diffusion Chamber and Sensor # 2, is to counteract the change in voltage of Sensor #1, and keep it at 450 mV (stoichiometric). Sensor #1 Ground (floating) Sensor #2 AIR REFERENCE CHAMBER A/F SENSOR OPERATION To keep Sensor # 1 at 450 mV, requires that Sensor # 2 provide a current flow (positive or negative) that will move the O2 ions in the opposite direction that Sensor # 1 has them moving (relative to exhaust O2 content). Example: If a rich mixture enters the exhaust stream (low O2), many O2 ions will flow from the Diffusion Chamber, through Sensor # 1, towards the exhaust stream. The voltage on Sensor # 1 will rise. Rich Mixture (Low O2) Sensor #1 Ground (floating) Sensor #2 O Diffusion 2 Io Chamber n AIR REFERENCE CHAMBER A/F SENSOR OPERATION When Sensor # 1 voltage rises above 450 mV (rich mixture), the PCM reacts by providing a negative (-) current flow on Sensor # 2 to move (pump) the O2 ions in the opposite direction, back towards the Diffusion Chamber, thus limiting the O2 ion flow through Sensor #1. Rich Mixture (Low O2) Sensor #1 Ground (floating) Sensor #2 O 2 Io n O Diffusion 2 Io Chamber n AIR REFERENCE CHAMBER This action brings Sensor #1 voltage down to 450 mV. PCM Sends (-) amp signal to Sensor #2 A/F SENSOR OPERATION When the O2 content in the exhaust is high (lean mixture – low O2 ion transfer), the system reacts in the opposite manner. Lean Mixture (High O2) Sensor #1 Sensor #1 sends a low voltage signal (under 450 mV) to the PCM. The PCM sends a positive (+) amperage signal to Sensor # 2, to pump more O2 ions from the Air Reference Chamber through the Diffusion Chamber, to the exhaust stream (through Sensor #1’s platinum plates). This action causes more ions to flow through Sensor #1 and brings the voltage up to 450 mV. Ground (floating) Sensor #2 O 2 Io O n Diffusion 2 Io Chamber n AIR REFERENCE CHAMBER PCM Sends (+) amp signal to Sensor #2 A/F SENSOR OPERATION As you can see, Sensor # 2 controls Sensor # 1’s voltage, by applying a positive or negative current flow. The PCM monitors the current flow change on Sensor # 2, and makes fuel and timing corrections based on the size of these changes. If there is zero current flow on Sensor # 2, the air/fuel ratio is at equilibrium (stoichiometric) 14.7 to 1 A/F Ratio Sensor #1 Ground (floating) Sensor #2 AIR REFERENCE CHAMBER A/F SENSOR OPERATION THE END