File - Garbally Chemistry

advertisement

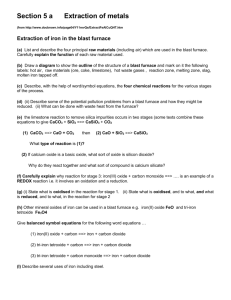

Options(electrochemistry) Options History • Galvani noted the muscular reaction in dissected frog’s legs when they were in contact with two different metals. Allesandro Volta • Volta produced cells and batteries by separating copper and zinc plates with salt solution. Humphry Davy • Humphry Davy passed electric current into molten salts and electrolysed them. Discovered Na, K, Ca, Mg, Ba and Sr. Michael Faraday • Michael Faraday worked with Davy. He discovered the electric motor. • Furthered the study of electrolysis (Faraday’s laws). Electrochemistry • A simple cell consists of two different metals immersed in a solution of ions. The voltage of the cell depends on the difference in activity between the two metals. • The standard electrode potential is measured against the hydrogen electrode. A TYPICAL COMBINATION OF HALF CELLS 1.10V ZINC COPPER ZINC SULPHATE (1M) COPPER SULPHATE (1M) E° = - 0.76V E° = + 0.34V zinc is more reactive - it dissolves to give ions Zn(s) ——> Zn2+(aq) + 2e¯ the electrons produced go round the external circuit to the copper electrode electrons are picked up by copper ions As a result, copper is deposited overall reaction Cu2+(aq) + 2e¯ ——> Cu(s) Zn(s) + Cu2+(aq) ——> Zn2+(aq) + Cu(s) Corrosion Corrosion is any undesired process whereby a metal is converted to one of its compounds. It can be prevented by: – – – – Painting and greasing. Galvanising-coating with zinc Coating the surface with another metal-tin can Using sacrificial anodes. Iron placed in contact with a metal that is more easily oxidised – Alloying with another element- stainless steel is a mixture of Iron, chromium and carbon. Rusting of Iron Electrolysis of Molten Salts. Electrolysis of molten Lead Bromide(PbBr2). • Cathode reaction Pb2+ + 2e– Pb • Anode reaction 2Br– Br2 + 2e– Electrolysis of Sodium from molten Sodium Chloride(Downs cell) The Downs cell consists of a graphite anode(doesn’t react with chlorine) surmounted by a hood to remove chlorine gas, and a circular steel cathode. Added to the Sodium Chloride is Calcium Chloride which helps to reduce the melting point. Cathode reaction: Na+ + e- Na Anode Reaction: Cl- -e- ½ Cl2 Downes cell 3. Extraction of Aluminium from Bauxite 2 stages Aluminium oxide extracted from Bauxite. 1. Bauxite is crushed and mixed with hot Sodium Hydroxide. 2. Digestion- The mixture is heated and the hydrated Aluminium oxide reacts with the Sodium Hydroxide to form Sodium Aluminate. AL2O3.3H2O +2NaOH 2NaAlO2 + 4H2O 3. Removal of impurities by filtration.(Red Mud) 4. Precipitation of Aluminium Oxide(Seeding) 4NaAlO2 + 4H2O Al2O3.3H2O + 2NaOH 5.Removal of water of Crystallisation Production of Aluminium from Alumina. • In the smelter the alumina is heated with cryolite which lowers the mp. • Anode and Cathode are made of Graphite Production of Aluminium from Alumina • During the electrolysis, the following reactions occur: • Cathode: 2Al3+(l) + 6e- → 2Al(l) • Anode: 3O2-(l) - 6e- → 11/2O2(g) • The molten aluminium formed settles at the bottom of the tank, and is siphoned from there. • The electrolysis is carried out at a high temperature, at which the large carbon anodes are steadily burnt away by the oxygen liberated there, and have to be replaced at regular intervals. • The electrolysis of alumina consumes enormous amounts of electricity, and is therefore normally carried out where electricity is relatively cheap. Uses Of Aluminium • Used to make strong, light, corrosion-resistant alloys, which are used in the construction of aeroplanes and ships. • Aluminium is a good conductor of heat and so is used to make saucepans and as a cooking foil. • It is an excellent electrical conductor, and so is used in electricity wires. Recycling of Aluminium • The recycling of aluminium is an economically viable process. • It is also desirable from an environmental point of view, saving energy and conserving natural resources. • When aluminium is being recycled, the aluminium waste is melted. • The impurities are either burned off or separated from the aluminium Anodising • The purpose of anodising is to produce a very hard oxide coating on the surface of aluminium, or one that is very resistant to corrosion. • In anodising, the aluminium is used as an anode in the electrolysis of dilute sulfuric acid. • Graphite, platinum or another inert cathode can be used. Anodising The Aluminium is coated with a thicker layer of aluminium oxide to prevent corrosion. Anode Reaction 2Al +3H2O Al2O3 + 6H+ + 6eCathode Reaction 2H+ + 2e- H2 Manufacture of Iron and Steel Iron is extracted from its ores in a blast furnace. The raw materials are: 1.Iron ore, mainly haematite(Fe2O3) 2.Coke, a form of Carbon 3.Limestone CaCO3 The PROCESS Hot air is blasted through to burn the coke and to form carbon monoxide 1.The coke burns in the furnace to melt the Iron and it makes Carbon Monoxide C + O2 CO2 C + ½ O2 CO 2. The coke reduces the iron oxide 3C + Fe2O3 2Fe + 3CO 3. The Carbon Monoxide also reduces the iron oxide. 3CO + Fe2O3 2Fe + 3CO2 4. The limestone decomposes to lime which reacts with impurities in the ore, mainly SiO2 to form a slag. CaCO3 CaO + CO2 CaO + SiO2 CaSiO3 The Manufacture of Steel Pig iron is changed to steel by • Removing the impurities • Adjusting the amount of carbon The process for making steel is called the basic oxygen steel-making process or BOS process. Oxygen gas is blown through the oxygen lance at high pressure, this reacts with impurities such as carbon and sulphur and oxidises them. These leave as gas (carbon dioxide and sulphur dioxide) and pure iron remains. Calculated amounts of carbon or other metals are added to make a range of different alloys. The Electric Arc method of manufacturing steel.(Video) • Pig iron, scrap iron and lime CaO are added to the furnace. Oxygen is blown through to oxidise the impurities. The lime removes other impurities. Other metals are added depending on the type of steel required. Electric Arc Process The main stages in the process are: 1. Charging the furnace-iron, scrap iron and lime are added to the furnace 2. Melting- large current passed through carbon electrodes to melt the iron. 3. Refining. CaO + SiO2 CaSiO3 (Slag) 4. Tapping-removal of Slag 5. Casting- the steel is molded and cut into required lengths.

![+[1] - franklychemistry.co.uk.](http://s2.studylib.net/store/data/005797611_1-50823830ceb8bfe3d22c2962e03bc5dc-300x300.png)