Non-Ferrous Metals and Alloys

advertisement

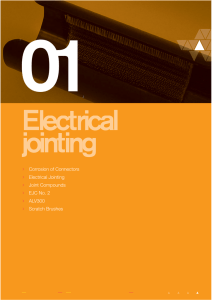

Aluminium A large Aluminium billet from which wrought products will be produced. Aluminium Smelter (Norway) Cast Structure of Al Ingot Boat Hulls Aluminium boat hulls offer corrosion resistance and light weight. XJ6 Aluminium Body XJ6 Aluminium Chassis Aluminium Bumper Beams Aluminium Engine Blocks (Lupo) Audi A2 engine block Aluminium Bottles Aluminium Forging Forged Aluminium Wheels Al heat transfer components Aluminium Roofing Other non-ferrous metals • • • • • • • • Copper Tin Lead Zinc Titanium Lithium Nickel Chromium Copper • • • • • • Moderate strength in the pure state Malleable and ductile Very good electrical and thermal conductor Good corrosion resistance Alloys with Zinc to give brass Alloys with Tin and others to make bronze Copper Roofing Copper as a Biocide Copper as a Heat Exchanger Tin Soft and corrosion resistant. Used to alloy with lead to make solder Used to alloy with copper to produce bronzes, e.g. Bell metal Bell Metal Lead • • • • High Density Corrosion Resistant Malleable, but not ductile Very soft and weak Lead Applications Lead as a Roofing Material Zinc • No structural engineering uses in pure state • Used as sacrificial anodes to protect steel. • Used as an alloy with copper to produce brass • Used to corrosion coat steel by: – Galvanising or – Plating Brass Components Magnesium • Light weight – S.G. of 1.7 • Burns easily when being machined • Used with Aluminium to make lightweight alloys. Magnesium Magnesium Wheel Lithium • Very light, S.G. of 0.5! • Used to make alloys with Aluminium for aerospace applications. • Used in batteries for mobile phones etc. Titanium • Low density (S.G. of 4.5, as compared to steel at approx 8) • Similar strengths to steels • Highly corrosion resistant • Melts at 1670°C • Use restricted to <400 °C Titanium Used in • Aerospace parts • Racing cars, motorcycles and bicycles • Pipework and heat exchangers in chemical plants and oil installations. Titanium heatexchangers Nickel • Corrosion resistant – forms strong oxide layer. • Brittle in the pure state • Used in stainless steels • Alloyed with copper to produce cupronickels for coinage and Monel for corrosion-resistant valve parts. • Used in Nimonic and superalloys for aerospace engine parts. Nickel-based superalloys Single-crystal blades Chromium • Corrosion resistant – forms strong oxide layer. • Brittle in the pure state • Used in stainless steels • Used with Ni & Mo to produce strong steel alloys for bicycle and motorcycle frame tubes.