1. Indust Biotech

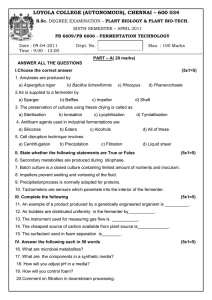

advertisement

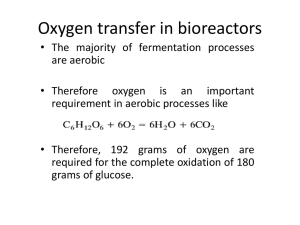

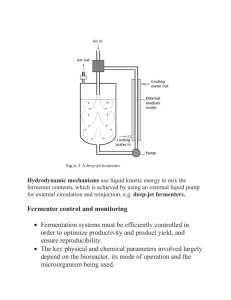

Industrial Biotechnology OLD • Use of micro-organisms for large scale industrial processes • Oldest form of microbiology and biotechnology which was used to make wine, beer, sake, bread with use of bacteria and yeasts without knowing scientific basis • Production of ethanol, lactic acid, butanol using microbes and Enzymes like amylase, protease, invertase were used during early 20th century • Pencillin was produced during WWII and other amino acids, nucleotides, enzymes were also produced later White Biotechnology MODERN • Now use in biotransformations of chemicals, genetic engineering of MO for non microbial products (insulin, interferons, HGH, vaccines) • Microbial Fermentations (organic acids, amino acids, vitamins, antibiotics, enzymes) and fermented foods (dairy, meat, plant, breads, alcoholic beverages) • Use in increase of crop productivity • Biofertilizers and Biopesticides • Use Microbes as food: single cell protein • Bioenergy and Bioremediation • Mining and metallurgy Isolation and culturing Micro-organisms Sources • Soils, lakes, oceans, river, plant, animal, air, non living objects Isolation methods • Serial dilution, spread plate, gradient pour plate, streak plate • Filtration, centrifugation • Importance of eliminating other organisms (antibiotics, heating) Isolation and culturing Micro-organisms Growth Media • MO require nutrients (C, N, requirement, temp, pH, salinity etc • Synthetic media • Semi synthetic media • Natural media P, Minerals), O2 • Media needs to be economical for large scale productions, consistent quality and available throughout. Raw material can be pre-treated if required • Cheap C and N2 sources can be used Isolation and culturing Micro-organisms Sources of nutrition Carbon: sugarcane molasses, beet molasses, vegetable oil, starch, cereal grains, whey, glucose, sucrose, lactose, malt, hydrocarbons Nitrogen: corn steep liquor, slaughter house waste, urea, ammonium salts, nitrate, peanut granules, soyabean meal, yeast extract etc Growth factors: vitamins and amino acids are added when MO cannot synthesize them Isolation and culturing Micro-organisms Sources of nutrition • Trace elements: Zn, Mo, Mn, Cu, Co required for metabolism or in metallo-enzymes or in proteins (Hb) • Inducers, precursors, repressors: for enzymes to function in metabolic processes inducers are required. Sometimes presence of presursors enhances production of a secondary metabolite or production an enzyme can be repressed due to repressors. Eg streptomycin is nduced by yeast extract, Sec metabolites can be repressed due to some cpds. • Antifoams: sunflower oil, olive oil to prevent foaming • Water: clean water of consistent composition, dissolved chemicals, pH is measured. Also required for cleaning, washing, rinsing, cooling, heating etc. Culturing methods for Micro-organisms Sterilization: devoid of MO (aseptic conditions) Contamination free seed culture Sterilization of equipment, media and air Moist heat (121oC/15psi/20min), radiation, ultrasonic treatment, chemicals, mechanical, gases (ozone), filtration for sterilizing air CULTURING Avoidance of contamination can be achieved by • • • • • Use pure inoculum to start fermentation Sterilize the media Sterilize fermenter vessel Sterilize all materials to be added to the fermentation during the process Maintaining aseptic conditions during the fermentation Control of environmental conditions for Microbial growth Temperature pH Agitation O2 conc To be carefully monitored and maintained Acidic pH: fungi and yeast Psychrophiles, acidophiles etc Sterilization: Elimination of threads and welding of pipes and tubes to reduce contamination Fermenters have pipes which flush steam into the system Media along with fermenter is sterilized Among the several factors that influence killing are temperature, pH, osmotic pressure, shear, mass transport, and concentrations of extraneous substances that also react with the killing agent. These factors operate synergistically, and temperature plays roles other than simply affecting the kinetics of a reaction Aeration and Mixing Shake culture: flasks are kept on a shaker for required rotations Fermenters: Stirrers for O2 mixing and baffles for increasing turbulence V shaped notch • Incrs turbulence • Incr eff of O2 transfer • Improves growth of MO Fermentation Fervere: to boil In Microbiology Any process for the production of useful products through mass culture of MO In Biochemistry The numerous O-R reactions in which organic compounds used as carbon and energy act as acceptors and donors of H2 ion. The organic cpd gives rise to various products of fermentation which accumulate in the growth medium Takes place in absence of O2 Now term industrial fermentation for large scale cultivation of microorganisms…most of them is aerobic Bioprocess technology (plants and animal cells) replaces fermentation technology (microbial use)………..not rigid Fermenter or bioreactor • A biorector is a device in which the organisms are cultivated and motivated to form a desired product • Closed vessel or containment designed to give a right environment for optimal growth and metabolic activity of the organism • Fermenter: for microbes/ Bioreactor : for eukaryotic cells • Size variable ranging from 20-250 million litres or more. • Large scale production (10-100L to1000-million L capacity) • Helps to meet requirements of: pH temp aeration agitation drain or overflow control systems sensors cooling to achieve maximum microbial yield What is fermentation technique (1)? Techniques for large-scale production of microbial products. It must both provide an optimum environment for the microbial synthesis of the desired product and be economically feasible on a large scale. They can be divided into surface (emersion) and submersion techniques. The latter may be run in batch, fed batch, continuous reactors In the surface techniques, the microorganisms are cultivated on the surface of a liquid or solid substrate. These techniques are very complicated and rarely used in industry What is fermentation technique (2)? In the submersion processes, the microorganisms grow in a liquid medium. Except in traditional beer and wine fermentation, the medium is held in fermenters and stirred to obtain a homogeneous distribution of cells and medium. Most processes are aerobic, and for these the medium must be vigorously aerated. All important industrial processes (production of biomass and protein, antibiotics, enzymes and sewage treatment) are carried out by submersion processes. Some important fermentation products Product Ethanol Glycerol Lactic acid Acetone and butanol -amylase Organism Saccharomyces cerevisiae Saccharomyces cerevisiae Lactobacillus bulgaricus Clostridium acetobutylicum Bacillus subtilis Use Industrial solvents, beverages Production of explosives Food and pharmaceutical Solvents Starch hydrolysis Some important fermentation products 16 Some important fermentation products Some important fermentation products Winemaking fermenter 19 General Aspects of Fermentation Processes Fermenter The heart of the fermentation process is the fermenter. In general: • Stirred vessel, H/D 3 • Volume 1-1000 m3 (80 % filled) • Biomass up to 100 kg dry weight/m3 • Product 10 mg/l –200 g/l Component parts of a fermenter 1. Formulation of media to be used in culturing the organism during development of inoculum and in the production fermenter 2. Sterilization of the medium, fermenter and ancillary equipment 3. Production of an active, pure culture in sufficient quantity to inoculate the production vessel 4. The growth of the organism in the production fermenter under optimum conditions for product formation 5. The extraction of the product and its purification 6. Disposal of effluents produced by the process Production fermenter Stock culture Shake flask Biomass Culture fluid Seed fermenter Cell separation Cell free supernatant Medium STERILIZATION Medium FORMULATION Medium raw material Product purification Product packaging Product extraction Effluent treatment DOWNSTREAM PROCESSING Cross section of a fermenter for Penicillin production ( Copyright: http://web.ukonline.co.uk/webwise/spinneret/microbes/penici.htm) Cross section of a fermenter for Penicillin production ( Copyright: http://web.ukonline.co.uk/webwise/spinneret/microbes/penici.htm) 25 Flow sheet of a multipurpose fermenter and its auxiliary equipment Basic modes of operations of a fermenter 1. Batch culture Batch fermentation refers to • a partially closed system in which most of the materials required are loaded onto the fermentor, decontaminated before the process starts and then, removed at the end. • The only material added and removed during the course of a batch fermentation is the gas exchange and pH control solutions. • In this mode of operation, conditions are continuously changing with time, and the fermentor is an unsteady-state system, although in a well-mixed reactor, conditions are supposed to be uniform throughout the reactor at any instant time. The principal disadvantage of batch processing is the high proportion of unproductive time (down-time) between batches, comprising the charge and discharge of the fermenter vessel, the cleaning, sterilization and re-start process Basic modes of operations of a fermenter 2. Continuous culture Continuous culture is a technique involving feeding the microorganism used for the fermentation with fresh nutrients and, at the same time, removing spent medium plus cells from the system A unique feature of the continuous culture is that a timeindependent steady-state can be attained which enables one to determine the relations between microbial behavior (genetic and phenotypic expression) and the environmental conditions. Basic modes of operations of a fermenter 3. Fed-batch processes The fed-batch technique was originally devised by yeast producers in the early 1900s to regulate the growth in batch culture of Saccharomyces Yeast producers observed that in the presence of high concentrations of malt, a by-product - ethanol - was produced, while in low concentrations of malt, the yeast growth was restricted. The problem was then solved by a controlled feeding regime, so that yeast growth remained substrate limited. The concept was then extended to the production of other products, such as some enzymes, antibiotics, growth hormones, microbial cells, vitamins, amino acids and other organic acids. 3. Fed-batch processes Basically, cells are grown under a batch regime for some time, usually until close to the end of the exponential growth phase. At this point, the reactor is fed with a solution of substrates, without the removal of culture fluid. This feed should be balanced enough to keep the growth of the microorganisms at a desired specific growth rate and reducing simultaneously the production of by-products (that can be growth or product production inhibitory and make the system not as effective). By products may lead to cell death A fed-batch is useful in achieving high concentration of products as a result of high concentration of cells for a relative large span of time. Two cases can be considered: the production of a growth associated product and the production of a non-growth associated product. In the first case, it is desirable to extend the growth phase as much as possible, minimizing the changes in the fermenter as far as specific growth rate, production of the product of interest and avoiding the production of by-products. For non-growth associated products, the fed-batch would be having two phases: a growth phase in which the cells are grown to the required concentration and then a production phase in which carbon source and other requirements for production are fed to the fermenter. This case is also of particular interest for recombinant inducible systems: the cells are grown to high concentrations and then induced to express the recombinant product Types of Bioreactors • • • • • • • • Simple fermenters (batch and continuous) Fed batch fermenter Air-lift or bubble fermenter Cyclone column fermenter Tower fermenter Fluidized bed bioreactors Packed bed bioreactor photobioreactor • Other more advanced systems, etc The size is few liters (laboratory use) - >500 m3 (industrial applications)