Ethanol_17nov - aos-hci-2012-research

advertisement

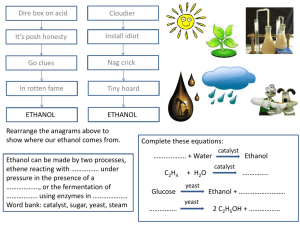

Done by: Aman Mangalmurti Kara Newman Leong Qi Dong Soh Han Wei Rationale Depletion of nonrenewable fossil fuels due to excessive consumption as a source of energy Conversion of renewable sources, e.g. organic wastes, to fuel ensures continual energy supply Potential for producing ethanol from fruit peel wastes through fermentation by microorganisms Ethanol as a renewable, alternative energy source Rationale Heavy metal water contamination of water is rampant in many countries. Heavy metal ions accumulate inside organisms and cause adverse health effects Biosorption in removal of heavy metal ions by fruit peel wastes Literature Review Demand for renewable energy resources has increased due to increased prices for oil and concerns about global warming (Wilkins , Widmer & Grohmann, 2007) Production of ethanol by Saccharomyces cerevisiae from Mango fruit processing solid and liquid wastes (Reddy, Reddy & Wee, 2011) Pineapple waste (Hossain & Fazliny, 2010) Literature Review Industries such as electroplating, mining and paint contribute to heavy metal pollution in the ambient environment Heavy metal ions that pollute water include antimony, copper, lead, mercury, arsenic and cadmium (US Environmental Protection Agency, 2011) Methods of removal of ions include chemical precipitation and solvent extraction Expensive and low efficiency at low metal ion concentrations Objectives To prepare extracts of fruit peel for ethanol fermentation To determine which fruit peel gives highest ethanol yield from the fermentation of fruit peel extract To determine which fruit peel waste gives rise to maximal adsorption of heavy metal ions of Cu2+,Cu3+ ions Hypothesis Ethanol yield from fermentation of the banana peel would be higher than that of the mango peel Zymomonas mobilis produces more ethanol during fermentation as compared to Saccharomyces cerevisiae The mango peel would adsorb heavy metal ions better as compared to banana peels Experimental outline Preparation of fruit peel extract First ethanol fermentation Heavy metal ion adsorption for Copper(II), Copper (III) ions Second ethanol fermentation after treatment of peel residue with cellulase Variables Constant Independent Dependent • Temperature of growth of organisms (30C) • Initial concentration of heavy metal ions (50 ppm) • Fruit peels used (AOS: banana, HCI: mango) • Organism used (S. cerevisiae, Z. mobilis) • Heavy metal ions (Cu2+ ,Cu4+) • Initial concentration of reducing sugars in fruit peel extracts • Ratio of ethanol yield to initial sugar concentration • Final ethanol yield • Final concentration of heavy metal ions Apparatus & Materials Apparatus Blender Sieve Boiling water bath Spectrophotometer cuvettes Spectrophotometer Centrifuge Glass rod Hot Plate Incubator Dropper Sieve: 0.25mm (60 Mesh) Shaking incubator Fractional distillator Test tubes Filter funnel Filter paper Beaker Volumetric Flask Colorimeter Quincy Lab Model 30 GC hot-air oven Measuring cylinder Magnetic stirrer Rotary mill Materials Mango Peel Banana Peel Deionised water Dinitrosalicylic acid (DNS acid) Zymomonas mobilis Saccharyomyces cerevisiae Glucose-yeast medium (Yeast malt extract broth) sodium alginate medium calcium chloride solution sodium chloride solution acidified potassium chromate solution Cu2+ ion solution Cu4+ ion solution MgSO4∙7H2O 0.1 and (magnesium sulfide hydrate) KH2PO4 0.1 (potassium phosphate) cellulase Extraction of sugars from fruit peels 30 g of fruit peels are blended in 300 ml of deionised water using a blender. The liquid is passed through a sieve to remove the residue. Determination of sugars in extracts To 0.5 ml of extract, 0.5 ml of DNS (dinitrosalicylic acid) is added. The concentration of reducing sugars in μmol/ml is read from a maltose standard curve. The mixture is left in a boiling water bath for 5 minutes. 4 ml of water is then added. The samples are placed in spectrophotometer cuvettes and the absorbance is taken at 530 nm using a spectrophotometer. Growth of Z. mobilis Z. mobilis cells are inoculated in 20 ml GY medium (2% glucose, 0.5% yeast extract) and incubated at 30°C for 2 days with shaking. Immobilisation of cells The Z. mobilis preculture and S. cerevisiae preculture are centrifuged at 7000 rpm for 10 minutes and the cell pellets are resuspended in 7.5 ml of fresh GY medium. The beads are rinsed with 0.85% sodium chloride solution. The absorbance of the cultures are taken at 600 nm. 7.5 ml of 2% sodium alginate is added to the cell suspension and mixed well. The mixture is dropped into 0.1 mol dm‐3 calcium chloride solution to form Z. mobilis alginate beads. Growth of S. cerevisiae S. cerevisiae cells are inoculated in 50 ml YM broth medium with the pH adjusted to 5.6 and incubated at 35°C for 1 days with shaking, before being concentrated in a refrigerated centrifuge at 10, 000 rpm. Ethanol fermentation by immobilized Z. mobilis cells 200 beads are added to 50 ml waste extract. A control is prepared in which 200 empty alginate beads are added to the same volume of waste extract instead. All the set‐ups are incubated with shaking at 30°C for 2 days for ethanol fermentation to occur. The beads are then removed and the extracts are distilled to obtain ethanol. Ethanol fermentation by S. cerisiae To be added Back Determination of ethanol yield with the dichromate test 2.5 ml of acidified potassium dichromate solution is added to 0.5 ml of distillate in a ratio of 5:1. The samples are placed in a boiling water bath for 15 minutes. The absorbance is measured at 590 nm using a spectrophotometer, and the concentration of ethanol is read from an ethanol standard curve. Adsorption of heavy metal ions Desiccate fruit peel residue, (put the residue in the hot air oven and dry them at 60 degrees for 23 hours) Repeat for Cu4+ Using a rotary mill to grind desiccated residue Allow solution to set for 20 min, preferably at 100rpm to increase contact time Sieve to 0.25 mm particle size. Add residue powder to 50ppm Cu2+ solution. Determination of final ion concentration Allow solution to set for 20 min, preferably at 100rpm to increase contact time Remove fruit product, by filtering the suspension Using a copper reagent, the remaining concentration of copper ions will be found Treatment of residue with cellulase Fruit peel particles are added into the beaker. The beaker is drained and fruit peel is left to dry. 25ml of cellulase is added to the beaker. 50 ml water is added to beaker Beaker is left standing for 1 hour with continuous stirring. Second ethanol fermentation Identical to above Ethanol fermentation Determination of final ethanol yield 2.5 ml of acidified potassium dichromate solution is added to 0.5 ml of distillate in a ratio of 5:1. The samples are placed in a boiling water bath for 15 minutes. The absorbance is measured at 590 nm using a spectrophotometer, and the concentration of ethanol is read from an ethanol standard curve. Applications Cost-effective method of producing ethanol Reduces reliance on non-renewable fossil fuels Recycles fruit peels Viable method in wastewater treatment Timeline Finalizing of project details 12-23 Nov 1st round of experiments 7 Dec - Mar 2nd round of experiments Mar - May Final round of experiments and Data Analysis May Jul Bibliography Anhwange, T. J. Ugye, T.D. Nyiaatagher (2009). Chemical composition of Musa sapientum (Banana) peels. Electronic Journal of Environmental, Agricultural and Food Chemistry, 8, 437-442 Retrieved on 29 October 2011 from: http://ejeafche.uvigo.es/component/option,com_docman/task,doc_view/gid,495 Björklund, G. Burke, J. Foster, S. Rast, W. Vallée, D. Van der Hoek, W. (2009, February 16). Impacts of water use on water systems and the environment (United Nations World Water Development Report 3). Retrieved June 6, 2011, from www.unesco.org/water/wwap/wwdr/wwdr3/pdf/19_WWDR3_ch_8.pdf US Environmental Protection Agency (2011) .Drinking Water Contaminants. Retrieved June 6, 2011, From http://water.epa.gov/drink/contaminants/index.cfm Mark R. Wilkins , Wilbur W. Widmer, Karel Grohmann (2007). Simultaneous saccharification and fermentation of citrus peel waste by Saccharomyces cerevisiae to produce ethanol. Process Biochemistry, 42, 1614–1619. Retrieved on 29 October 2011 from: http://ddr.nal.usda.gov/bitstream/10113/16371/1/IND44068998.pdf References Hossain, A.B.M.S. & Fazliny, A.R. (2010). Creation of alternative energy by bio‐ethanol production from pineapple waste and the usage of its properties for engine. African Journal of Microbiology Research, 4(9), 813‐819. Retrieved October 27, 2011 from http://www.academicjournals.org/ajmr/PDF/Pdf2010/4May/Hossain%20and%20Fazliny.pdf Mishra, V., Balomajumder, C. & Agarwal, V.K. (2010). Biosorption of Zn(II) onto the surface of non‐living biomasses: a comparative study of adsorbent particle size and removal capacity of three different biomasses. Water Air Soil Pollution, 211, 489‐500. Retrieved October 27, 2011 from http://www.springerlink.com/content/2028u2q551416871/fulltext.pdf Tanaka, K., Hilary, Z.D. & Ishizaki, A. (1999). Investigation of the utility of pineapple juice and pineapple waste material as low‐cost substrate for ethanol fermentation by Zymomonas mobilis. Journal of Bioscience and Bioengineering, 87(5), 642‐646. Ban‐Koffi, L. & Han, Y.W. (1990). Alcohol production from pineapple waste. World Journal of Microbiology and Biotechnology, 6(3), 281‐284. Reddy, L.V., Reddy, O.V.S. & Wee, Y.‐J. (2011). Production of ethanol from mango (Mangifera indica L.) peel by Saccharomyces cerevisiae CFTRI101. African Journal of Biotechnology, 10(20), 4183‐4189. Retrieved October 27, 2011 from http://www.academicjournals.org/AJB/PDF/pdf2011/16May/Reddy%20et%20al.pdf Isitua, C.C. & Ibeh, I.N. (2010). Novel method of wine production from banana (Musa acuminata) and pineapple (Ananas comosus) wastes. African Journal of Biotechnology, 9(44), 7521‐7524. Nigam, J.N. (2000). Continuous ethanol production from pineapple cannery waste using immobilized yeast cells. Journal of Biotechnology, 80(2), 189‐193. Saccharomyces cerevisiae ATCC 24553 immobilised in k‐carrageenan