Gravimetric Analysis Principles: A Chemistry Presentation

advertisement

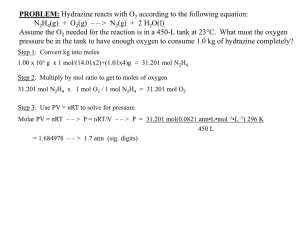

PRINCIPLE OF GRAVIMETRIC ANALYSIS GROUP 1 :MIC 3A1 GRAVIMETRIC ANALYSIS Gravimetric analysis is one of the most accurate and precise method of macroquantitative (large quantity) analysis. In this process the analyte is selectively converted into insoluble form STEPS IN A GRAVIMETRIC ANALYSIS PREPARARION OF THE SOLUTION PRECIPITATION DIGESTION FILTERATION WASHING DRYING AND IGNITING CALCULATION PREPARING OF THE SOLUTION Factor that must considered during prepararion of solution : 1. 2. 3. 4. 5. Volume of the solution during precipitation The concentration range of the test substance The presence and concentration of other constituents Temperature pH Some form of preliminary separation may be necessary to eliminate interfering material. Adjust the solution condition to maintain low solubility of the precipitate and to obtain it in a form suitable for filtration. Proper adjustment of the solution conditions prior to precipitation may also mask potential interferences. pH is important because it often influences both the solubility of the analytical precipitate and the possibility of interferences from other substances. PRECIPITATION Important conditions of substance that must be taken into account before conducting precipitation: The precipitate should first be sufficiently insoluble that the amount lost due to solubility will be negligible. It should consist of consist of large crystals that can be easily filtered. All precipitates tend to carry some of other constituents of the solution with them. This contamination should be negligible. Keeping the crystals large can minimize this contamination. PRECIPITATION PROCESS: After adding precipating agent such as AgNO3 ,precipitation occur but in series(step by step) 1. 2. SUPERSATURATION-The solution phase contain more of the dissolved salt than occurs at equilibrium. NUCLEATION A minimum number of partical must come together to produce microscopic nuclei of the solid phase. The higher the degree of supersaturation the greater the rate of nucleation. Von Weimarn ratio: Relativesupersaturation Q -S S •Q - degree of supersaturation(the concentration of the mixed reagent before precipitation occur) •S - solubility of the precipitate at equilibrium High relative supersaturation- many small crystal (high surface area) Low relative supersaturation- fewer, larger crystal (low surface area) STEPS TO MAINTAIN FAVOURABLE CONDITIONS FOR PRECIPITATIONS 1. 2. 3. 4. Precipitate from dilute solution. This keeps Q low. Add dilute precipitating reagents slowly, with effective stirring. This also keeps Q low. Stirring prevents local excesses of the reagent. Precipitate from hot solution. This increase S. the solubility should not be too great or the precipitation will not be quantitative (with less than 1 part per thousand remaining). The bulk of the precipitation maybe performed in the hot solution, and then the solution may be cooled to make the precipitation quantitative. Precipitate at as low a pH as is possible to maintain quantitative precipitation. As we have seen, many precipitates are more soluble in acid medium, and this slows the rate of precipitation. They are more soluble because the anion of the precipitate combines with protons in the solution. DIGESTION To make precipitate become larger and more pure crystals. Also known as Ostwald ripening (digestion). Ostwald ripening improves the purity and crystallinity of the precipitate. In digestion, colloidal particles formed counter layer(secondary layer) , primary absorptive layer and colloidal(large number of small particle) AgCl. There are 2 types of colloidal particles which is hydrophilic and hydrophobic. FILTRATION(IMPURITIES IN PRECIPITATE) Precipitates tend to carry down from the solution other constituents, causing the precipitate to become contaminated. This process of contamination is called coprecipitation. Ways in which a foreign material may be coprecipitate. OCCLUSION AND INCLUSION. 1. o o o In the process of occlusion, material that is not part of the crystal structure is trapped within a crystal. For example, water may be trapped in pockets when AgNO3 crystals are formed, and this can be driven off by melting. Inclusion occurs when ions, generally of similar size and charge, are trapped within the crystal lattice (isomorphous inclusion, as with K+ in NH4MgPO4 precipitation). 2. SURFACE ADSORPTION The surface of the precipitate will have a primary adsorbed layer of the lattice ions in excess. For example, after the barium sulfate is completely precipitated, the lattice ion in excess will be barium, and this will form the primary layer. Digestion reduces the surface area and the amount of adsorption. Surface adsorption of impurities is the most common source of error in gravimetry. It is reduced by proper precipitation technique, digestion, and washing. 3. ISOMORPHOUS REPLACEMENT Two compound are said to be isomorphous if they have same type of formula and crystallize in similar geometric forms. When the lattice dimensions are about the same, one ions can replace another in the crystal, resulting in a mixed crystal. For example, in the precipitation of Mg2+ as magnesium ammonium phosphate, K+ has nearly the same ionic size as NH4+ and can replace it to form magnesium potassium phosphate. It is very serios and little can be done about it,so precipitates in which it occurs are seldom used analytically. 4. POSTPRECIPITATION. When the precipitate is allowed to stand in contact with the mother liquor(the solution from it was precipitate), a second substance will slowly form a precipitate with the precipitating regent. For example, when calcium oxalate is precipitated in the presence of magnesium ions, magnesium oxalate does not immediately precipitate because it tends to form supersaturated solutions. It will come down if the solution is allowed to stand too long before being filtered. WASHING Coprecipitated impurities, especially those on the surface, can be removed by washing the precipitate after filtering. The precipitate will be wet with the mother liquor, which is also removed by washing. Many precipitates cannot be washed with pure water, because peptization(washing particles with water increases the extend of solvent/water moleculer between the layers, causing the secondary layer to be loosely bound,the particles revert to colloidal state) occurs. This is the reverse of coagulation Coagulated particles have a neutral layer of adsorbed primary and counterions. presence of another electrolyte will cause the counterions(an ion having a charge opposite to that of the substance with which is associated). These foreign ions are carried along in the coagulation. Washing with water will dilute and remove foreign ions, and the counterion will occupy a larger volume, with more solvent molecules between it and the primary layer. The repulsive forces between particles between particles become strong again, and the particles partially revert to the colloidal state and pass through the filter. This can be prevented by adding an electrolyte to the wash liquid. Eg: HNO3 or NH4NO3 for AgCl precipitate. DRYING OR IGNITING This process is to removes the solvent and wash electrolytes. If the collected precipitate is in a form suitable for weighing, it must be heated to remove the water and the absorbed electrolyte from the wash liquid. The preferable temperature use for drying is by drying it at 110°C to 120°C for 1 or 2 hours. Ignition at a higher temperature are required if a precipitate must be converted to a more suitable form for weighing. CALCULATION Gravimetric factor(GF)-the weight of analyte per unit weight of precipitate f wt analyte(g/mol) a GF (molanalyte/mol precipitate) f wt precipitate (g /mol) b g analyte/gprecipitate So, if Cl2 in a sample is converted to chloride and precipitated as AgCl, the weight of Cl2 that gives 1 g of AgCl is f wt Cl2 (g Cl2/molCl2) 1 g Cl2 g AgCl (molCl2/mol AgCl) f wt AgCl (g AgCl/molAgCl ) 2 g AgCl GF (g Cl2/g AgCl) g AgCl 0.24737 (g Cl2/g AgCl) EXAMPLE 1 CALCULATE THE GRAMS OF ANALYTE PER GRAM OF PRECIPITATE FOR THE FOLLOWING CONVERSION: Analyte Precipitate P Ag3PO4 K2HPO4 Ag3PO4 Bi2s3 3BaSO4 Solution at wt P (g/mol) 1 ( mol P /mol Ag3P O4) g wt Ag3P O4 (g/mol) 1 30.97(g P /mol) 1 418.58( g Ag3P O4/mol) 1 0.07399g P /g Ag3P O4 GF g P /g Ag3P O4 f wt K2HP O4 (g/mol) 1 (mol K2HP O4/mol Ag3P O4) f wt Ag3P O4 (g/mol) 1 174.18(g K2HP O4(g/mol ) 1 418.58( g Ag3P O4/mol) 1 0.41612g K2HP O4/g Ag3P O4 GF g K2HP O4/g Ag3P O4 f wt Bi2S3 (g/mol) 1 g Bi2S3/g BaSO4 (mol Bi2S3/mol BaSO4) f wt BaSO4 (g/mol) 3 514.15 (g Bi2S3/mol) 1 233.40(g BaSO4) 3 0.73429g Bi2S3/g BaSO4 GF •In order to calculate the percent composition by weight of analyte in the sample, the weight of substance sought was divided with the weight of sample and times with 100%. •The weight of sample sought can be obtain from the weight of precipitate and the corresponding weight/mole relationship, as in equation below: weightof substancesought(g) weightof precipitate(g) f wt substancesought(g/mol) f wt precipitate (g/mol) a ( mol substancesought/molprecipitate) b weightof precipitate (g) GF (g sought/gprecippitate) •Thus, the general formula would be: % sought weightof precipitate (g) GF (g sought/gprecipitate) 100% weightof sample (g) EXAMPLE 2 An ore is analyzed for the manganese content by converting the manganese to Mn3O4 and weighing it. If a 1.52g sample yeilds Mn3O4 weighing 0.126g,what would be the percent Mn2O3 in the sample? The percent Mn? Solution 3Mn2O3 (g Mn2O3 / g Mn3O4) 2Mn3O4 % Mn2O3 100% 1.52g sample 0.126g 3(157.9)/2(228.8) 100% 8.58% 1.52 g 0.126g Mn3O4 3Mn ( g Mn/ g Mn3O4) Mn3O4 % Mn 100% 1.52 g sample 0.126g 3(54.94)/228.8 100% 5.97% 1.52 g 0.126g Mn3O4 EXAMPLE 3: What weight of pyrite ore (impure FeS2 ) must be taken for analysis so that the BaSO 4 precipitate weight obtained will be equal to one-half that of the percent S in the sample? Solution: gA 100% g sample 1 S A(g BaSO4) (g S/g BaSO4) BaSO4 A %S 2 100% g sample 1 32.064 1% S 2 233.40 100% g sample g sample 6.869g %A THE END….