Selection of polymers

advertisement

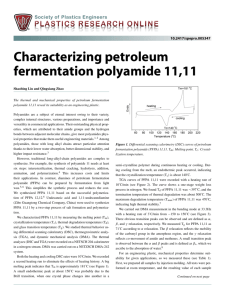

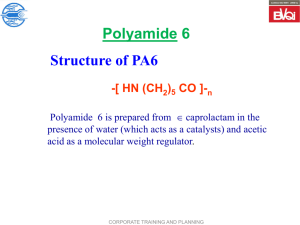

Lesson 5 2014 Lesson 5 2014 Our goal is, that after this lesson, students are able to recognize the key criteria for selecting polymers and are able to use different tools to support the systematic material selection process for proper selection of polymers. Special material properties Viewpoints of Chemistry Selection of Polymers Tools for systematic selection Temperature related selection criteria Special materials properties affecting to proper selection of polymers: • • • • 1. Glass transition temperature 2. Shape of the stress-strain curve 3. Viscoelastic behavior 4. Creeping strength and heat deflection temperature • 5. Fatigue strength and grazing • 6. Impact strength and brittleness temperature • 7. Ageing -sunlight, chemicals • 8 .Stress cracking - residual stresses due to manufacturing - environmental reasons (e.g. some chemicals) Fracture mechanisms of polymers Both ductile and brittle fracture are possible. Brittle fracture is favored at lower temperatures, higher strain rates, and at stress concentrators Brittle to ductile transition often occurs with increasing temperature The third “fracture mechanism is called “crazing “… Crazing occurs when localized regions yield, forming microvoids inside polymer chain structure. Fibrillar bridges or fibrils are formed around and between voids. Crazing absorbs fracture energy and increases fracture toughness Strain Strain Microvoids Fibrils in polymer chains Microvoids Fibrils in polymer chains Stress [MPa] Viscoelasticity: Viscoelastic behavior is determined by rate of strain: elastic for rapidly applied stress, viscous for slowly applied stress! Ultimate tensile strength Yeld strength Relative elongation [%] Linear or nonlinear plastic deformation Reduction of the crosssection area Plastic deformation POLYMERS POLYMERIZATION ADDITION POLYMERIZATION CHARACTERISTICS OF POLYMERS (TYPES) THERMOPLASTIC THERMOSEPTIC CONDENSATION POLYMERIZATION ELASTOMERS TYPES OF POLYMERCHAINS CARBONHYDROGEN POLYMERS (PE) CARBON-CHAIN POLYMERS (PTFE) HETEROCHAIN POLYMERS (PA) AMIDI-GROUP POLYMER CONSTRUCTIONS WITH THE AROMATIC RINGS IN THE CHAIN (Kevlar) Polymerization • 1. Addition is a chain-reaction, where monomer units are attached one at a time. E.g. PVC. • 2. Condensation is a step reaction, which produce the mer units. Usually there is small by-product that is later eliminated. E.g. PA. • Note: Polymers manufactured with condensation polymerization absorb easily water, which can damage their structure relatively soon! Effects of the chemical structure on the polymers` properties Structure and bonding of mers Molecular structure Single bonded (c-c) Stereo isometric forms Construction of the polymer chain LINEAR BRANCHED Double bonded (c=c) Aromatic rings TACTICITY Isotactic Syndiotactic Heterotactic Atactic Eutactic CROSSLINKED DENSITY Lowdensity LD Highdensity HD Mediumdensity MD Linear lowdensity LDD Ultra highmolecular weight (UHMW) Number of monomers Copolymers Homopolymers AFFECTS OF BONDING BETWEEN MERS Bonding between the atoms Bonding energy kJ/mol C-C 350 C-H 410 C-F 440 C-Cl 330 C-O 350 C-S 260 C-N 290 N-N 160 N-H 390 O-H 460 C=C 810 C=O 715 C=N 615 O OH H N AROMATIC RING H N O H CHEMICAL STRUCTURE OF KEVLAR n AFFECTS OF STEREOISOMETRIC FORMS (TACTICITY) METHYLENE GROUPS CH3 CH3 CH3 CH3 CH3 CH3 HIGH STRENGTH OF THE STRUCTURE METHYLENE GROUPS CH3 CH3 CH3 HIGH STIFFNESS AND RIGIDITY OF THE STRUCTURE METHYLENE GROUPS CH3 CH3 CH3 AFFECTS OF DENSITY Density classification Property LDPE LLDPE HDPE Mass (g/cm³) 0,920,93 0,9220,926 0,950,96 Tensile strenght (GPa) 6,2-17,3 12,4-20,0 Elongnation to rupture % 550-600 600-800 20,037,3 20-120 HDPE LDPE LLDPE STRENGHT INCREASES Ultra high-performance polymers High-performance polymers Engineering polymers PEEK PAI PTFE, PPA PPS, PFA General polymers PET, POM ,PA PP ,PE Semicrystalline polymers Maximum operating temperature Minimum operating temperature Required temperature during the manufacturing process Melting point Decomposition temperature of the polymer chain Polymer degradation due to overheating Glass transition temperature ASPECTS AFFECTING THE CRITICAL TEMPERATURE OF POLYMERS Viscoelastic behavior related to temperature and impact forces Brittleness temperature Creeping strength at the specific temperature Heat deflection temperature (load is specified) Fatigue strength at the specific temperature Modulus of elasticity of polymers depending on temperature E (Modulus of elasticity) Viscoelasticity : - glass at low temperatures - rubber at intermediate temperatures - viscous liquid at high temperatures. Rigid state Glassy state Viscoelastic behavior is determined by rate of strain (elastic for rapidly applied stress, viscous for slowly applied stress) Leathery state Rubbery flow Liquid flow Tglass transition Tmelting T (Temperature) Examples of glass transition temperatures for some polymers GREEPING STRENGTH Many polymers susceptible to time-dependent deformation under constant load – viscoelastic creep Creep may be significant even at room temperature and under moderately low stresses (below yield strength). STRESS [MPa) TEMPERATURE 23ºC 70ºC 100ºC 1 100 10000 TIME NEEDED TO FRACTURE [h] Polymer Heat deflection temperature °C (under 1.8 MPa loading) Polyethylene (UHDPE) 40 Polypropylene (PP) 60 Polyamide (PA6,6 + nylon) 90 Polyamide-imide (PAI) 280 UTILIZATION OF FOUR-FIELD ANALYSIS FOR POLYMERS’ SELECTION ULTIMATE TENSILE STRENGTH PC+ glass-fiber PI Rejected area PC MAX. OPERATING TEMPERATURE MIN. OPERATING TEMPERATURE PI PC+ glass-fiber PC IMPACT STRENGTH UTILIZATION OF FOUR-FIELD ANALYSIS FOR POLYMERS’ SELECTION RESISTANCE AGAINST ACID AGENTS PTFE PTFE PI PI Required area 1 WATER ABSORBTION PI RESISTANCE AGAINST ORGANIC SOLVENTS PI PTFE PTFE RESISTANCE AGAINST ALCALINE AGENTS UTILIZATION OFCOBWEB-ANALYSIS FOR POLYMERS’ SELECTION WEAR RESISTANCE 1A Accepted area 3A 3C Required wear resistance 2B 2A 1B COMPRESSION STRENGTH Required strength COMPARISON TABLE TO FIT THE MATERIAL PROBERTIES WITH REQUIREMENTS Polymer Option 1 Option 2 Option 3 Option 4 Max. / Min. operating temperature [ °C] / [ °C] Glass deformation temperature [ °C] Heat deflection temperature [ °C] Brittleness temperature [ °C] Creeping strength at X °C [MPa] Required range: [ °C] / [ °C] Affecting load: [ MPa / °C] Material property: [ °C] / [ °C] Material property: [ MPa] / °C] Required range: [ °C] / [ °C] Affecting load: [ MPa / °C] Material property: [ °C] / [ °C] Material property: [ MPa] / °C] Required range: [ °C] / [ °C] Affecting load: [ MPa / °C] Material property: [ °C] / [ °C] Material property: [ MPa] / °C] Required range: [ °C] / [ °C] Affecting load: [ MPa / °C] Material property: [ °C] / [ °C] Material property: [ MPa] / °C] Processing temperature [ °C] Energy costs: [€] Energy costs: [€] Energy costs: [€] Energy costs: [€] Amide group PA Polyamide (Nylon) - Minlon® PA - Zytel® PA PA 11 Polyamide 11 PA 12 Polyamide 12 PA 46 Polyamide 46 PA 6 Polyamide 6 PA 6 / 12 Polyamide 6 / Polyamide 12 PA 6 / 66 Polyamide 6 / Polyamide 66 PA 6 / 69 Polyamide 6 / Polyamide 69 PA 6 / 6T Polyamide 6 / Polyamide 6t PA 610 Polyamide 610 PA 612 Polyamide 612 PA 6-3-T Polytrimethylene Hexamethylene Terephthalamide PA 66 Polyamide 66 - Minlon® PA - Zytel® PA PA 66 / 6 Polyamide 66 / Polyamide 6 - Zytel® PA PA 66 / 610 Polyamide 66 / Polyamide 610 PA 68 Polyamide 68 - Minlon® PA - Zytel® PA -Zytel® PA HDPE High Density Polyethylene - Rigidex® Polyethylene - Eraclene® LDPE - TIPELIN® HDPE LDPE Low Density Polyethylene - INEOS LDPE - Riblene® LDPE - Borstar Polyolefin - Ipethene® LDPE - TIPOLEN® LDPE LLDPE Linear Low Density Polyethylene PEHD High-Density Polyethylene - Eraclene® HDPE - ExxonMobil™ HDPE - Rigidex® Polyethylene - TIPELIN® HDPE UHMWPE Ultrahigh Molecular Weight Polyethylene ULDPE Ultra Low Density Polyethylene -Clearflex® LLDPE Applications from mechanical engineerig: Polymer gears: High Performance Polymers (PEEK,PES,PI) Harsh loading conditions Polyasetal POM Good fatigue strength Polyamide PA Good adhesive wear resistance Phenol polymers, e.g. PF Cost-effectiveness Sliding bearings: Polyamide PA, Polyethylene PE, Teflon (small friction coefficient with adjacent steel components) The properties of polymers can be improved by reinforcing the matrix (carbon, aramid or other fibers) or by surface treatments (e.g. MoS2) Remember the manufacturability aspects! Polymer Shrinkage during extrusion into mold %