C8 & C9 - uaschemistry

advertisement

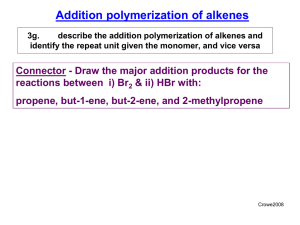

Chemistry Presentation C8 – Condensation polymers C9 – Mechanisms in the organic chemicals industry Seunghwan Lee C.8.1 • Distinguish between addition and condensation polymers in terms of their structures. Addition polymers Polyethene Polychloroethene Polytetrafluoroethene Condensation polymers C.8.2 • Describe how condensation polymers are formed from their monomers. Phenol-methanal plastics • Phenol-methanal plastics are made by adding acid or alkali to a mixture of phenol and methanal. The methanal is first substituted in the 2- or 4- position in the phenol and then the product undergoes a condensation reaction with another molecule of phenol with the elimination of water Polyurethane • Polyurethanes are produced from the reaction of polyhydric alcohols (e.g. diols or triols) with compounds containing more than one isocyanate functional group, -NCO. Polyethylene terephthalate (PET) • Benzene-1,4-dicarboxylic acid + ethane-1,2diol. PET is famous for beverage container, too. C.8.3 • Describe and explain how the properties of polymers depend on their structural features. Cross-linking sturcture of a phenolmethanal plastic • This structure makes the bonds stronger and the melting point higher. In fact, it has such a high melting point that it decomposes before melting. It is also very unreactive. • Due to its high electrical resistance it was used as the casing for early radios and is now used as one of the ingredients in worktops and printed circuit-board insulation. Kevlar • Kevlar is a polyamide made by condensing 1,4diaminobenzene with benzene-1,4-dicarbonyl chloride. • It forms a strong three-dimensional structure due to hydrogen bonding between the long rigid chains. Kevlar C.8.4 • Describe ways of modifying the properties of polymers. Examples • Air can be blown into polyurethanes to make polyurethane foams for use as cushions and thermal insulation. • The fibers of polyesters can be blended with other manufactured or natural fibers for making clothes which are dye-fast and more comfortable than pure polyesters. Examples (cont.) • When ethyne is polymerized the cis- form of poly(ethyne) is found to be an electrical conductor due to the delocalization of the π electrons. Doping • The conductivity can be dramatically increased by adding chemicals such as iodine which can remove electrons or alkali metals which can add electrons. This process is known as doping. C.8.5 • Discuss the advantages and disadvantages of polymer use. Advantages • Strength: Polymers, such as Kevlar, are so strong that they are commonly used to make bullet proof armor. • Density: Compared to metals, polymers are much lighter yet strong. • Durability: Polymers hardly corrodes or oxidize. • Insulation: Some polymers are good insulators. • Conductivity: Some polymers are good conductors. • Lack of reactivity: Polymers do not tend to react with other elements. Disadvantages • Disposal: The biggest problem of polymer use is its lack of biodegradability. Since polymers cannot be degraded, they stay long underground, emitting toxic materials. • Disposal (2): Polymers like polyurethanes releases toxic hydrogen cyanide gas when they are burned. • Use of natural resources: Polymers are typically made of petroleum and other natural resources. C.9.1 • Describe the free-radical mechanism involved in the manufacture of low-density polyethene. Low density poly(ethene), LDPE The manufacture of low density poly(ethene) is carried out at very high pressures (1000 – 3000 atm) at a temperature of about 500 K. An initiator, such as an organic peroxide or a trace of oxygen, is added. Under these conditions free radicals are formed. Low density poly(ethene), LDPE • Termination takes place when two radicals combine. The average polymer molecule contains between about 4 x 103 and 4 x 104 carbon atoms with many short branches. The branches affect both the degree of crystallinity and the density of the material. LDPE generally has a density of about 0.92 g cm-3 and is used mostly for packaging. High density poly(ethene), HDPE High density poly(ethene) is manufactured by polymerizing ethene at a low temperature (about 350 K) and pressure (1 – 50 atm) using a Ziegler-Natta catalyst. The catalyst is a suspension of titanium(III) or titanium(IV) chloride together with an alkyl-aluminium compund (e.g. triethylaluminium Al(C2H5)3). The mechanism is complex and still not thoroughly understood. Essentially it involves the insertion of the monomer between the catalyst and the growing polymer chain. This is known as co-ordination polymerization (sometimes described as anionic polymerization). The titanium atom is attached to one end of the growing hydrocarbon chain and uses its empty d orbitals to form a co-ordination complex with the π electrons of the new incoming ethene molecule. High density poly(ethene), HDPE • The resulting polymer consists mainly of linear chains with very little branching. This gives ti a higher density (0.96 g cm-3) and a more rigid structure as the chains can fit together more closely. It is used to make containers and pipes.