Properties of Polyamide 66

advertisement

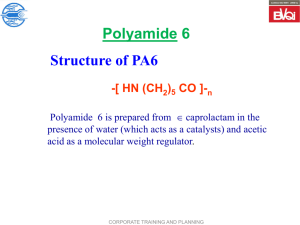

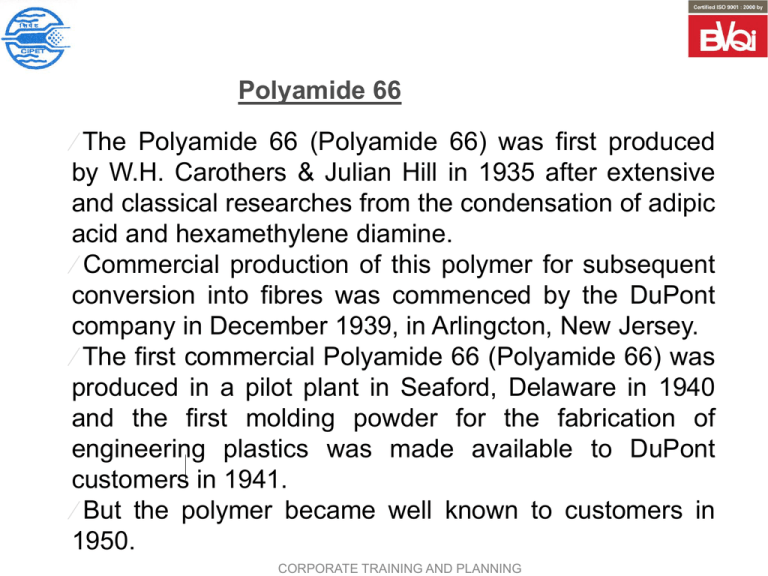

Polyamide 66 The Polyamide 66 (Polyamide 66) was first produced by W.H. Carothers & Julian Hill in 1935 after extensive and classical researches from the condensation of adipic acid and hexamethylene diamine. Commercial production of this polymer for subsequent conversion into fibres was commenced by the DuPont company in December 1939, in Arlingcton, New Jersey. The first commercial Polyamide 66 (Polyamide 66) was produced in a pilot plant in Seaford, Delaware in 1940 and the first molding powder for the fabrication of engineering plastics was made available to DuPont customers in 1941. But the polymer became well known to customers in 1950. CORPORATE TRAINING AND PLANNING Monomer Ingredients for Polyamide 66 Adipic Acid The adipic acid and hexamethylene diamine are used for preparation of salt (Hexamethyelene Diammonium adipate) CORPORATE TRAINING AND PLANNING Monomer Ingredients for Polyamide 66 Hexamethylene Diamine Hexamethylene diamine is conventionally prepared from adipic acid via adiponitrile CORPORATE TRAINING AND PLANNING Chemistry of Preparation of Polyamide 66 The Polyamide 66 is prepared from Polyamide salt, which is prepared by reacting the hexamethylene diamine and adipic acid in boiling methanol. A 60% aqueous solution of the salt is then run into a stainless steel autoclave together with a trace of acetic acid to limit the molecular weight CORPORATE TRAINING AND PLANNING Manufacturing of Polyamide 66 The polymerization of Polyamide 66 is carried out in several different reactors connected in series Flow Diagram of Continuos Process of Polyamide 66. CORPORATE TRAINING AND PLANNING Manufacturing of Polyamide 66 The starting material is an aqueous solution of polyamide salt (AH salt) containing equivalent quantities of hexamethylene diamine and adipic acid The solution with about 60% solid content is fed into the first horizontal cylindrical reactor then divided into several components where the water is drawn off as vapor and precondensate of low mol. wt. is formed. This is pumped into the second reactor, which is a heated tube reactor with a gradually increasing diameter. The Polycondensation proceeds here and vapor forms at falling pressure. The next step is the removal of water in a steam separator followed by feeding the polymer melt by means of a screw conveyor into the last reactor, which consists of a heated screw conveyor where water vapor is again withdrawn and the final poly-condensation equilibrium is attained. CORPORATE TRAINING AND PLANNING Characteristics of Polyamide 66 The general characteristics of Polyamide 6 is summarized below Hard and though thermoplastic Good abrasion resistance How co-efficient of friction High tensile strength Good dimensional stability Low tendency to work Smooth appearance of surface Average to high surface gloss Resistance to lubricants, engine fuels, grease etc. are respectively 140 - 170°C and 80 - 100°C. CORPORATE TRAINING AND PLANNING Characteristics of Polyamide 66 Good resistance to coolants, refrigerants, paints, solvent cements. Resistant to aqueous solution of many inorganic chemicals. Posses high HDT Attached by strong acids, phenols, cresol at devoted temperature Poor or resistance High temperature resistance Low co-efficient of linear thermal expansion High water absorption CORPORATE TRAINING AND PLANNING Properties of Polyamide 66 Properties Units Specific gravity Tensile strength Tensile modulus Flexural modulus Elongation at break Impact strength Hardness Deflection temperature under load (1.82 Mpa) Coefficient of linear expansion Water absorption, 24hrs Dielectric strength Dielectric constant Volume resistivity Power factor Melting point Glass transition Temperature Mould shrinkage ---MPa MPa Mpa % izod, Notched, J/m 0C mm/mm/0C % KV/mm 10-6 Hz Ohm.m 0C 0C % CORPORATE TRAINING AND PLANNING Values PA-6 1.14 90 3400 2896 20 37 M90 104 81 x 10-6 2.8 108 3.2 10-13 0.025 255 60 1.0-2.5 Properties of Polyamide 66 Mechanical Properties The mechanical properties of moulded polyamide material depend on molecular weight, crystallinity and moisture content. The stress/ strain performance of the material is low and high strain rate gives a completely different impression. The useful information for design of the product from polyamide 6 can be derived from creep modulus and isochronous stress / strain curves which characterise the behaviour of mouldings under constant mechanical stress over long periods. Polyamide 6 is widely used for bearings because of their good slip and dry running characteristics, high compressive strength and wear resistance and adequate shape retention at elevated temperatures. The polyamide articles are found in applications where dimensional stability is important CORPORATE TRAINING AND PLANNING Properties of Polyamide 66 Thermal Properties The thermal expansion is highly dependent on temperature The service temperature in air without mechanical loading for shortterm 140 - 160°C and for long – term is 80 - 100°C The UL index value is 75°C (The temperature at which property values decreases to less than 50 percent of initial values) The change of specific volume of glass reinforced plastics as a function of temperature and pressure (PVT diagram) is significant CORPORATE TRAINING AND PLANNING Properties of Polyamide 66 Electrical Properties The utility of a plastic in electrical engineering is determined by its volume resistance, surface resistance, dielectric strength and tracking resistance as function of temperature and especially in the case of polyamide with moisture content The electrical properties can also change on heat ageing In contrast to other thermoplastics PA 6 is distinguished by high tracking resistance and dielectric strength under normal condition with continuous absorption of moisture The surface resistance is such that no dust deposits are formed as a result or electrostatic charge The dielectric properties are highly dependent on temperature and moisture CORPORATE TRAINING AND PLANNING Properties of Polyamide 66 Water absorption Compared to other plastics, polyamide 6 absorb relatively large amount of water The resultant increase in volume affects the dimensions of the mouldings Conditioning ie., accelerated and defined absorption of water is thus an important final processing step which ensures that the molding has almost constant properties and dimensions in use Conditioning also increases toughness although hardness and stiffness fall Moldings are thus most effectively conditioned in hot water, a warm, humid atmosphere or in saturated steam CORPORATE TRAINING AND PLANNING Properties of Polyamide 66 Optical Properties Mouldings of crystalline polyamides are translucent to opaque depending on thickness, processing conditions and molding compound. Permeability to water vapour and gases The low permeability of polyamide to gases and vapours is important for their use as packaging materials and it is tabulated in the Table- 3. The permeability to watervapour decreases in the order PA 6, PA 66, PA 610, PA 612, PA 11 and PA 12 while permeability to gases increases slightly Permeability increases considerably with increasing moisture content and temperature It is also affected by the processing method, degree of orientation and crystallinity CORPORATE TRAINING AND PLANNING Properties of Polyamide 66 CORPORATE TRAINING AND PLANNING Properties of Polyamide 66 Chemical Properties It is inherently resistant to lubricants, engine fuels, hydraulic fluids, coolants, refrigerants, paints, solvent, cleaners and aliphatic and aromatic hydrocarbons. They are also resistant to aqueous solution of many inorganic chemicals. Polyamide 6 is gradually attacked over a time by hot water, acids, phenols and few chlorinated hydrocarbons. The Polyamide present no toxicological problems because they are insoluble in body fluids and are biologically inert. CORPORATE TRAINING AND PLANNING Properties of Polyamide 66 Weathering Properties The weatherability of polyamide 6 is poor unless a suitable stabilizer is incorporated PA 6 is resistance to boiling water and can be sterilized Deterioration can be expected only after months of exposure to hot water particularly if it contains high concentration of oxygen or oxidising substances Fault free, low stress, pigment or unpigmented articles generally have a service life in warm, dry atmosphere in excess of five years and of more than three years in warm humid atmosphere without affecting functional properties Moldings with high carbon black content (approx. 2%) donot become brittle even after ten years at outdoor weathering in warm dry or humid atmosphere CORPORATE TRAINING AND PLANNING Properties of Polyamide 66 Resistance to high energy radiation This plastics exhibit average resistance to high energy radiation The properties of unreinforced grades are affected to varying degrees by exposure to high energy radiation Some properties are affected by medium dosages, others are almost unaffected by high dosages An energy dosage or 2000 KJ/Kg (200 Mrad) causes, for example a drop in impact strength of only 15 % to 30% The electrical properties are almost unaffected in the range upto 10000 KJ/ Kg Glass reinforced PA grades are extremely resistant to radiation CORPORATE TRAINING AND PLANNING Properties of Polyamide 66 Flammability Properties Unmodified Polyamides are rated as (selfextinguishing class) UL-V2 according to UL. With modification it can be identified selfextinguishing class UL–V 0. Polyamide start to decompose slowly at temperatures greater than 300°C. Between 450 and 500°C, combustible gases are formed which continue to burn after ignition. Polyamide burns with yellowish orange blue edged flame They melt, drip and continue to burn after the ignition source is removed, giving a smell of burnt horn The decomposition product formed upto 400°C are less toxic than those formed from wood under the same conditions at higher temperature they are equally toxic. The heat of combustion of unreinforced grade is approx. 29000 to 32000 KJ/Kg CORPORATE TRAINING AND PLANNING Properties of Polyamide 66 Toxicity Polyamide is odourless Taste problem encountered with polycondensation of caprolactam is overcome in recent years Neverthless food stuffs and beverages in aqueous phase should not be subjected to elevated temperature in polyamide vessels Work place where it is processed should be well ventilated Moulding compounds should need legislative requirement and it can be confirmed from the supplier also. All polyamides are physiologically inert They are compatible with tissue and can be used for artificial limbs Colorants are subject to various restrictions especially for toys CORPORATE TRAINING AND PLANNING Properties of Polyamide 66 Sterilization γ-Radiation sterilization of 25 KJ / Kg (2.5 Mrad) does not affect the mechanical properties of Polyamide. Natural or pigmented parts turn slightly yellowish CORPORATE TRAINING AND PLANNING Processing considerations Polyamide 66 for The Polyamide 66 is also processed with much precautions as like Polyamide 6. The annealing temperature of Polyamide 66 part is 149 – 177°C. The Polyamide 66 is processed in the temperature range of 260- 320°C. The material has to be predried at 80°C for 2 - 4 hours Injection moulding, Extrusion techniques, Compression moulding, Foam moulding and Rotomoulding techniques are used for processing the materials. While moulding Polyamide 66, the precautions what are taken for Polyamides 6 the some should be taken for Polyamide 66. CORPORATE TRAINING AND PLANNING Applications of Polyamide 66 Areas of applications are very similar to Polyamide 6. Appliances Automotive Business equipment Consumer Products Electrical Hardware Machinery and packaging CORPORATE TRAINING AND PLANNING Applications of Polyamide 66 Hammer handles of glass reinforced Polyamide are superior to wood they replaced (Application related to hardware) Hammer Handles CORPORATE TRAINING AND PLANNING Applications of Polyamide 66 Textile shuttle of glass reinforced Polyamide 66 with stand frictional heat and millions of impacts (Application related to machinery) Textile Shuttle CORPORATE TRAINING AND PLANNING Applications of Polyamide 66 Gide shoes for the hand rail of moving stairway are made of Polyamide 66 with molybdemum disulfide added for lubricity (Machinery) Gide shoes CORPORATE TRAINING AND PLANNING Applications of Polyamide 66 Polyamide elevators gibs slide thousand of miles against steel rails with minimum lubrication (Example of good abrasion resistance, application of machinery) Elevators Gibs CORPORATE TRAINING AND PLANNING Applications of Polyamide 66 Trimming sprocket for automobile cam shaft has Polyamide 66 teeth for long wear and noise reduction (Automotive) Trimming Sprocket & Gears CORPORATE TRAINING AND PLANNING Applications of Polyamide 66 Countless electrical coils are wound on Polyamide 66 (Electrical) Electrical coils & Connectors CORPORATE TRAINING AND PLANNING Applications of Polyamide 66 Self -Extinguishing Polyamide 66 used for television tuner parts Television Tuner Parts CORPORATE TRAINING AND PLANNING Applications of Polyamide 66 Spatula blades and spoons of Polyamide 66 (consumer products, kitchen) Spoons CORPORATE TRAINING AND PLANNING Applications of Polyamide 66 Applications as gears, bearings in Pump parts Gears Bearings CORPORATE TRAINING AND PLANNING Applications of Polyamide 66 In Automotive Applications Manifolds Wheel covers CORPORATE TRAINING AND PLANNING