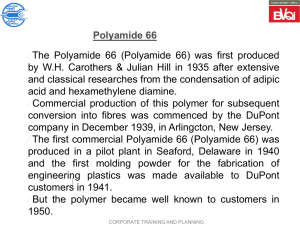

Polyamide 6

advertisement

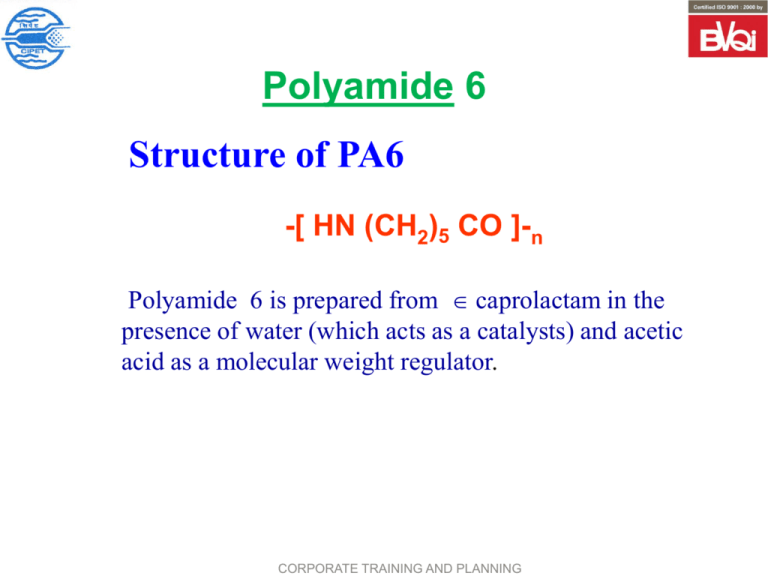

Polyamide 6 Structure of PA6 -[ HN (CH2)5 CO ]-n Polyamide 6 is prepared from caprolactam in the presence of water (which acts as a catalysts) and acetic acid as a molecular weight regulator. CORPORATE TRAINING AND PLANNING Polyamide 6,6 Structure of PA 6,6 -[ HN (CH2)6 NH-CO (CH2)4 CO]-n The Polyamide 66 is prepared from Polyamide salt, which is prepared by reacting the hexamethylene diamine and adipic acid in boiling methanol. CORPORATE TRAINING AND PLANNING POLYAMIDE 6 Monomer Structure caprolactam CORPORATE TRAINING AND PLANNING POLYAMIDE 6,6 Monomer Structure Nylon Salt CORPORATE TRAINING AND PLANNING Monomer Preparation: 1. caprolactam Cyclohexanone 2. Nylon Salt Adipic Acid & Hexamethylenediamine CORPORATE TRAINING AND PLANNING Preparation of Polyamide 6 Polyamide 6 is prepared from caprolactam in the presence of water (which acts as a catalysts) and acetic acid as a molecular weight regulator. The typical combination is charged into the vessel and reacted under a nitrogen blanket at 250°C for about 12 hours. CORPORATE TRAINING AND PLANNING Manufacturing of Polyamide 6 The schematic diagrams of the continuous polymerization of caprolactam to produce Polyamide 6 Flow diagram of continuous production of Polyamide 6 CORPORATE TRAINING AND PLANNING Manufacturing of Polyamide6 The VK tube is used in the polyamide process. A lactam melt with a relatively high water content (~15%) is fed to the top of the VK tube equipped with a stirrer and heating coil. The water vaporises at the top, when viscosity is still low, to give a residue of the desired composition. In the lower part of the tube, the equilibrium degree of polymerisation is reached with an increasing viscosity of the melt. The polymer is drawn off at the bottom and granulated. Its equilibrium content of caprolactam and oligomers is about 10% at a final temperature of 270°C. The monomer and oligomers are extracted from the chips with hot water, and the polymer is subsequently dried with hot gas in a ventricle cylinder hot dryer. CORPORATE TRAINING AND PLANNING Preparation of Polyamide 6,6 The Polyamide 66 is prepared from Polyamide salt, which is prepared by reacting the hexamethylene diamine and adipic acid in boiling methanol. CORPORATE TRAINING AND PLANNING Manufacturing of Polyamide 6,6 The polymerization of Polyamide 66 is carried out in several different reactors connected in series CORPORATE TRAINING AND PLANNING Manufacturing of Polyamide 6,6 The starting material is an aqueous solution of polyamide salt containing equivalent quantities of hexamethylene diamine and adipic acid The solution with about 60% solid content is fed into the first horizontal cylindrical reactor then divided into several components where the water is drawn off as vapor and precondensate of low mol. wt. is formed. This is pumped into the second reactor, which is a heated tube reactor with a gradually increasing diameter. The Polycondensation proceeds here and vapor forms at falling pressure. The next step is the removal of water in a steam separator followed by feeding the polymer melt by means of a screw conveyor into the last reactor, which consists of a heated screw conveyor where water vapor is again withdrawn and the final polycondensation equilibrium is attained. CORPORATE TRAINING AND PLANNING Relations of Structure and properties of Polyamide 6 The following structural variables affect the properties. The distance between the repeating –CONH- group The number of methylene groups in the intermediates The molecular weight N- substitution Co-polymerization CORPORATE TRAINING AND PLANNING Characteristics of Polyamide 6 & 6,6 (For identification) The material is semicrystalline and having high water absorption capacity. It is milky white - yellow colour It is identified by the smell of burnt horn when burned, yellow flame with a blue halo, can be formed into a filament. Its melting point is 215°C (PA6) & 264°C(PA66) Its short term and long term service temperature are respectively 140 - 160°C(For PA6,6 10°C more) and 80 - 100°C. CORPORATE TRAINING AND PLANNING Characteristics of Polyamide 6 & 6,6 The general characteristics of Polyamide 6 & 6,6 is summarized below Hard and tough thermoplastic Good abrasion resistance Low co-efficient of friction High tensile strength Good dimensional stability Low tendency to work Smooth appearance of surface Average to high surface gloss Resistance to lubricants, engine fuels, grease etc. CORPORATE TRAINING AND PLANNING Characteristics of Polyamide 6 & 6,6 Good resistance to coolants, refrigerants, paints, solvent cements. Resistant to aqueous solution of many inorganic chemicals. Posses high HDT Attached by strong acids, phenols, cresol at devoted temperature High temperature resistance Low co-efficient of linear thermal expansion High water absorption CORPORATE TRAINING AND PLANNING Comparison between different polyamides Polyamide 6 Polyamide 66 processing easy easy Strength good better Abrasion resistance Low High Toughness Low higher Water absorption high high cost less Little High CORPORATE TRAINING AND PLANNING Comparison Performance Properties CORPORATE TRAINING AND PLANNING Grades of Polyamide 6 The Polyamide 6 is available in various grades Injection molding grade Extrusion grade Rotational Molding grade Fluidized bed coating grade CORPORATE TRAINING AND PLANNING Processing considerations for Polyamide 6 The material has to be predried at 80°C for 2 - 4 hours While molding Polyamide attention on the following points is essential. High Injection speed of the molding machine Control of shot or size Minimizing drooling by nozzle of reverse tapper type. Shrinkage of the part Annealing at 130° to 149°C for 10 - 20 hrs. CORPORATE TRAINING AND PLANNING Processing considerations Polyamide 66 for The Polyamide 66 is also processed with much precautions as like Polyamide 6. The annealing temperature of Polyamide 66 part is 149 – 177°C. The Polyamide 66 is processed in the temperature range of 260- 320°C. The material has to be predried at 80°C for 2 - 4 hours Injection moulding, Extrusion techniques, Compression moulding, Foam moulding and Rotomoulding techniques are used for processing the materials. While moulding Polyamide 66, the precautions what are taken for Polyamides 6 the some should be taken for Polyamide 66. CORPORATE TRAINING AND PLANNING Applications of Polyamide 6(Areas of Applications) Appliances Automotive Business equipment Consumer products Electrical Hardware Machinery Packaging CORPORATE TRAINING AND PLANNING Applications of Polyamide 6 Appliances Laundry equipment Cooking equipment Dishwashers and disposers Cooling equipment Consumer electronics Housecleaning equipment Small kitchen appliances Sewing machine Personal care and grooming CORPORATE TRAINING AND PLANNING Applications of Polyamide 6 Automotive Chassis parts Power plant Decorative body parts Functional body parts Electrical parts Fuel system Instrumentation Heating, ventilating, air-conditioning Accessories CORPORATE TRAINING AND PLANNING Applications of Polyamide 6 Business equipment Business machines Vending machines Office equipment CORPORATE TRAINING AND PLANNING Applications of Polyamide 6 Consumer products Kitchen utensils Toys Sporting goods Apparel fitments Personal accessories Photographic equipment Football face guards are made of Nylon 6 because of its great toughness Musical instruments Brush bristles Packaging Film for cooking Fishing line Tennis racquet CORPORATE TRAINING AND PLANNING Applications of Polyamide 6 Electrical Industrial controls Wiring and associated devices Industrial connectors Batteries Telephone parts Switches CORPORATE TRAINING AND PLANNING Applications of Polyamide 6 Hardware Furniture fittings Door and window fittings Tools Lawn and garden implements Boat fittings CORPORATE TRAINING AND PLANNING Applications of Polyamide 6 Machinery Agricultural Mining and oil drilling Food processing Printing Textile processing Engine parts Pumps, valves, meters, filters Air blowers Material handling equipment Standard components Gears Cams Sprockets Bearings Gaskets Pulleys Brushes CORPORATE TRAINING AND PLANNING Caster Wheels Spur and Pinion gears Bushing and Bearing Applications of Polyamide 6 Packaging Film and coated substrates Polyamide 6 film for meat packaging CORPORATE TRAINING AND PLANNING Applications of Polyamide 66 Areas of applications are very similar to Polyamide 6. Appliances Automotive Business equipment Consumer Products Electrical Hardware Machinery and packaging CORPORATE TRAINING AND PLANNING Applications of Polyamide 66 Hammer handles of glass reinforced Polyamide are superior to wood they replaced (Application related to hardware) Hammer Handles CORPORATE TRAINING AND PLANNING List of Manufacturers/ Suppliers of Polyamide 6 CORPORATE TRAINING AND PLANNING