The Dry Grind Corn to Ethanol Process

National Corn-to-Ethanol Research Center

Southern Illinois University

Education and Workforce Development

400 University Park Drive

Edwardsville, Illinois 62025-3604

Office: (618) 659-6737 ext. 239

Fax: (618) 659-8762

TM

www.ethanolresearch.com

A copyright statement is as follows:

---------------------------Copyright © 2007, Board of Trustees of Southern Illinois University, National Corn to Ethanol Research Center,

Edwardsville, Illinois 62026

All rights reserved.

These materials are protected by copyright and may not be reproduced, copied, displayed, or disseminated

in any media without the express consent of the National Corn to Ethanol Research Center

----------------------------

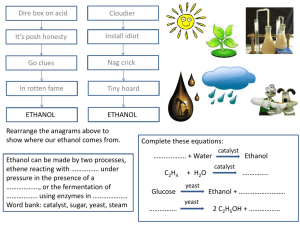

CO2

The Corn to Ethanol Process

TM

Enzyme

National Corn-to-Ethanol Research Center, SIUE

© 2007 All Rights Reserved

Ammonia

2

Start Here

1

3

Hammer Mill

5

4

Water

Enzyme

9

6

Urea

Steam

Liquefaction

Slurry

Tank

(Cooling)

Jet

Cooker

Enzyme

4

8

Fermentation

(Heating)

Yeast

7

(190 Proof )

5%

Gasoline

Added

Denatured

Ethanol

9

Molecular

Sieve

10

11

Distillation

System

9

(200 Proof )

(Recycled Water)

Dried Distillers

Grain with Solubles

13

Evaporator

Drum Dryer

(Syrup)

12

(Thin

Stillage)

Centrifuge

( Wet Cake)

(Whole

Stillage)

The Dry-Grind Corn

to Ethanol Process

The dry-grind ethanol fermentation process (from kernel to ethanol)

requires approximately 54 to 58 hours. The time consuming step is

the actual fermentation which requires almost 50 hours.

One bushel of corn (56 pounds) yields approximately 2.8 gallons of

ethanol, 18 pounds of carbon dioxide, and 18 pounds of Dried

Distillers Grain with Solubles (DDGS).

1

Hopper

Most corn grown for ethanol production is #2 yellow dent corn, so named

because of the indentation that occurs on top after the kernel is allowed

to dry.

Midwest Corn typically contains: 70-72% starch, 9% protein, 4% oils, and

9% fiber on a dry basis, plus approximately 15% water.

2

Hammer Mill

The corn kernels are milled to a coarse flour and passed through a fine

mesh screen.

The corn particle sizing is a compromise between:

(A) grinding fine enough to provide increased surface area to make

starch granules available for reaction with water and enzymes and

(B) leaving large enough particles for drying the Distiller’s Grain

at the end for animal feed.

Hammer Mill

Water

Ammonia

or

Sulfuric Acid

Slurry Mixer

3

(Corn flour)

Slurry

Tank

(Recycled Water)

Corn flour from the hammer mill is mixed first in the slurry mixer

with hot water and alpha-amylase enzyme.

The resulting slurry is adjusted to a pH of 5.6 to 6.0 with acid or base.

3

alphaamylase

Slurry

Tank

Temperature = 185 oF

pH = 5.6 to 6.0

% Solids = 32%

Only one third of the total alpha-amylase is added in the slurry

Tank.

The remaining alpha-amylase will be added later in the

liquefaction tank.

Steam

holding column

Slurry Mash

Jet Cooker

The slurry mash is heated to above 220°F in a jet cooker using direct

steam.

Upon exiting the jet cooker, the corn slurry enters a holding column

where the mixture is held for 5 to 10 minutes.

holding column

5

Liquefaction

Tank

Temperature = 185 oF

pH = 5.6 to 6.0

% Solids = 30%

alpha-amylase

From the holding column, the slurry enters a Liquefaction Tank (5).

Additional alpha-amylase is added and the mash is allowed to react

(liquefy) for approximately 30 minutes.

The jet cooking and liquefaction steps break apart the long starch

granules. The shorter molecules are called dextrin.

CO2

gluco-amylase

6

Liquefaction Tank

Yeast

7

9

8

Fermentation

Tanks

Temperature = 90 oF

pH = 3.5 to 4.0

SSF

A second enzyme, gluco-amylase (6), is added to complete the dextrin

breakdown to glucose.

Glucose is converted by yeast (7) through a series of multi-step reactions

to ethanol and carbon dioxide in the fermentation tanks (8).

Over the past 10 years, many ethanol plants have started adding the

saccharifying enzyme (gluco-amylase) directly to the fermentation tank.

This faster process is know as Simultaneous Saccharification and

Fermentation (SSF).

CO2

9

Fermentation

Tanks

Carbon dioxide is a major co-product in the fermentation process.

Every bushel of corn (approximately 56 pounds) will produce

approximately 18 pounds of carbon dioxide gas.

Yeast

7

Fermentation

Tanks

Yeast can withstand extreme environmental stresses including high

ethanol concentrations (final concentrations of 12-18% by volume), as

well as organic acids produced by contaminating bacteria. Fortunately,

most bacterial contaminants do not grow below pH 4.

Contaminating microorganisms can lower the yield by converting glucose

to some undesirable fermentation products like fusel oils (undesired

alcohols), acetic acid, and lactic acid. Antibiotics maybe added to the

fermentation process to minimize bacterial contamination.

Distillation System

Beer Well

(beer)

At the end of fermentation, the product is called beer and contains 12%

or higher concentration of ethanol. The beer is typically stored in a tank

referred to as the beer well.

The distillation system typically consists of three columns.

(gases)

Molecular Sieve

Distillation System

Beer Well

(whole stillage)

Centrifuge

First, the beer is passed through a degassing column (gray) to remove

carbon dioxide and other gases.

Separation of ethanol/water from the non-converted solids mixture occurs

on the beer column (blue). These non-converted solids (whole stillage)

fall to the bottom and are sent to the centrifuge for separation.

Further separation of the ethanol/water mixture is accomplished using a

rectifier column (red). The 190 proof ethanol is sent through a

molecular sieve column to convert it to 200 proof.

190 Proof

Denatured

Ethanol Tank

Molecular

Sieve

10

from Rectifier Column

Temperature > 280 oF

Pressure = 6 psig

200 Proof

Conventional distillation methods yield 190 proof (95% pure ethanol)

because ethanol and water form an azeotrope. An azeotrope is simply a

mixture of two substances that form a constant boiling point mixture.

The remaining 5% water is removed by molecular sieves, which rely on

pore sizes to separate the smaller water molecules from ethanol.

11

Denatured Ethanol

5%

Gasoline

Added

Molecular Sieve

Finally, anhydrous (100% or 200 proof) ethanol is denatured, typically

with 5% gasoline to exempt the ethanol from beverage alcohol taxes.

thin stillage

Centrifuge

whole stillage

wet cake

The solids materials remaining after distillation of ethanol from the beer

column is called whole stillage. Whole stillage contains 13-17% solids

and is composed primarily of small particles of corn that did not get

converted to ethanol. This whole stillage is separated in the centrifuge

into wet cake and thin stillage.

Wet cake is a more concentrated form of the whole stillage and

contains approximately 35% solids after leaving the centrifuge. Since it

contains mostly solids, it must be augured or conveyed to the drum

dryer.

backset

Evaporator

12

(thin

stillage)

Centrifuge

(wet cake)

Drum Dryer (syrup)

The thin stillage is primarily water with between 4 and 5% solids. The thin

stillage is evaporated down to a concentrated syrup in the evaporator.

The condensed water is recycled to the Slurry tank. This condensed

water is called backset and helps to conserve total water usage.

The remaining liquid is concentrated (called syrup) by evaporation and

mixed with the wet cake before entering the dryer. Syrup is

approximately 28-30% solids and contains mostly protein and oils from

the corn. The addition of syrup increases the nutritional value of the

DDG.

Evaporator

(syrup)

DDGS

Rotary Drum Dryer

Centrifuge

(wet cake)

Inlet Air Temperature = 600-1200 oF

DDGS Residence time = approximately 30 minutes

The mixture of syrup and wet cake is dried to generate Dried Distillers

Dried Grain with Syrup or Solubles (DDGS). DDGS is typically dried to a

10% moisture level.

The moisture content and correspondingly short shelf-life of wet distillers

grains limit use of this feed product to the immediate vicinity of ethanol

plants.

The shelf life of the DDGS can be lengthened by adding organic acids as

preservatives and removing almost all the moisture content.

NCERC

Distillers Dried

Grain with Solubles

13

In the dry grind process, corn is ground whole and fermented to ethanol.

The only major by-products are ethanol, carbon dioxide, and Distillers

Dried Grain with Solubles.

DDGS is sold primarily as cattle feed.

Grain

Qual

DE

pH

Particle Size

pH

HPLC

Hammer Mill

Liquefaction

Slurry

Tank

DE

TS %

pH

Proximate

Analysis

(Cooling)

Jet

Cooker

Fermentation

(Heating)

(190 Proof )

H2O %

9

Ethanol

Storage

Amino Acids

Total P

Proximates

Ash

etc.

DDGS

Drum Dryer

Distillation

System

Molecular

Sieve

9

(200 Proof )

(Recycled Water)

HPLC

Centrifuge

TS%

Evaporator

(Syrup)

Whole

Stillage

Centrifuge

(Thin

Stillage)

( Wet Cake)

TM