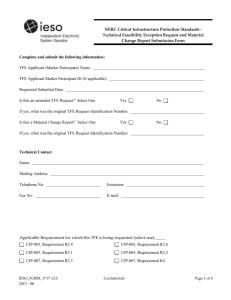

of pp-HMDSO Buffer Film

advertisement

Leading Technology for AMOLED Backplane and Encapsulation Eric Sun Technical Marketing Director CTO Office AKT Display Group Applied Materials, Inc. Display Innovation China 2014/Beijing Date: Oct. 15, 2014 External Use Display Technology Trend and Challenges Display Growing Visual Demand The eyes have it! GROWING DEMAND IMMERSION CONSUMPTION NEW TECHNOLOGIES EMOTION 3 INTERACTION External Use Display Technology Transitions TRANSISTOR DISPLAY TODAY SIZE RES. TV 55” 65” >70” Phone 5” 5.x” <7” TV FHD LCD a-Si OR OLED 4K 8K Phone >400ppi >600ppi >700ppi LTPS OR Form Factor 4 MOx External Use FLEX OLED AKT solutions_PVD Meter² of Chinese Capacity AKT PiVot® : Rotary PVD System for Array Backplane “. . . rotary targets are leveraging higher productivity and film quality to win a significant portion of new fab business.” - DisplaySearch, July 2014 6 External Use Rotary Cathode Array Enabling improved uniformity and defect control Uniformity Planar Rotary Open (Spacious) Architecture Cu Mo Al ITO IGZO Programmable Magnet Wobble Obstructed Uniform Gas Flow Defect Control Planar Rotary Rotating Target Full-surface erosion “Self-Cleaning” Minimum Nodules and ReDeposition with Rotary 7 Clean Target Erosion over Life External Use Enhancing PVD Processes for LTPS Optimize thickness & Rs unif. for better design rules; Reduce defects for Yield Leverage rotary target & directional magnet control to increase step coverage Ion bombardment & process tuning to minimize intrinsic film stress 8 Utilizing rotary target technology to decouple directional grain growth External Use ITO Optimization with H2 + O2 Process Adjust H2 to control amorphous crystal ratio, etch rate & residues Adjust O2 to control Rs & Rs uniformity Providing next generation capability for Advanced LTPS 9 External Use Optimizing IGZO Uniformity Two routes towards more uniform reflectivity profiles Ion Bombardment Control • Energetic oxygen ion bombardment locally increasing microwave reflectivity • Magnet movement improving as depo non-uniformities • PiVot can eliminate target imprints IGZO Post Annealing • As depo non uniformities in µPCR can be reduced by annealing µPCR 4.8% after annealing 4.7% THK uniformity 10 External Use Addressing Uniform MOx Electronic Properties IGZO TFT Structures IGZO Layer (µPCD) Unif. ≈ 40% No Magnet Wobble 4 TFTs for each position Unif. < 5% Optimized Wobble No Vth difference between or in front of targets Rotary Target Technology Mitigates Mura Effects for IGZO Backplanes 11 External Use AKT solutions_PECVD & TFE for OLED Gen6 PECVD Solution for High Resolution Display Substrate size System architecture 1500x1850 mm2 Single Substrate Operation System at Cluster Tool High Temperature Process Chamber (Max.5) : Max. 5 PC (High Temperature Process Chamber) : Annealing Chamber (Option) : DSSL (Dual Single Slot Load Lock) : Transfer Chamber : High Temperature Dual Arm Vacuum Robot Annealing Chamber (Option) Transfer Chamber w/Dual Arm Vacuum Robot Key Advantages • Uniformity • Particle Control • High System Reliability DSSL (Dual Single Slot Loadlock) External Use CVD Advantages : Uniformity and Low Defect Diffuser with HCG (Hollow Cathode Gradient) Top-Down RPSC (Remote Plasma Source Clean) Plasma Uniformity Control Uniform and Efficient Chamber Clean 14 External Use IEEE Innovation Award Patent Protected Demonstrated Uniformity up to Gen10 SiH4-SiO Uniform gas distribution Pressure Simulation w/Gas Deflector 2500 2500 2000 Uniformity ~11% DR (A/min) DR (A/min) 2000 1500 1000 Conventional design 500 Uniformity ~4% 1500 1000 500 0 0 0 500 1000 1500 0 Distance (mm) 500 1000 1500 Distance (mm) Enhanced diffuser assembly design for uniform gas distribution improves center dip profile on SiH4 based SiO process 15 External Use CVD Film Requirements for Reliable MO-TFT Back channel protection, H-less Interface Passivation to protect from attacking by OH and H2O S D Back channel protection during process D S a-IGZO a-IGZO G G Substrate Substrate ESL Structure BCE Structure Low defect, H- less Gate Insulator Low defect H-less Gate Insulator H-less Interface Low defect and H-less dielectric material is the requirement of gate insulator, etch stop and passivation for IGZO TFT for high reliability 16 External Use “One Cluster Solution” _ TFE Complete All TFE process in one cluster ► Vacuum Connection to EV tool ► Flexible Sequence control by MCC software ► High reliability Mainframe and Vacuum robot ► Mask deposition with Auto Mask Exchange and Mask Stocker Mask Stocker Concept CVD Chamber 2nd Layer pp-HMDSO (SiCN) Upper-stream Load Lock Example 3 5 Layer Lower-stream Load Lock OLED EV Tool IN OUT 1st Layer SiN Multiple Layer Stack 3rd Layer CVD Chamber SiN TFE Technology for OLED mass production 17 External Use AKT OLED Solutions: Thin Film Encapsulation Barrier: SiN Buffer: SiCN pp-HMDSO 18 • Multilayer structures with SiN layer and SiCN/pp-HMDSO buffer layer • SiN/SiCN structure: For TV or Rigid Display Applications • SiN/pp-HMDSO structure: For Flexible Mobile Applications • Both TFE structures have passed customer device lifetime evaluation External Use TFE : PECVD SiN Barrier Films SiN WVTR : 1x10-3 g/m2·day range at 1µm single layer SiN @ 85°C/85%RH (by MOCON and Ca-test method) WVTR at 85°C/85%RH is about 2 orders higher than the ambient conditions SiN properties (80°C process) Film RI DR A/min Unif. % %T @400nm Stress MPa TFE SiN 1.85 > 2500 < 10% > 90% < 100 • High optical transmittance (>90% at 400nm and above) • Excellent Barrier performance • High Depo. Rate 19 External Use TFE : PECVD pp-HMDSO Buffer Films >95% Transmittance 3 Layer (SiN/HMDSO) ~0 Stress Plasma polymerized HMDSO (pp-HMDSO) N2O Hexamethylsiloxane (HMDSO) 20 Film RI DR A/min Unif. % %T @400nm Stress MPa pp-HMDSO 1.45 > 5000 < 10% > 95% ~0 External Use TFE : “Flowability” of pp-HMDSO Buffer Film The buffer film we developed has a wide range of physical properties, from flowable liquid-like to rigid glass-like, depending on the process conditions A flowable buffer film can cover a particle without leaving any voids or diffusion channel around it. 8µm x 4µm Without high Stress Hot Point (Better Particle Coverage) No Sharp Corners Observed on the particle • High optical transmittance (>95% at 400nm and above) • High Depo Rate • Excellent Particle coverage 21 21 External Use TFE Layer Development Achievement Step Coverage Profile • Non-conformal profile – planarization of surface irregularity • No high stress hot spots – minimize film cracking during bending Particle Coverage • No voids around the particles – eliminate moisture permeation path • No high stress hot spots and good surface planarization Stack Film Integration • Stress matching by adding interfacial layer • Transmittance improved to ~85%T @ 400nm 22 External Use Summary • AKT PECVD, PVD & TFE technology and system performance have been recognized by display customers and are ready for next generation LTPS TFT, MOx TFT and AMOLED application. • AKT PiVot PVD system with advanced rotary target design enable high uniformity and low defect for metal & oxide film. • AKT continues to innovate PECVD tool by developing differentiated, valuable and sustainable solutions to support our customers’ needs; focusing on film thickness uniformity, and ultra-low particle performance. • AKT new developed TFE system with proven cluster architecture offers superior barrier/buffer layers and excellent performance for flexible AMOLED. AKT Solutions ready for next generation display with LTPS TFT, MOx TFT and AMOLED 23 External Use