Review on Carbotanium

advertisement

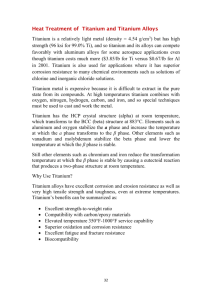

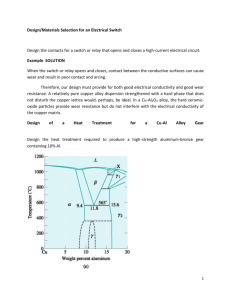

Review on Carbotanium Aditya Chandurkar Outline • • • • • • Objective Titanium processing Carbon fibre Titanium Carbon fibre bonding Applications Future Work Objective • Smart material • How it can be made • Where can it be applied Titanium • Titanium is named after the Titans, the powerful sons of the earth in Greek mythology. • Titanium is the forth abundant metal on earth crust (~ 0.86%) after aluminum, iron and magnesium. • Have similar strength as steel but with a weight nearly half of steel. • Not found in its free, pure metal form in nature but as oxides, i.e., ilmenite (FeTiO3) and rutile (TiO2) Production of Titanium alloys • Extraction process – Kroll process • Melting Process ESR VAR EBM PAM Induction Skull Melting • Casting process – Investment Casting, laser fabrication • Forming Process – rolling, extrusion, forging • Heat treatment Physical Properties of TI Crystal Structure HCP (below 882.5 C) BCC (above 882.5 C) Atomic diameter 0.320 Density 4.54 g. cm-3 Melting Point 1667 • • • • • Experiences allotropic transformation (α-> β) at 882.5 C Highly react with oxygen, nitrogen, carbon and hydrogen Difficult to extract -> expensive High strength and toughness Used mainly in wrought forms for advanced applications where cost is not critical Classification of TI alloys • Commercially pure (CP) titanium alpha and near alpha titanium alloys • Alpha-beta titanium alloys • Beta titanium alloys Different crystal structures and properties allow manipulation of heat treatments to produce different types of alloy microstructures to suit the required mechanical properties. Beta Ti alloys • Beta stabilizers are sufficiently added to retain a fully β structure (avoid martensite formation) when quenched from the β phase field Metastable β alloys : Mo Eq. <25 Stable β alloys : Mo Eq. 25-40 Beta titanium alloys • β titanium alloys possess a BCC crystal structure, which is readily coldworked (than HCP α structure) in the β phase field • Microstructure after quenching contains equiaxed β phase • After solution heat treating + quenching giving very high strength (up to 1300-1400 MPa) • Metastable β Ti alloys are hardenable while stable β Ti alloys are non-hardenable Composition and applications of β titanium alloys Beta alloys Advantages • • • • • • • • • • • High strength to density ratio Low modulus High strength/high toughness High fatigue strength Good deep hardenability Low forging temperature Strip producible Cold formable Easy to heat Excellent corrosion resistance Excellent combustion resistance Disadvantages • • • • • • • • High density Low modulus Poor low high temperature properties Small processing window High formulation cost High springback Microstructural instabilities Interstitial pick up Carbon fibre • Collection of thin stand of material mostly composed of carbon atoms. • The carbon atoms are bonded together in microscopic crystals that are more or less aligned parallel to the long axis of the fiber. • The crystal alignment makes the fiber incredibly strong for its size. Several thousand carbon fibers are twisted together to form a yarn, which may be used by itself or woven into a fabric • The fabric is combined with epoxy is molded into shape to form various composite material Classification of Carbon Fiber • Carbon fibers are classified by the tensile modulus of the fiber. • Tensile modulus is a measure of how much pulling force a certain diameter fiber can exert without breaking • Ultra-high-modulus (modulus >450Gpa) • High modulus (modulus between 350-450Gpa) • Intermediate Modulus (modulus between 200-350Gpa) • Low Modulus and high tensile (modulus < 100Gpa, tensile strength > 3.0Gpa) • Super high tensile (tensile strength > 4.5Gpa) Raw Materials • 90% of the carbon fibers produced are made from polyacrylonitrile • remaining 10% are made from rayon or petroleum pitch • All of these materials are organic polymers, characterized by long strings of molecules bound together by carbon atoms The Manufacturing Process • • • • • • Part Chemical and Part Mechanical Spinning Stabilizing Carbonizing Treating the surface Sizing Carbon-Fiber • Advantages • Very low weight • High impact tolerance • Insensitive to temperature • Reduced maintenance costs • Long service life Disadvantages • • • • Oxidize readily between 600-700 C Very Expensive Complicated to produce High electrical conductivity of graphite particles Ti-Carbon Fibre Bonding • Using Adhesive • Ion bean enhanced deposition Applications • • • • Defense applications such as tank shields, Fighter plans. Aerospace applications Aircraft Applications Automotive applications Future work • Captain America’s Shield • Wolverines Claw • Body Armour Questions