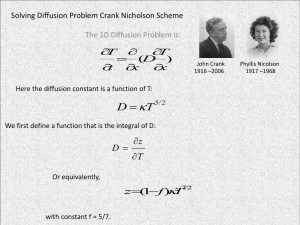

Diffusion (Review)

advertisement

Chapter 5: Mass-Transfer Controlled Solidification What You Will Learn: Solidification and Grain Growth Solidification Growth Mechanisms Numerical Simulation of Dendrite Spacing in Slab Casting More Complex Numerical Models for Dendritic Solidification 1 5.1- Solidification and Grain Growth T(°C) 400 Solidification of a phase (1st order) Grain morphology & spacing dependent on cooling rate L: Cowt%Sn L a L 300 200 TE 100 a L+a a: Cowt%Sn (Pb-Sn System) a+b [Adapted from Fig. 9.9, Callister 6e] 0 10 20 30 Co Co, wt% 2 (room T solubility limit) Sn 2 A Deeper Look at Grain Structure Secondary arms Macro-Scale: Engine Block ~1m Performance criteria: •Power generated •Efficiency •Durability •Cost Mesostructure: grains 1-10 mm Properties affected: •High cycle fatigue •Ductility Microstructure: dendrites & phases: 50-500 um Properties affected: •Yield strength •Tensile strength •High/low cycle fatigue •Thermal growth •Ductility Nano-structure: Precipitates 3-100 nm Properties affected: •Yield strength •Tensile strength •Low cycle fatigue Microstructure •Ductility Mass [D.R. Askeland and P. P. Phule, “The Science and andTransport in Formation Engineering of Materials”,Thomson, Brooks/Cole (USA) (2003)] Atomic Structure: 1-100 A Properties affected: 3 •Young’s Modulus •Thermal Growth Microstructures and Tensile Strength of Metals Alloys Secondary arm spacing λ 2 k 1 t m Relationships typically empirical λ2 [J.W. Callister: “Introduction to Materials Science and Engineering” 6th Ed, Jon Wiley and Sons (2004)] 4 Mass Vs. Heat Transfer In alloys Microstructure formation in alloys involves two main mechanism:the release (in the case of exothermic reactions) and subsequent diffusion of heat and the rejection and diffusion of solute The two diffusion processes described by similar mathematical processes, however diffusion of solute occurs on much smaller length scales and shorter time scales that the diffusion of heat mass diffusion is the rate limiting step 5 Length and Time Scales Heat & mass diffusion in parent phase Particle: heat & mass diffusion Diffusion length of heat Local interface velocity 2 ~αT/V Heat diffusion time ~αT/V Diffusion length of solute 2 ~ D /VMass diffusion time ~ D /V d i f f u s i o n l e n g t h o f h e a tα T 4 e a t d i f f u s i o n t i m e s c a l e α = ~ 1 0 h T 4 = ~ 1 0 d i f f u s i o n l e n g t h o f m a s sD m a s s d i f f u s i o n t i m e s c a l e D Mass transfer controls the small-scale structures Mass transfer is the rate limiting step 6 5.2- Solidification Growth Mechanisms 7 Solidification into a Thermal Gradient: Columnar Dendrites unstable solid/liquid interface Liquid between glass slides V motor cold plate(T c ) solid liquid L hot plate (T h ) thermal gradient: G (T h Tc ) / L •Aim: to understand microstructure This process is known as directional solidification evolution as a function of process parameters V and G 8 Anatomy of Solute Segregation During Solidification C(z 0 ) + T Cs z ko TM Ti Liquid diffusion profile Cs Co C(z=0 ) C s - CL C C C L C s (1 k o )C L C L (z ) C o ζ(t)= interface position Solute concentration In solid state Mass Transport in Microstructure Formation 9 Mass Transfer Kinetics of Solidification in 1D C (z 0 ) + Solid eventually will reach Co Cs ko Liquid diffusion C (z= 0 ) C o - C L (z ) C o ζ(t) Diffusion in solid and Liquid C L t CL 2 DL z Boundary conditions at moving interface (C L C S )A d (J L J S )A dt 2 V (t) d dt JL C DL C L (1-k o )C L z z n (y) Apply to liquid & neglect diffusion in solid phase Interface velocity 10 Planar Concentration Profile Steady 1D diffusion profile: C L t 0 Steady state 1D concentration profile solution of: V C L z 2 DL DL + boundary conditions d CL dz 2 dC L dz 0 V(1 k o )C L (z 0) z0 C L (z 0) Co ko C L (z ) C o Vz (1 k ) D o Steady state solution: C ssL (z) C o 1 e L ko , z 0 lD 2D L solute diffusion length V 11 “Perturbation” of Solidification Front y solid T z liquid T To Gz TM Ti Portion Phase diagram z Cs Co z ( y, t) V (y) C C C L C s (1 k o )C L ς(y,t) t Temperature dissipation >>solute diffusion Solute diffusion in metals negligible CL Mass transport dominates Ds 0 12 Perturbing the Steady-State Planar Solidification Front Consider the initial interface profile in the form of a since wave: ς(y, t) εsin(qy)e =growth amplitude q =instability frequency (q ) =growth rate ω(q)t 2 Assume perturbation of interface creates corresponding perturbation to concentration profile: C L (y, z, t) C L (z) εC L (y, z)e ss = p ω(q)t + 2D-Disturbance superimposed on the 1D steady-state profile 13 Effects of Interface Perturbation of Kinetics p Substitute trial function C L (y, z, t) C ss (z) εC L (y, z)e L Equation of solute diffusion C L t V C L z ω(q)t into solidification model Boundary conditions D L C L ( z ) nˆ V nˆ (1 k o ) C L ( z ) D L C L 2 + CL (z ) Co ko TM M LLp G M L CL (z ) Co Find conditions on ω versus q such that trial function is a valid solution Mass Transport in Microstructure Formation 14 Growth Rate of Perturbation Depends on its Wavelength w (q)= -2k o + 2k o -1+ 1+ (ql D ) 2 lD 2 1-d l q o D 2l T Fundamental length scales l T lD d o (q ) Perturbation grows q ς(y, t) εsin(qy)e Perturbation decays back to planar interface 15 ω(q)t Fundamental Length Scales of Solidification lT lD M L ΔC (Thermal length) G 2D (Diffusion length) V γ TM do L M ΔC L p (Capillary length) 16 Growth Rate of Perturbation Depends on its Wavelength (q ) Unstable range of wavelengths All wavelengths stable q q Range ofV, G (q ) such that 0 Range of V, G such that 0 Unstable growing perturbations V Planar solidification interface results Dendrites and cells Stable, planar interfaces G 17 Significance of Fastest Growing Unstable Wavelength Consider being within unstable range of V & G Within unstable range of V & G, fastest wavelength ( q c ) grows out first! Wavelength sets initial scale of solidification front (q ) qc q Mass Transport in Microstructure Formation c 2 qc 18 Relating the Initial Unstable Wavelength to Materials and Processing Parameters •To determine q c set d ω(q) 0 dq 1 2π γT M λc (1 k o ) V qc M C o L 2D L ko •Solving Eq. on page 14 gives 2 2D L γT M V M ΔC L 1 o 2 1 c l D d o 2 This approximation valid valid when G V DL Instability wavelength is mean of two length scales V DL M LC o (1 k o ) ko M L ΔC M L G c Which is called the “constitutional supercooling limit” Mass Transport in Microstructure Formation 19 Relating Dendrite Final Wavelength to Tip Radius f b Assume dendrite is an ellipsoid, described by Radius of curvature R r z R a b 1 ( r 0, z a ) where r 2 b 2 z 2 a 2 z ( r ) 1 ( z ) 2 3 2 2 b Ra a T TL TE G a 3D cross section view Eutectic temperature m 2b Relates wavelength to radius of curvature f TR Mass Transport in Microstructure Formation G 20 1 Relating Dendrite Tip Radius to Initial Wavelength Experiments have shown that tip radius roughly the same m b as the initial interface wavelength R c R r z a Recalling the form of the initial instability wavelength satisfies from 1.4 gives T TL - TE G a 1 1 R λ c l D d o 2 Mass Transport in Microstructure Formation 2D L γ 2 V ΔT 21 Relating Final Dendrite Spacing to V and G •Cell spacing depends on V and G c b r R Material parameters z ML slope of liquidus of binary alloy [K/%wt] surface tension energy of solid/liquid interface DL diffusion constant of liquid L latent heat of fusion T T T L E Material + process parameters 1 Eutectic temperature do " capillary length" lD " diffusion length" 1 3T 2 2 D L TM 4 c G V L T 22 5.3- Numerical Simulation of Dendrite Spacing in Slab Casting T liquid T mold z Liquid mold th e rm a l g ra d ie n t G (t) Nucleation of solid seed crystals near mold wall Tliquid T melt Tmold Tmelt m Mold wall z at Dendrites early time Thermal length scale Columnar front later times a thermal diffusion constant Mass Transport in Microstructure Formation 23 Crude Model of Thermal Gradient and Solidification Rate T liquid T mold z Liquid mold th e rm a l g ra d ie n t G (t) Tliquid T melt G T liquid T mold at Tmold Tmelt z V (t ) at Use these in c formula a t Average solidification front speed Thermal length scale a thermal diffusion constant Mass Transport in Microstructure Formation 24 Crude Estimate of Columnar Spacing 1 1 3 T 2 2 D LTM Substituting time dependent values V(t) and G(t) into: c G V T 1 4 1 2 3 T 2 D LTM c T a T at t 4 Inter-dendrite spacing widens as solidification front moves toward the centre of cast Mass Transport in Microstructure Formation 3 c const t 8 c (t ) 25 Numerical Algorithm of Heat Transfer & Solidification integers ::i,j Define variables Initialize T update 0,0 node real*8 :: arrays :: T(0:N,0:N), GRAD(1:N-1,1:N-1) update N,0 node arrays ::DER(1,N-1) update N,N node t update 0,N node C(i,j)=f(i,j) Find position of liquidus temperature Calculate gradient and V for time=1,Nmax t increment time by for i=1,N-1 Compute Dendrite spacing Print Temperature array at specified times END time loop for j=1,N-1 Apply Interior Node explicit update of Diffusion Equation Time loop end end for j=1,N-1 Left/Right Surface boundary update (i=0 & N) end for for i=1,N-1 Top/bot Surface boundary update (j=0,N) end run 26 Updating the Interior Nodes T n 1 T n i 1, j 2T n i, j T n i 1, j 2 x n i, j T i, j ta T n i 1, j 2T n i, j T n i 1, j 2 y Point-wise “explicit” time marching based on temperatures at previous time step. (Like the mass transfer code in Ch 4) A pply to (i=1,...,N -1, j=1,...,N -1) nodes 27 Loosing Heat Via the Boundary Conditions Heat Transfer Coefficient Left/Right wall Example: T k . Apply: T0 T1 wall . i=0 T m ould x h T m elt T m ould . i=1 . . I=N-1 . i=N T m ould T w all xh T1 Tmould k T N T N 1 T w all xh T N 1 Tmould k 28 Remainder of code to be developed in a project Require: Start will 2D mass transfer (i.e. diffusion code from Chapter 4) and Change C(i,j)T(i,j) “Gut” the previous initial and boundary conditions and replace with the ones defined on the previous page Heat Transfer Coefficient Predict: Columnar Spacing using Formula on page 22 5.4- More Complex Models of Dendrites Solidification Adaptive finite element mesh Initial conditions solid liquid G: thermal gradient V: pulling speed PVA-1.5mol% ACE GV=5K/s liquid-side concentration solid state concentration 30 See http://mse.mcmaster.ca/faculty/provatas for movie download Predicted Spacing Between Dendritic Arms Inter-dendritic tip spacing set by interplay between fundamental length scales: diffusion length, thermal length and surface tension Dimensionless Length Scales: Dimensionless wavelength Dimensionless velocity Onset wavelength lD lD clT 1 1 vlT * lD lD (, d l, l) c lT d o 2 D v m c G T L m c oD T clT Scaling hypothesis: lD lT fc lD 31 Computer Generated Dendrite Spacing Chart Scaling based on physical length scales LT therm al length lD LD diffusionlength C lT c (lT,lD,do) Experiments PF Simulations Scaling function independent of material parameters Application to Industrial alloys 1 1 lT * lD lD Scaled wavelength Scaled velocity See also: [M. Greenwood, M. Haataja and N. Provatas, PRL (2004)] 32 Fortran Program to Simulate Dendritic Solidification Go to the Chapter 5 directory retrieve code: “ModelC_alloy” This code is too complex to examine in this class Will use this as a computational “tool” to study solidification properties You will use this code in a project to determine: Dendrite growth rate Vs. undercooling Centre-line concentration in dendrite Vs. undercooling 33 Definition of Undercooling & Supersaturation T Steady-state tip growth rate Vs. Time ? Alter Supersaturation: (T ) CL Co Solid-state concentration? CL Cs TM (T1 ) 0 T1 Undercooling: T (T 3 ) 1 T3 Cs Co CL C Mass Transport in Microstructure Formation 34