even longer project overview - Department of Mechanical Engineering

advertisement

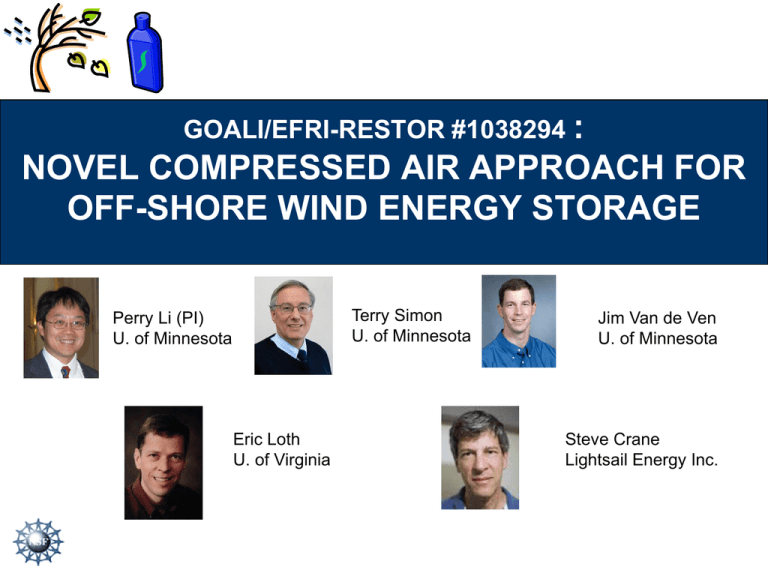

GOALI/EFRI-RESTOR #1038294 :

NOVEL COMPRESSED AIR APPROACH FOR

OFF-SHORE WIND ENERGY STORAGE

Terry Simon

U. of Minnesota

Perry Li (PI)

U. of Minnesota

Eric Loth

U. of Virginia

Jim Van de Ven

U. of Minnesota

Steve Crane

Lightsail Energy Inc.

Near Isothermal Compressed Air Energy Storage Approach For

Off-Shore Wind Energy using an Open Accumulator

Perry Y. Li (PI), Terry Simon, Jim Van de Ven, Eric Loth* and Steve Crane**

University of Minnesota, *University of Virginia, and **LightSail Energy

Challenges:

•Wind energy is intermittent, difficult to predict

•Mismatch between supply and demand

•Potential disruption of base power supply

•Wind turbines are under-utilized: typical

capacity factor < 50%

•High cost of installation, transmission and

interconnect for off-shore wind

Goal: Develop a scalable and rampable system

for storing wind energy locally prior to

electricity generation

Benefits:

•

•

•

•

Predictable output

Store energy when low demand/high supply &

regenerate energy during high demand/low supply

Downside electrical generator, transmission, and

interconnect

Increase capacity factor

Acknowledgement:

NSF-EFRI #1038294

UMN: IREE RS-0027-11;

NSF-CCEFP–2C.1

http://www.me.umn.edu/~lixxx099/EFRI_CAES

http://www.me.umn.edu/~lixxx099/EFRI_CAES

Challenges of wind power:

• Wind energy is intermittent, difficult to predict: disruptive to electrical grid

• Mismatch between supply and demand

• Wind turbines are under-utilized: typical capacity factor < 50%

Power

Rated capacity

Wind power

Unused capacity

Demand

Generated

Generatedpower

power

w/ow/storage

storage

Time

Goal: Develop a scalable and rampable system

for storing wind energy locally prior to

electricity generation

Benefits of local energy storage:

•

•

•

Predictable, reliable output

Increased energy capture

Downsize components, increase capacity factor

Approach

• Store energy in hi-pressure (300bar) compressed air vessel

• High energy density relative to pumped-hydro

• Not site specific, scalable and cost-effective

• Isothermal compression/expansion

• Efficient operation

• Hybrid hydraulic-pneumatic operation

• Rapidly rample, capable of capturing large transient power

4

Li et al. Near Isothermal Compressed Air Energy Storage Approach For Off-Shore Wind Energy using an Open Accumulator

Stores energy locally before conversion to electricity

•Downsize generator and transmission line

Open accumulator:

• Constant pressure

• Liquid port -> high power/low energy path

• Air port -> low power/high energy path

=> Downsize air compressor/expander

Multi-Disciplinary Research

• Heat transfer

• Fluid Flow

• Nano-textured surfaces

• Machine Design

• Fluid power

• Systems dynamics & control

Liquid Piston Near-isothermal air

compressor/expander

Active spray of tiny droplets:

• very large “h” and “A” for HT

Direct air/liquid interface

• Droplets, mist & vapor for HT

Porous media/arrays of heat pipes

• Large HT surface area

• Sea/ocean as heat sink/source

Nano-texturing

• Super-hydrophobic

• Liquid drag reduction and

augment heat transfer

Hydraulic transformer:

• Efficient, power dense

Storage vessel dual used as ballasts or integrate in tower

• @35MPa, Vol=500m3 for 3MW*8hrs, << $120/kWh

Systems Engineering & Optimal Control

• compression/expansion profile

• optimize plant wise control

Hydrostatic Transmission: Reliable (no gearbox), tunable,

optimize turbine speed for energy capture

Contact: Prof. Perry Li

Email: perry-li@umn.edu

Project Challenge & Themes

Major challenge:

• System efficiency and power capability

• Especially in the compressor/expander

Four thrusts:

1. Heat transfer augmentation

–

–

HT surfaces

Droplets, sprays and surface texturing

2. Efficient machines elements

3. Systems, Control and Optimization

4. Integration

6

Fundamental challenge due to

Heat Transfer limitation

Effective compressed air storage / regeneration

requires air motor/compressor that is

• Powerful

• Efficient

• Compact

Without HT

Limited by heat transfer within

air motor/compressor

Adiabatic compression to 210bar = 1260K

Adiabatic expansion from 210bar = 60K

Q: How to optimize efficiency / power-density ?

7

Problem setup

Compression / Expansion Process

2

Assume heat source

& sink at ambient temp T0

2. Cools down to T0 at

constant P to (r P0 , T0)

3. Expansion in tf2 :

(r P0, T0) -> (P0 , T2)

3

Pressure

1. Compression in tf1

(P0 , T0) -> (r P0 , T1)

1

final pressure, Pfinal = r P0

Compression

Expansion

isothermal

Initial pressure, P0

Volume

8

Efficiency/Power trade-off in

Compressor and Expander

• Deviation from isothermal

compression/expansion wastes energy

• Multi-stage (n >> 1) approximates

isothermal but more complex

• Slowing down process increases efficiency

but reduces power density

9

Thrust 1: Heat transfer augmentation

a) Liquid piston / surface area augmentation

b) Liquid Spray

Method:

– Geometry of HT surfaces

– Nozzle design

– Control

Computation,

Analysis,

Experiments

10

Low Pressure (10bar) Liquid Piston Experiment

Test facility - cylinder filled

with air and pressurized

with a liquid piston

11

Micro-tube (large L/D)

Upper

plenum

(c) t*=0.3

(a) t*=0.1

Small L/D

g

Inner

channel

Outer

channel

Solid

Tube

(f) t*=0.4

(h) t*=0.8

• Rich in vortices

• Strong 2nd ary flow (left)

U(t)

• Liquid level rise at different

rates in inner and outer tubes

• Need interrupted channels

HT Surface Augmentation

With HT augmentation

Without augmentation, pressure

decreases as air returns to

Ambient temp

Linear compression rate

89% Improvement!

Without augmentation:

With augmentation

ΔT = 111 +/- 3.5 K

ΔT = 12 +/- 2.2 K

Result should be even better with optimal profile!

13

Optimal Compression/ Expansion trajectories

Improves Efficiency/Power Trade-off

Pareto optimal frontier

3 to 5 times increase in

power for same efficiency

over ad-hoc profiles !

Multi-disciplinary Research

Heat Transfer

Machine Design

Fluid Mechanics

Surface

Texturing

!"#$"%&' "()*+&

, "-&. */ 0-1((*-23405+%1-6&

!

! " #$%&'() *%" +, --$*. (/+&0, 1#*+2((

"!!!!!!#$%&'() '%*!+, - !$. +') /0!- &&'1'- %12!345!. $6 - (!17(3- !82!- ) . 0$2'%*!+, - !

$. +') /0!1$) . (- 44'$%!. ($&'0- !'%!#9: !/%; !1$) . /(- !+, - !#9: !(- 470+4!6 '+, !

+, - !- <. - 1+- ; !(- 470+!&($) !+, - !, - /+!+(/%4&- (!) $; - 0!!

E'41$74!9('1+'$%!D $; - 0!

Fluid Power

C78- !F - $) - +(2!

G!

@$6 - (!

=$03'%*!+, - !

>- 0/+- ; !? . +') /0!

#$%+($0!@($80- ) !

? . +') /0!#$) . (- 44'$%!

C(/H- 1+$(2!

#9: !=') 70/+'$%!

J &&'1'- %12!

345!

@$6 - (!

Systems and Control

http://www.me.umn.edu/~lixxx099/EFRI_CAES

A) . ($3'%*!+, - !

B- /+!C(/%4&- (!

D $; - 0!

@(- 447(- I!C- ) . - (/+7(- I!E$07) - !

15

Key areas of technology

• Near isothermal high pressure

compression/expansion

• Heat transfer augmentation

• Control to affect system trade-off between

efficiency and power

• Efficient machine elements

• Fluid mechanics of nozzle sprays

• Hydro-phobic HT surfaces

16

Li et al. Near Isothermal Compressed Air Energy Storage Approach For Off-Shore Wind Energy using an Open Accumulator

Stores energy locally before conversion to electricity

•Downsize generator and transmission line

Open accumulator:

• Constant pressure

• Liquid port -> high power/low energy path

• Air port -> low power/high energy path

=> Downsize air compressor/expander

Multi-Disciplinary Research

• Heat transfer

• Fluid Flow

• Nano-textured surfaces

• Machine Design

• Fluid power

• Systems dynamics & control

Liquid Piston Near-isothermal air

compressor/expander

Active spray of tiny droplets:

• very large “h” and “A” for HT

Direct air/liquid interface

• Droplets, mist & vapor for HT

Porous media/arrays of heat pipes

• Large HT surface area

• Sea/ocean as heat sink/source

Nano-texturing

• Super-hydrophobic

• Liquid drag reduction and

augment heat transfer

Hydraulic transformer:

• Efficient, power dense

Storage vessel dual used as ballasts or integrate in tower

• @35MPa, Vol=500m3 for 3MW*8hrs, << $120/kWh

Systems Engineering & Optimal Control

• compression/expansion profile

• optimize plant wise control

Hydrostatic Transmission: Reliable (no gearbox), tunable,

optimize turbine speed for energy capture

Contact: Prof. Perry Li

Email: perry-li@umn.edu

17