Gas Compression I

advertisement

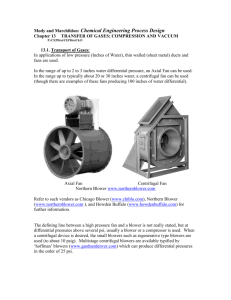

Ref.1: Ikoku, Natural Gas Production Engineering, John Wiley & Sons, 1984, Chapter 5. Ref.2: Menon, Gas Pipeline Hydraulic, Taylor & Francis, 2005, Chapter 4. Ref.3: GPSA Electronic Data Book, Gas Processors Association, 1998, Chapter 13. 1 Gas Compression Type of Compressors Depending on application, compressors are manufactured as positive-displacement, dynamic, or thermal type: 2 Gas Compression Reciprocating Compressors The reciprocating compressor consists of one or more cylinders each with a piston or plunger that moves back and forth, displacing a positive volume with each stroke. They are singleacting or double-acting: Clearance Stroke length Ar = Rod diameter AP = Piston diameter Single-acting Double-acting 3 Gas Compression Reciprocating Compressors Reciprocating compressors have pressure ranges up to 30,000 psi and range from very low HP to more than 20,000 HP per unit. Reciprocating compressors can be single stage or multistage, depending upon the compression ratio required. The compression ratio per stage for positive displacement compressors is limited to 4.0 (because of the valve life and discharge temperature). Gas cylinders are generally lubricated, although a non-lubricated design is available when warranted. Typically, high-speed compressors operate at speeds of 900 to 1200 rpm and slow-speed units at speeds of 200 to 600 rpm. 4 Gas Compression Reciprocating Compressors On multistage machines, intercoolers may be provided between stages. These are heat exchangers which remove the heat of compression from the gas and reduce its temperature to approximately the intake compressor temperature. 5 Gas Compression Centrifugal Compressors Centrifugal compressors develop the pressure required by the centrifugal force due to rotation of the compressor wheel that translates the kinetic energy into static pressure of the gas. Centrifugal compressors can be used for outlet pressures as high as 10,000 psia, and inlet capacity of more than 100000 cfm. Centrifugal compressors are usually either turbine or electric motor driven. Typical operating speeds for centrifugal compressors in gas transmission applications are about 14,000 rpm for 5000-hp units and 8000 rpm for 20,000-hp units. In gas pipeline applications a compression ratio of 1.5 to 2.0 is usually used. 6 Gas Compression Centrifugal Compressors A compressor body may hold one or several (up to 8 or 10) stages. A compressor train may consist of one or multiple compressor bodies. Pipeline compressors are typically single body trains, with one or two stages. 7 Gas Compression Advantages of a Reciprocating Compressor Ideal for low volume flow and high-pressure ratios High efficiency at high-pressure ratios (about 4) Relatively low capital cost in small units (less than 3000 hp) Less sensitive to changes in composition and density Have flexibility in pressure range, and can deliver compressed gas at a wide range of pressures 8 Gas Compression Advantages of a Centrifugal Compressor Ideal for high volume flow and low head Simple construction with only one moving part High efficiency over normal operating range Low maintenance cost and high availability Greater volume capacity per unit of plot area No vibrations and pulsations generated 9 Gas Compression Compressor Selection and Rating A Gas engineer in the field is frequently required to determine the desired specifications of a new compressor station or selecting the operating point of an existing one. These specifications are: Type, number of stages, arrangements (parallel, series, inter and after coolers), driver, speed, efficiency, power and/or capacity of each stages or units, duty of coolers. For determining the above specifications, these parameters are required: Gas Composition(or specific gravity), inlet temperature and pressure, total pressure ratio and total gas flow rate. 10 Gas Compression Compressor Head and Power There are three ways in which the thermodynamic calculations for compression can be carried out — by assuming: 1. Isentropic process, PV k = constant, k = isentropic factor 2. Polytropic process, PV n = constant, n = polytropic factor 3. Isothermal process, PV = constant > W P2 V dP P1 11 Gas Compression Compressor Head (Isothermal) Head ( H it ) Isothermal PV C V C P H it C W m dP m P1 ln( r ), Where r m P1V1 C z 1 nRT 1 H it ft lb f H it lb m V P2 P2 P1 z 1 RT 1 M ln( r ) g 53 . 28 z 1T1 ( o R ) ln( r ) g 12 Gas Compression Compressor Head (Isentropic and Polytropic) PV H is k C C V P C P1 1/ k 1/ k H is C 1/ k m P2 P 1 / k dP P1 k 1 P1 z 1 RT 1 k 1 r m ( k 1) / k M g ( k 1) / k ft lb f H is lb m k 1 53 . 28 z 1T1 ( o R ) k r 1 g ( k 1) / k ft lb f H p lb m n 1 53 . 28 z 1T1 ( o R ) n r 1 g ( n 1) / n k 1 k 1 r 13 Gas Compression Compressor Horsepower Gas Horsepower ( GHP ) Ideal Horsepower Compressio n Efficiency it Isothermal Efficiency Compressio n Efficiency ( c ) : is Isentropic Efficiency p Polytropic Efficiency Brake Horsepower ( BHP ) GHP Mechanical losses GHP m 14 Gas Compression Gas Horsepower GHP ( hp ) ft lb f Head lb m lb Mass flowrate m min 33000 c Mass flowrate q g sc g sc q g sc g 0 . 0764 GHP 8 . 57 10 5 5 z av T1 ( R ) q g sc ( Mscfd ) k 1 k r 1 is ( k 1) / k o 5 z av T1 q g sc n 1 8 . 57 10 z av T1 q g sc n r 1 ln r p ( n 1) / n it 8 . 57 10 15 Gas Compression Isentropic and Polytropic Efficiency k 1 1 k r 1 ( n 1) / n is ( k 1) / k p 1 n 1 n r 1 Fig. 13-37 k 1 p ( k 1) / k ( n 1) / n r is k cv cp cp R yc , y c R i i pi pi 1 ( k 1 ) / k r cp k p 1 For natural gas : k 150 o F 2 . 738 log( g ) 2 . 328 16 Gas Compression Discharge Temperature 1/ k C k k 1 PV C , V T2 P2V 2 z 1 z 1 k r P T P V z z 1 1 1 2 2 PV z n RT z1 r T 2 T1 z 2 is T 2 T1 is T 2 T1 real k 1 k z 1 k 1 k r 1 T 2 T1 z 2 T1 17 18