Nieuws - Oostrozebeke

advertisement

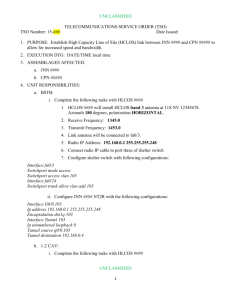

Cost Efficient Manufacturing of Silicide Thermoelectric Materials and Modules using RGS Technique (b) A. 1 Schönecker , 1 Kraaijveld , 2 Til , 3 Brinks , B. A. E. van P. 2 3 1 A. J. Böttger , M.Huijben , M. den Heijer 1RGS Development B.V., Bijlestaal 54a, 1721 PW Broek op Langedijk, The Netherlands 2Delft University of Technology, Mekelweg 2, 2628 CD Delft, The Netherlands 3MESA+ Institute for Nanotechnology, University of Twente, 7500 AE Enschede, The Netherlands INTRODUCTION To harvest the promise of thermoelectric (TE) power generation at higher temperatures in the area of industrial waste heat recovery a number of challenges must be met: - TE system requirements - Financial return of investment period of less than 3 years No disturbance of industrial manufacturing process Environmentally benign, low maintenance system CHROMIUM DOPED HIGHER MANGANESE SILICIDES (HMS) Samples Material composition (%wt.) Si Mn 52% 48% 50.2% 47.3% 48.1% 39.4% 75-8NA, 75-10NA 76-9NA, 76-10NA 77-8NA, 77-10NA MnSi1.74 Cr0.05Mn0.95Si1.74 Cr0.25Mn0.75Si1.74 Structure - TE module requirements - Cr 0% 2.5% 12.5% Modules for high temperature application Module design adaptable to system requirements -TE material requirements - Lowest cost, stable, environmentally benign materials Reasonable ZT values OBJECTIVES AND APPROACH The objective is to develop thermoelectric materials and modules that can be used in high temperature industrial waste heat recovery applications. By the use of the ribbon-growth-on-substrate (RGS) casting process: - To produce thermoelectric legs in a low cost, single step process; - With stable and proven silicide compositions; - In a flexible net shape format. By development of a low cost TE module concept that: - Operates in a high T environment (T > 500oC); - Can be manufactured easily; - Allows versatile module design to meet system requirements. XRD spectrum and SEM cross sections of HMS samples with 0%, 2.5wt%, and 12.5wt% Cr. While lower Cr concentrations (a), (b) only show a Si and a HMS phase, the 12.5wt% Cr sample (c) also shows a CrSi2 phase. TE Characteristics MATERIAL AND MODULE MANUFACTURING A Single Step TE Leg Casting Sample k [W/(m·K)] at T=300K 75-10NA 2.20 MnSi1.74 76-9NA 3.33 Cr0.05Mn0.95Si1.74 77-8NA 3.35 Cr0.25Mn0.75Si1.74 Comparison with Literature Values Sample RGS technique replaces multiple material manufacturing steps by a single step direct casting process. Strip Based TE Module Manufacturing (a) (b) [1] [2] 75-10NA [1] [1] 76-10NA [2] [2] 77-8NA Cr at% ZTmax TZTmax [K] S [mV/K] 0 0.36 0.28 0.26 0.6 0.56 0.46 0.39 0.52 0.51 850 900 825 850 850 883 900 900 883 190 250 258 200 200 227 180 150 159 0.03 0.05 0.10 0.20 0.25 s [S/cm] k [W/(m·K)] 312 200 117 455 455 338 280 580 655 2.9 3.5 2.5 2.5 2.7 3.3 3 3 3.5 MnSi1.74 Cr0.03Mn0.97Si1.74 Cr0.05Mn0.95Si1.74 Cr0.10Mn0.90Si1.74 Cr0.20Mn0.80Si1.74 Cr0.25Mn0.75Si1.74 CONCLUSIONS RGS material casting technology: - is an ideal platform to produce metal silicide TE materials in net-shape form. - is low cost, industrial scale, single step process. - is capable of producing HMS materials with competitive ZT values. In combination with a low-cost, strip based TEG module concept for high temperature industrial waste heat recovery, a strong cost reduction for TE power generation is possible. REFERENCES Net shape strip casting of RGS materials (a). Conceptual design of the active components of a TEG module made from strip shaped legs. (b) Thermal module concept to test operation temperature and material stability. [1] Y. Miyazaki, Y. Saito, K. Hayashi, K. Yubuta, and T. Kajitani, Japanese Journal of Applied Physics, Vol. 50, p. 035804, 2011 [2] Y. Kikuchi, Y. Miyazaki, Y. Saito, K. Hayashi, K. Yubuta, and T. Kajitani, Japanese Journal of Applied Physics, Vol. 51, pp. 1–5, 2012