view - George Washington University

advertisement

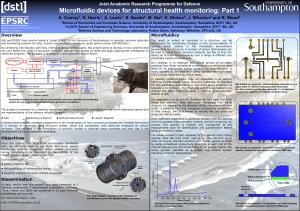

CMOS and Microfluidic Hybrid System on Chip for Molecule Detection Bowei Zhang, Qiuchen Yuan, Zhenyu Li, Mona E. Zaghloul, IEEE Fellow Dept. of Electrical & Computer Engineering, The George Washington University SPAD Breakdown Simulation Background and Motivation Scientific and Medical Fluorescence Image System needs to detect very weak photon signal Lost Energy hc E= Time Delay f (t ) = a e Lifetime Lifetime Wavelength (1/ ) t Fluorescence excitation process Traditional image system use 3 filters at each pixel to identify different wavelength, which waste 2/3 of the photon signal. lifetime image system doesn’t need filter. Each pixel use lifetime to distinguish signals. Sensitivity can be improved about 3 times. SPAD Design & Modeling For fluorescence image system, signal photon avalanche diode(SPAD) can be used as the photon detector. It not only can detect the photon numbers, but also can detect the fluorescence lifetime. We used the CMOS 0.5μm technology to design and fabricated the SPAD. The top view of our design is as shown in Fig.1 (a). A center n-well and a surrounding n-well were designed with certain gap between each other . The guard ring gap can protect SPAD from perimeter breakdown. A p+ doping is designed to cover the center n-well to form a p+n- juction, which is the area to detect photons. Fig.1(a) SPAD design top view For p+/n- junction photodiode, when the p+ doping density fixed, the lower the ndoping density, the higher the breakdown voltage. When the doping density at the perimeter area of the photodiode is low enough, the junction would breakdown at the center area first. Therefore, by control the gap between two n-wells, a low doping n- guard ring can be created to prevent the perimeter breakdown. Fig. 2&3 show the simulation results. Fig.2(a) Simulated current density with proper n-wells gap(1.8um) Quenching Circuit for SPAD When a photon arrives, SPAD breakdown, a quenching circuit is required to pull down the reverse voltage after an avalanche event, and after the recombination of the electron in the junction, the quenching circuit will apply a high reverse voltage on the SPAD again to ready for detecting another photon. CMOS & Microfluidic Integration “Delay control signal” controls the rising delay of a slow rise inverter, which could adjust the output pulse width Traditional fluorescence image system is complex and relative big. To build a portable system, we want to integrated the CMOS & Microfluidic technology. The hybrid CMOS & Microfluidic system is much smaller compare with traditional optics setup. It also have the potential to reach the similar sensitivity as the traditional setup. we use the material call polydimethylsiloxane (PDMS) to make the Microfluidic channels. PDMS is a soft polymer widely used in microfluidic and micro-optics due to its low cost, easy fabrication process, bio-compatibility and optical transparency. 10μm Layout design of Dynamic Quenching Circuit Fabricated CMOS Dynamic Quenching Circuit Fig.2(b) Simulated current density, when n-wells gap too small, breakdown happened at perimeter Design diagram of hybrid CMOS & Microfuidic System. Microfluidic channels are used for electrical interconnection and sample delivery Fig.3(a) Simulated I-V character of SPAD Fig.3(b) Simulated quantum efficiency Fabrication of SPAD in CMOS After simulation, SPAD, Quenching circuit and I/O Pads are designed in CMOS technology. The layout of the chip design was sent to semiconductor manufacturing company for fabrication. Output from Dynamic Quenching Circuit Each pulse indicate one photon event Each pulse has around 45ns pulse width FPGA Counting System FGPA counting system is design to count the total number of signal pulse from the quenching circuit, which indicates the total photon number in certain accumulation time. In addition, Time-to-Digital Converter (TDC) is designed on FGPA to record the photon arrive time. Which can be used to generated the fluorescence lifetime after signal processing. CMOS Foundry 500μm Layout of our SPADs design Silicon Wafer 100μm 80um microfluidic channel delivering low melting point solder 200μm Preliminary CMOS & Microfluidic Hybrid System The key innovations of this method are: 1. using microfluidic channel to delivery low melting point solder for CMOS die and PCB board bonding. 2. PDMS Microfluidic channela put test sample directly contact with CMOS sensor chip to achieve high signal collection efficiency, thus improve the sensitivity. Fabricated chip of SPAD design Altera Cyclone II FGPA board used for design counting system. The figure on the right shows the basic function of Time correlated Single Photon Counting (TCSPC), which embedded in FPGA Fig.1(b) Device doping profile model based on CMOS 0.5 μm Technology . f (t ) = a e (1/ )t Coated micro-beads that can catch target molecule and generate fluorescence signal. 25μm 9 SPAD Designs with different Guard Ring Gap length Two samples with different fluorescence lifetime Microbead fluorescence signal in preliminary experiment. A microfluidic channel trap is designed to catch a 10um diameter micro-bead with fluorescence signal. Our further work is to integrate this trap right on top of the SPAD Contact Information Fig.1(c) Device electric field profile. High electric field area easier to breakdown. Measured I-V character of one of the fabricated SPAD with proper guard ring gap length(1.8um) Measured I-V character of one of the fabricated SPAD with wrong Gap length 20μm Bowe Zhang, email: bowei@gwmail.gwu.edu