Ideal for Thickness Survey / Corrosion Monitoring

advertisement

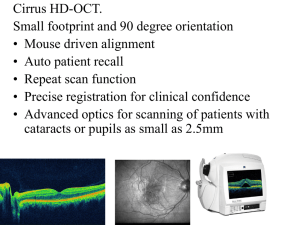

Salient Features of ‘da Vinci alpha’ / ‘da Vinci delta’ Digital Ultrasonic Flaw Detector Ideal for Thickness Survey / Corossion Monitoring Ideal for Thickness Survey / Corrosion Monitoring Test Range Starts from 2.5mm (in steel) • Better resolution / accuracy on lower thickness. Ideal for Thickness Survey / Corrosion Monitoring Measurement Resolution of 0.01mm • Better Measurement Accuracy Ideal for Thickness Survey / Corrosion Monitoring Encoded B-Scan • Shows in graphical presentation cross-section of object thickness for easy identification of high corrosion. Ideal for Thickness Survey / Corrosion Monitoring Encoded B-Scan • Encoded x-axis data gives the precise location of each thickness measurement from a reference point . Ideal for Thickness Survey / Corrosion Monitoring “Minimum Thickness” Scan Mode • This scan mode enables detection of minimum thickness (highest corrosion) in each scanning. Ideal for Thickness Survey / Corrosion Monitoring Memory of Thickness Measurement Data • 20,000 thickness measurements. • 50 B-scan (of 500 readings each). Ideal for Thickness Survey / Corrosion Monitoring ‘dvaSoft’ Software for Thickness Data Management For • Sequential • 2D and 3D configured file generation. Ideal for Thickness Survey / Corrosion Monitoring Echo-Echo Measurement • To eliminate / ignore coating thickness from thickness measurements. Ideal for Thickness Survey / Corrosion Monitoring Two Independent Thickness Measurements • Two monitor gates offer independent thickness measurements to enable ‘High’ and ‘Low’ thickness alerts. High End, Accurate & Convenient Flaw Detection ToFD - Time of Flight Diffraction • Simple single channel ToFD feature. * Available in ‘da Vinci delta’ ToFD • Display : In Real-Time RF A-Scan & ToFD D-Scan. • Recording : Free Run or with positional Encoder for actual location. • Record Length : 1000mm test length with collection step of 1mm. Each A-Scan with 500 point depth. • Data Storage : Each Scan file is stored in external USB storage device with auto file naming. ToFD Data Analysis Software • Straightening of ToFD data using apex matching technique or by manually shifting of A-Scan is possible. • Defect marking of D-Scan image. • D-Scan data zooming control. • All A-Scan data can be exported to Excel for further analysis. High End, Accurate & Convenient Flaw Detection Colour Legs • Colour-coded display of legs during weld examination (angle probing) helps operator to identify skip distance. High End, Accurate & Convenient Flaw Detection Active Peak Echo Dynamic • Echo dynamic envelope generated in red colour in the back ground with active / live A-scan in fore ground in different colour helps operator to identify the defect type. High End, Accurate & Convenient Flaw Detection Curved Surface Correction • Trigonometric measurements while using angle probe on curved surface is accurate due to correction applied. International Standards Compliance for Flaw Size Evaluation First Echo / Interface Echo Triggering • This is useful during Immersion Testing. High End, Accurate & Convenient Flaw Detection Four Narrow Bands • • • • a) 0.2 MHz – 1 MHz b) 0.5 MHz – 4 MHz c) 0.8 MHz – 8 MHz d) 2.0 MHz – 20 MHz • Tuned amplifier gives high Signal / Noise ratio. High End, Accurate & Convenient Flaw Detection RF Display • Radio Frequency (RF) display for very high degree of measurement accuracy, probe characteristics evaluation and flaw characterization. High End, Accurate & Convenient Flaw Detection Automatic Test Range Calibration • It is faster, more accurate and easier than manual calibration. High End, Accurate & Convenient Flaw Detection Pulse Repetition Frequency (PRF) • It is possible to set PRF as low as 4 Hz to eliminate phantom / ghost echoes while testing large forgings etc… High End, Accurate & Convenient Flaw Detection Simultaneous Display of Four Measurement Values • Selection of upto four measurement values for simultaneous display helps the operator in quick interpretation. High End, Accurate & Convenient Flaw Detection Wide Frequency Range (250 KHz to 20 MHz) • Frequency down to 250 KHz (0.25 MHz) enables testing of highly attenuative materials like composites, austenitic stainless steel etc.. • Probe with frequency up to 20 MHz on higher side can be used for checking low thickness jobs and for enhanced sensitivity. International Standards Compliance for Flaw Size Evaluation International Standards Compliance for Flaw Size Evaluation DAC Curves Complies with ● ASME ● ASME III Standards ● JIS International Standards Compliance for Flaw Size Evaluation DAC Curves • Multiple Curves with user selectable dB intervals (1dB to 14 dB). • Any of the curves can be set to trigger as flaw monitor gate. Large on-board memory and virtually unlimited memory thro’ USB removable disc. Memory On-Board • 500 A-Scan data. • 20,000 Thickness data. • 50 Set-up data. • 50 B-Scan data. Memory USB Removable Disc • Just hook up USB removable disc (pen drive) up to 8GB capacity and have virtually unlimited data storage capacity. Speedy data communication, user friendly mechanical features and most reliable power supply. Communication, Mechanical Features and Power supply USB Port • For speedy and reliable data communication with PC and peripherals. Communication, Mechanical Features and Power supply VGA Output • Thro’ VGA port hook-up ‘da Vinci alpha’ to a PC monitor or LCD projector for remote and multiple viewership. Communication, Mechanical Features and Power supply Rotary Scroll Knobs • Ergonomic scroll knobs are very user friendly, speedy and lends analogue feeling to the operation. With the knob on left ‘ Gain ‘ can be adjusted and with the one on right the selected parameter can be changed. Communication, Mechanical Features and Power supply Display Back Ground Colours • Choose the colour combination to suit the environment and your personal preference. Communication, Mechanical Features and Power supply IP Sealing • All the mating joints are gasketed for protection against water splash and dust. Communication, Mechanical Features and Power supply Carrying Handle Cum Stand • Six Different positions of the stand for convenient viewing which doubles up as a carrying handle. Communication, Mechanical Features and Power supply Neck Strap • For hands free operation. Communication, Mechanical Features and Power supply Li-Ion Battery • World-class (Made in USA) high capacity Li-Ion battery (10.8VDC, 7.8AH) gives 8 hours of continuous operation between the charges . • The battery has built-in LED charge indicator. • Battery compartment has ‘quick release fasteners’ for easy and quick replacement of battery. Communication, Mechanical Features and Power supply Alkaline Batteries • In emergency ‘da Vinci alpha’ can be operated for about 3 hours on six C size alkaline batteries. Communication, Mechanical Features and Power supply Charging the Battery • Special Charging circuit is built inside ‘da Vinci alpha’. Plug-in the supplied AC adaptor to charge the battery within four hours. • Optionally special charger is available to charge the battery out side the machine. Pulser / Receiver Characteristics of ‘da Vinci alpha’ Pulser/Receiver Characteristics Dead Zone / Near Surface Resolution • Normal Probe: 10Mhz x 10mm dia. • Reflector : 1mm step Pulser/Receiver Characteristics Dead Zone / Near Surface Resolution • TR Probe: 5Mhz x 10mm dia. • Reflector : 2mm step Pulser/Receiver Characteristics Dead Zone / Near Surface Resolution • Angle Probe: 4Mhz, 8x 9mm ,45 deg. • Reflector : 1.5mm SDH at 15 depth. Pulser/Receiver Characteristics Far Surface Resolution • Normal Probe: 4Mhz, 10mm dia. • Reflector : Resolution notch on V1 Block. Pulser/Receiver Characteristics Sensitivity/ Signal to Noise Ratio • Normal Probe: 4Mhz, 10mm dia. • Reflector : 1/64” FBH in Aluminium ASTM Block Pulser/Receiver Characteristics Penetration Power • Normal Probe: 2Mhz X 24mm dia. • Reflector : Perspex insert in V1 block • Total no of back reflections are 5 full and 6th about 50%. Pulser/Receiver Characteristics Noise • Total noise <10% at full gain setting. Thank You !