G. Palasantzas - Physics @ IUPUI

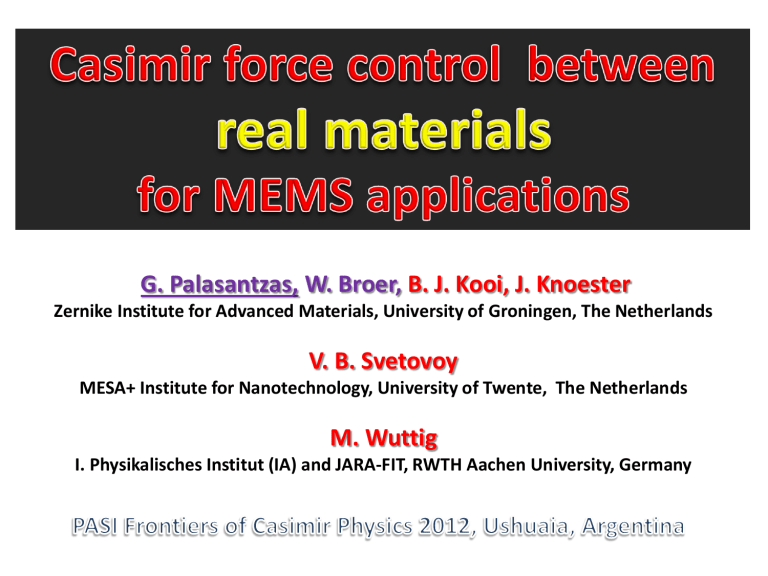

G. Palasantzas, W. Broer, B. J. Kooi, J. Knoester

Zernike Institute for Advanced Materials, University of Groningen, The Netherlands

V. B. Svetovoy

MESA+ Institute for Nanotechnology, University of Twente, The Netherlands

M. Wuttig

I. Physikalisches Institut (IA) and JARA-FIT, RWTH Aachen University, Germany

60 groups

11 countries

Boesel et al., Advanced Materials 2010

If all 6.5 million setae of one gecko toes attached simultaneously it lifts 30-40 kg

….am I a “”Drude”gecko or

.… a “plasma”….one…

Stanford researchers with the Stickybot

Geim et al., Nature Materials 2003

A photo showing a stainless steel adapter of 473 g hanging on a SiO2/Si-wafer supported vertically aligned SWCNT dry adhesive film (4mm x 4mm) http://www.nanowerk.com/spotlight/

Kwak et al, Advanced Materials 2011

Quantum engine cycle between two Casimir force states – tap energy from vacuum (F. Pinto PRB 1999)

Stiction & Levitation

Intersting idea but…..no clear force contrast !

Chen et al, Opt. Express 2007, PRB 2007

Chang et al., PRL 2011, PRB 2012

A laser beam heats the PCM above the melting temperature & Rapid quenching glass-like amorphous state

heating the amorphous phase with moderate intensity laser beam: amorphous state more stable crystalline phase

This principle has already been successfully employed in three generations of rewriteable

(RW) optical data storage ( CD, DVD, BD )

Pandian et al.,

Adv. Materials 2007

Pandian et al.,Adv. Materials 2007

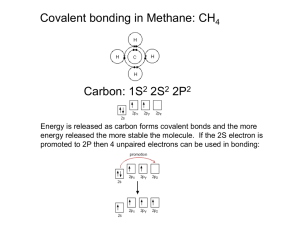

Crystallization is accompanied by the formation of resonance bonds

Change of bonding mechanism affects the optical properties in the visible & UV range

So far no other materials have similar change of optical properties upon crystallization

Crystallization generates of a large amount of free carriers affecting the IR range

The situation in which a single, half-filled p-band forms two bonds to the left and right more than allowed by the 8-N rule (N valence) was coined as resonant bonding by Pauling.

electron delocalization characterizing resonant bonding increased electronic polarizability a fingerprint of resonance bonding

Free carriers /Drude

0 .

07 eV,

(

)

8 .

9 eV,

(

)

C

Resonant bonding

i (

2 p

A /

3

/

)

relevant for optical data storage : photon energies between

1.5 eV

(compact discs) - 3 eV (blu-ray disk) are employed

Phys. Rev. A 2010, New Scientist July 2, 2010 (interview with Eugene Reich)

Casimir force upon crystallization is due to the change of the dielectric function

• in the infrared regime (free carriers) ……?

• or in the visible-UV range (resonance bonding)….?

• Or both and how much they contribute ?

0 .

07 eV,

(

)

C

i (

2 p

/

)

8 .

9 eV,

(

)

A /

3

Extrapolation

2 p

/

|

AIST

10 .

6 for

0 .

07 eV

Compare to ITO :

2 p

/

|

ITO

17

Compare to Au :

2 p

/

|

Au

1600

Crystalline PCM: free carriers in many cases (

10 20 /cm 3 )

But have very small mean free paths, even below

3 nm

We substracted form the crystalline phase the Drude contribution…….

Two strategies to maximize the force contrast upon crystallization of phase change materials:

• employ materials with particularly strong resonant bonds (PCM with low iconicity and low hybridization of s- and p-states)

• small disorder and large carrier concentration to ensure a large Drude contribution

…plethora of issues to be resolved to make a device…..

Take roughness contributions for both Casimir and electrostatic forces……

Broer et al, EPL 2011, PRB 2012

Broer et al, EPL 2011, PRB 2012

Flat surface Pertubative term

Peak contribution

V eq Cas z

F el z

No electrostatic force (V=0)

in certain situations typically two equilibria occur:

• a stable center around which periodic solutions exist,

• unstable saddle point

=0

(z)=(1-z/L o

)(F

L

(L o

)/F

Cas

(z)

[

(z)/

cas-1]Fcas(z)=0

(z)/= cas

: Bifurcation parameter

electrostatic force absent (V=0 V)

L o

=100 nm Stable region

PCMS are promissing for Casimir engines .....more research is needed to fabricate materials to have larger force contrast Two strategies to maximize force contrast of PCMs:

• employ materials with particularly strong resonant bonds (low ionicity and low s-p hybridization)

• small disorder and large carrier concentration to ensure a large

Drude contribution

Surface roughness strongly influences actuation dynamics and proper roughening can benefit systems against stiction/pull-in instabilities (see poster W. Broer) .... ............take into account hydrodynamic forces for rough surfaces... Work in progress