Document

advertisement

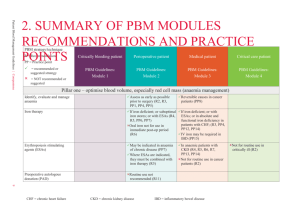

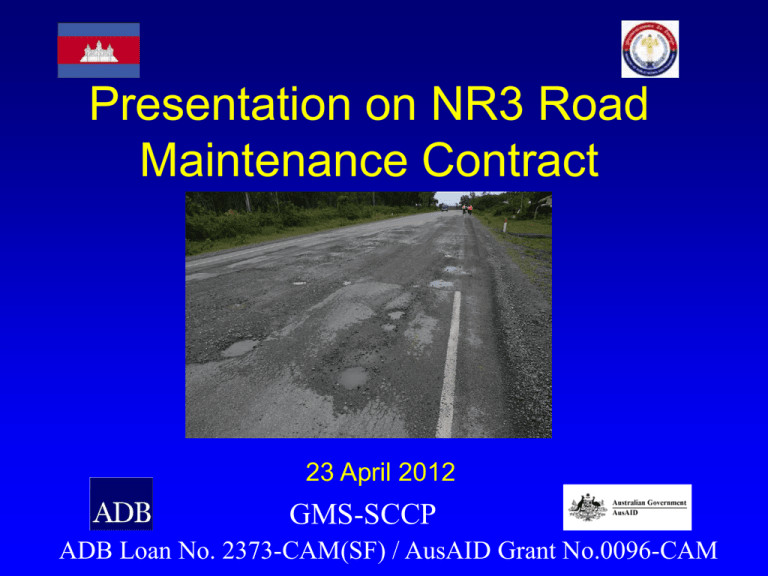

Presentation on NR3 Road Maintenance Contract 23 April 2012 GMS-SCCP ADB Loan No. 2373-CAM(SF) / AusAID Grant No.0096-CAM MPWT/PMU3 Egis International CS Consultant Mr. Chhin Kong Hean Project Coordinator Mr. Andre Drockur Project Manager Mr. Pheng Sovicheano Project Director Mr. Khagnh Sitnarit Highway Engineer/NTL Mr. Sar Vutha Project Manger Table of Content 1. 2. 3. 4. 5. 6. 7. Project Location Map General Data of NR3 NR3 Road Inventory Road Condition Survey Policies for the Maintenance of NR 3 Important technical requirements to be met General Concept of Performance Based Routine Maintenance (PBM) 8. Service Quality Levels and General Aspects of the Road Covered in PBM Contract 9. Specs for Performance Based Routine Maintenance (PBM) 10. Involvement of Private Sector for PBM 1. Project Location Map 2. General Data of NR3 Contract No. Contract Name Type of works, Section and Length CSC Consultant Draft Bidding Documents submitted to MPWT ADB comments on the Draft Bidding Documents Response to ADB regarding their comments ADB approval on the response Bidding procedure Invitation for Bids advertised Deadline for Bids submission Pre-bid meeting Bid evaluation to PMU3 Expected Award/sign Contract SCCP – CW3 Maintenance of NR3, Kampot to Veal Rinh Quantity and unit-priced maintenance works on road section Km 12+300 to Km 32+850 (22.55km). Performance/output based routine maintenance for two years on two sections: Km 0+000 to Km 12+300 (12.3km) and Km 32+850 to Km 54+300 (21.45km). Egis International in association with KACE, KCC, KCEC, SBK and VIDO. 04 November 2011 06 January 2012 17 January 2012 20 January 2012 National Competitive Bidding 25 January 2012 16 March 2012 08 February 2012 20 April 2012 15 June 2012 3. NR3 Road Inventory • Standard: National Road • Age: +/- 5 years • Construction value: 335,000 $/km (reference: year 2006) • Width: 7 m carriageway + 2 x 1.5 m shoulder • Pavement: 0.20 m sub-base 0.20 m granular base 0.03 m DBST • Structures: concrete, non-critical • Traffic control devices: in need of improvement • Geological conditions: agricultural terrain • Land use: villages, farmland 4. Road Condition Survey The inspection of NR3 was undertaken from 11 August 2011 to 16 August 2011 and from 26 September 2011 to 28 September 2011 by a team, composed of MPWT and EGIS Engineers and aimed at: the actual condition of the road, i.e. • defects, • location of defects, • causes of defects, • priorities of remedial work; maintenance of the road, i.e. • actually undertaken works, • work methods, preventive/remedial, • availability of resources; 4. Road Condition Survey (continue) general difficulties, such as: • climatically impact, • drainage facilities, • materials, equipment, staff skills. On the grounds of type, location, number and severity of the identified defects it appears appropriate to consider 3 different sections of the road, i.e. Section 1 km 0+000 – km 12+300 in good condition maintainable under terms of routine maintenance Section 2 km 12+300 – km 32+850 84 severe defects that require pavement restoration repair required to achieve “maintainable” condition Section 3 km 32+850 – km 54+300 15 less critical defects that require patching/sealing repair recommended prior to tendering maintenance. 5. Policies for the Maintenance of NR 3 In order to realize in the future “maintenance” for NR3, it is utmost important to plan appropriate repair measures for each of the 3 above mentioned sections, to coordinate them time-shared and implement them accordingly. Section 1, km 0+000 – km 12+300, is maintainable, apply the performance based routine maintenance from the first year. Section 2, km 12+300 – km 32+850, is not maintainable, apply the repairs at the first year and one year defect liabilities period (plus preserve some money for the repair works of newly defects during DLP). Section 3, km 32+8500 – km 54+300, is maintainable after repaired minor major defects, apply the performance based routine maintenance from the first year even the Contractor has to bear a bit higher maintenance for the first year. 5. Policies for the Maintenance of NR 3 (cont.) Based on the detailed cost estimate, the cost for the maintenance of the 3 sub-sections of NR3 maintenance is relatively small (less than 2 M$), it was decided that the maintenance of the entire NR3 should be tendered out as one NCB package only with the following maintenance scope: Quantity and unit-priced maintenance works on road section (S2) Km 12+300 to Km 32+850 (22.55km), covering the indicative quantities of (i) Roadway Excavation, Common – 9,730 m3, (ii) Embankment – 1,400 m3, (iii) Selected sub-grade – 980 m3, (iv) Sub-base – 2,800 m3, (v) Reconstructed Sub-base – 17,000 m3, (vi) Aggregate base course – 6,930 m3, and (vii) Bituminous Seal Coat 12 mm – 43,500 m2 . The maintenance period is for 1 year + 1 year DLP. Performance/output based routine maintenance on two sections (S1&S3): Km 0+000 to Km 12+300 (12.3km) and Km 32+850 to Km 54+300 (21.45km). The routine maintenance period is for 2 years for both sections. 6. Important technical requirements to be met - The restoration of NR3 shall meet the Specifications used for construction, - Assure proper cutting/jointing/sealing of the repair spots in the course of repair works and maintenance to avoid pavement defects through penetrating water, - Control surface water as efficiently as possible, - Plan, organize condition surveys and maintenance work so that by application of preventive work methods remedial works, that are inconvenient for the road user and expensive for the owner, can be avoided as far as possible. - For NR3-Section 1&3, the works shall be carried out in conformity with Part C of this document the “Performance Based Routine Maintenance Specification”. - For NR3-Section 2, the works shall be carried out in conformity with Part A the "General Specifications" and Part B of this document the "Special Technical Specifications“. 7. General Concept of Performance Based Routine Maintenance (PBM) The PBM contract is different from a traditional quantity and unitpriced-based, short-term maintenance contract. The PBM contract is also different from an operation and maintenance (O&M) concession. Under the PBM contract, performance risks are allocated between the government/client and the contractor. A PBM contract is an agreement between a government department or state enterprise and a private contractor whereby the private contractor maintains the road to achieve specified condition standards for a certain period of time (usually longterm), 2 years in the case of the routine maintenance component of NR3 Kampot to Veal Rinh),in return for a fixed payment stream. 7. General Concept of Performance Based Routine Maintenance (continue) The concept of PBM contracts originated from a consideration of (i) the increasing lack of personnel within the government road departments available to measure the vast quantities of activities involved in the more traditional maintenance contracts, and to monitor performance standards using inputs indicators; (ii) the frequency of claims resulting from the necessity to increase the quantities of activities of the original contracts; (iii) the need to focus more on customer satisfaction; and (iv) the need to shift greater responsibility to contractors throughout the entire contract period, as well as to stimulate and profit from their innovative capabilities. The PBM is especially suitable for low-volume roads with gravel surface or thin bituminous surface treatments as the continued serviceability of such roads depends entirely on the quality and reliability of future maintenance. 8. Service Quality Levels and General Aspects of the Road Covered in PBM Contract Road conditions can be expressed through indicators for service quality levels, and these are used under the performance-based contract to define and measure the desired performance of the Contractor. In the Performance-Based Management and Management Contracts, the service level indicators are thus the accepted minimum thresholds for the quality levels of the roads for which the Contractor is responsible. General Aspects of the Road: Aspect Weight Factor Pavement (potholes, depression, evenness, cleanliness) 5 Roadside slopes (erosion) 3 Clearway (grass, , bushes, branches, litter) 2 Structures (bridge deck, expansion joint, gullies/scuppers) 3 Drainage System (ditches, culverts) 3 2 Signs and Road Safety (pavement marking, km and guideposts etc, ) 9. Specs for Performance Based Routine Maintenance (PBM) Contractors task: Preservation/repair of the contract road to the condition when taken over from owner. The contractor is advised to: Apply preventive work methods to the utmost possible extent to avoid expensive repair work. Undertake pavement condition survey (i.e – Monthly). Undertake road condition survey (i.e – Quarterly). Execute maintenance/repair as per the maintenance manual attached to the contract. Contractors work will be supervised at random and certified by owners inspectors monthly for due payment. Apply Payment Reductions for non-compliance with service quality level . Payment for routine maintenance services shall be “Km-year”. 10. Involvement of Private Sector for PBM Currently in Cambodia, the routine maintenance is performed by force account (In-house). It is hampered by frequent delay of insufficient fund allocation and considered unsatisfactory by MPWT. MPWT through SCCP is currently implementing Performance Based Routine Maintenance (PBM) through the Involvement of Private Sector after road rehabilitation. By contracting PBM to Private Sector, performance risks are allocated between the government/client and the contractor. Proper distribution of maintenance workload among Force Account and Private Sector is required. Type, amount and cost of work as considerable criteria for the selection of the 2 parties. Pro’s and Con’s considering the 2 parties. (In line with the international experience of PBM, especially the high risk of disputes, Private Sector/Contractor with good capacity and experience to manage roads is required). THANK YOU