Electrical actuation systems

advertisement

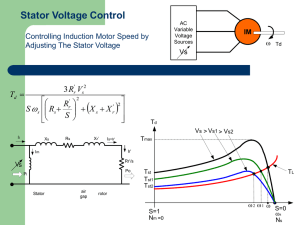

Intro.. Actuator is a device which is used to actuate a process. Actuate is to operate the process. 1. Switching devices – mechanical switches, eg. relay and solid state switches, eg diodes, thyristors and transistors app – switch on or off electrical devices 2. Solenoid – type devices used to actuate valves of hydraulic and pneumatic systems. (flow control) 3. Drive systems – DC motor, AC motor and stepper motor. Basic electronics Semi-conductor Diode Transistor Resistor Electronics specification and abbreviation Expansion of abbreviation British mains wiring name Description One-way A simple on-off switch: The two terminals are either connected together or disconnected from each other. An example is a light switch. Two-way A simple changeover switch: C (COM, Common) is connected to L1 or to L2. Mechanical switches SPST Single pole, single throw SPDT Single pole, double throw SPCO Single pole, centre off DPST Double pole, single throw DPDT Double pole, double throw DPCO Double pole changeover or Double pole, centre off switches with a stable off position in the centre Double pole Equivalent to two SPST switches controlled by a single mechanism Equivalent to two SPDT switches controlled by a single mechanism. Equivalent to DPDT. Some suppliers use DPCO for switches with a stable off position in the centre Symbol Mechanical switches Relay - A relay is an electrically operated switch. Relay Electrically operated switches in which changing the current in one circuit switches a current on or off in another circuit. NO – normally open , NC – normally closed Output from controller is small so it is often used with transistor. Relays are inductances Free – wheeling or fly back diode. Importance To operate a device which needs larger current. solenoid Solenoid is an electromagnet which can be used as an actuator. Electrically operated actuators. Solenoid valves are used in hydraulic and pneumatic systems. Relay Solid state switches diode Transistor Thyristor Triac Bipole transistor MOSFET Diode Bipolar Transistors Transistors are manufactured in different shapes but they have three leads (legs). The BASE - which is the lead responsible for activating the transistor. The COLLECTOR - which is the positive lead. The EMITTER - which is the negative lead. Transistor as a switch Bipolar switch Darlington pair Transistor needs large base current to switch on. Output from microprocessor has a small input. A second transistor is employed to enable a high current to be switched on. Such a combination of pair of transistor is called Darlington pair. MOSFET Metal oxide field effect transistor Two types N channel P channel Three terminals Gate (G) Drain (D) Source (S) Operation When MOSFET is turned on current flows from source to drain . Voltage is applied between gate-source to turn on MOSFET. MOSFET can be turned off by removing gate voltage. Gate has full control over the control of MOSFET. A level shifter buffer required to raise the voltage level at which the MOSFET starts to activate. Interfacing with µp is simpler then transistor. Thyristor Thyristors have three states: Reverse blocking mode — Voltage is applied in the direction that would be blocked by a diode Forward blocking mode — Voltage is applied in the direction that would cause a diode to conduct, but the thyristor has not yet been triggered into conduction Forward conducting mode — The thyristor has been triggered into conduction and will remain conducting until the forward current drops below a threshold value known as the "holding current" Triac Voltage control Thyristor dc control Lamp dimmer Thyristor dimmers switch on at an adjustable time (phase angle) after the start of each alternating current half-cycle, thereby altering the voltage waveform applied to lamps and so changing its RMS effective value. R1 is a current limiting resistor and R2 is a potentiometer. By adjusting R2 thyristor can be made to trigger at any point between 0 deg and 90 deg. Snubber circuit In order to prevent sudden change in source voltage, the rate voltage changes with time is dV/dt is controlled by using a snubber circuit. Drive systems DC motor AC motor Stepper motor DC motor Working principle When current passes through the coil, the resulting forces acting on its sides at right angles to the field cause forces to act on those sides to give a rotation. For the rotation to continue, when the coil passes through the vertical position the current direction through the coil has to be reversed. Parts Stator (permanent or non permanent magnet) Rotor (electromagnet) Armature Commutator Brush A brush type dc motor is essentially a coil of wire which is free to rotate - termed as rotor in the field of permanent or non-permanent magnet. The magnet termed a stator since it is stationery. For the rotation to continue, when coil passes through vertical position the current direction is reversed which is got by use of brushes making contact with split ring commutator. For an armature conductor of length l and carrying a current I, the force resulting from a magnetic flux of density B at right angles to the conductor is given by F = BIL Torque produced along the axis of the conductor due to force F is T=Fxb = nBIL x b = KI Since armature is a rotating magnetic field it will have back emf Vb. The back emf depends on rate of flux induced in coil. Back emf is proportional to angular velocity w Vb = Kw Equivalent circuit diagram for D.C motor Ra V a La = inductance Vb Neglecting the inductance produced due to armature coil, then effective voltage producing current I through resistance R is Va-Vb, hence I = (Va - Vb)/R = (Va – Kw)/R T=KI = k(Va – Kw)/R Control of brush type DC motor Speed control can be obtained by controlling the voltage applied to the armature. Since fixed voltage supply is often used, a variable voltage is obtained by an electronic circuit. When A.C supply is used a Thyristor can be used to control the average voltage applied to armature. PWM – pulse width modulation Control of d.c motors by means of control signal from microprocessors. Brush type motor with nonpermanent magnet Series wound Shunt wound Compound wound Separately excited Series wound Armature and field windings are connected in series. Highest starting torque Greatest no load speed Reversing the polarity of supply will not effect the direction of rotation of rotor. Shunt wound Armature and field coils are in parallel. Lowest starting torque Good speed regulation. Almost constant speed regardless of load. For reversing direction of rotation either armature coil or field coil supply has to be reversed. Compound wound Two field windings one in series an another in parallel with armature windings. High starting torque with good speed regulation. Separately excited Separate control of armature and field coils. Speed of these motors can be controlled by separately varying the armature or field current. Brush less dc motor Its consists of a sequence of stator coils and a permanent magnet rotor. Current carrying conductors are fixed and magnet moves. Rotor is ferrite or permanent magnet. The current to the stator coils are electronically switched by transistor in sequence round the coils. Switching being controlled by position of rotors. Hall effect sensors are used to input signals related to a particular position of rotor. A.C motors Single phase squirrel cage induction motor Its consists of a squirrel cage rotor, this being copper or aluminum bars that fit into slots in end rings to form a complete circuit. Its consists of a stator having set of windings. Alternating current is passed through stator windings an alternating magnetic field is produced. As a result EMF are induced in conductors in the magnetic field. Initially when rotor is stationery net torque is zero. Motor is not self starting. 3-phase induction motor 3 windings located 120 deg apart each winding being connected to one of the three lines of the supply. 3 phase reach maximum currents at different times, magnetic field rotates round the stator poles completing one rotation is one full cycle. Self starting Synchronous motors Similar to that of induction motor but rotor will be a permanent magnet. Magnets rotate with the same frequency as that of rotating magnetic field which rotates 360 deg in one cycle of supply. Used when precise speed is required. Not self starting. Speed control of AC motor Speed control of A.C motor is done by provision of variable frequency supply. Torque is constant when ratio of applied stator voltage to frequency ration is constant. AC is rectified to DC by convertor and inverted back to AC with a selected frequency. Stepper motors Stepper motor is a device that produce rotation though equal angles called as steps, for each digital pulse supplied to its input. Stepper motors Variable reluctance motor Rotor is made of soft steel and is cylindrical with four poles, fewer poles than on the stator. When opposite pair of windings has current switched to them, a magnetic field is produced with line of force pass from stator to nearest poles of rotor. Rotor will until it is in minimum reluctance position. Step angle 7.5 deg to 15 deg. Permanent magnet stepper Two phase four poles. Coils on opposite pairs of poles are in series. Current is supplied from dc source. Rotor is a permanent magnet. Rotor rotates in 45 deg steps. Step angles 1.8, 7.5, 15, 30, 34, or 90 deg available. Hybrid stepper motor Combined features of both variable reluctance and permanent magnet motors. Permanent magnets are encased in iron caps which are cut to have teeth. It motor has n phase and m teeth on the rotor, the total number of steps per revolution will be nm 0.9 and 0.8 deg steps available. High accuracy positioning applications. Specifications Phase Number of independent windings on the stator, eg a three phase motor. Step angle Angle through which the rotor rotates from one switching change for the stator. Holding torque Maximum torque that can applied to a powered motor without moving it from its rest position and causing spindle rotation. Pull – in torque This is the maximum torque against which a motor will start for a given pulse rate and reach synchronism without losing a step. Pull – out torque Maximum torque against that can be applied to a motor, running at a given stepping rate, without loosing synchronism. Pull – in rate Maximum switching rate at which a loaded motor can start without loosing a step. Pull – out rate Switching rate at which a loaded motor will remain in synchronism as the switching rate is reduced. Slew range Range of switching rates between pull-in and pull-out within the motor runs in synchronism but cannot start up or reverse. Bipolar stepper Unipolar stepper H bridge Stepper motor control Two phase motors are termed as bipolar motors when they have 4 connecting wires for signals. Solid state switches can be used to switch dc supply between the pair of stator windings. Bipolar stepper Merits and demerits Merits A high accuracy of motion is possible, even under open-loop control. Large savings in sensor (measurement system) and controller costs are possible when the open-loop mode is used. Because of the incremental nature of command and motion, stepper motors are easily adaptable to digital control applications. No serious stability problems exist, even under open-loop control. Torque capacity and power requirements can be optimized and the response can be controlled by electronic switching. Brushless construction has obvious advantages. Demerits They have low torque capacity (typically less than 2,000 oz-in) compared to DC motors. They have limited speed (limited by torque capacity and by pulse-missing problems due to faulty switching systems and drive circuits). They have high vibration levels due to stepwise motion. Large errors and oscillations can result when a pulse is missed under open-loop control.