Solutions to Review Questions

advertisement

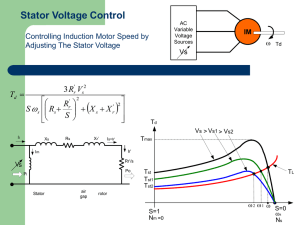

1 Electric Motors and Drives - Third Edition Solutions to Review Questions - Chapter 10 1) The synchronous speed of all a.c. motors (induction, reluctance, synchronous) is governed by 120 f the equation N S . Hence for synchronous speed of 300 rev/min when the supply p frequency is 60 Hz, a winding with 24 poles will be required. 2) In all mains-fed a.c. machines the voltage should be adjusted in proportion to the frequency in order to keep the magnitude of the air-gap flux density wave constant. Hence the voltage at 50 V V 50 350 Volts. Hz is given by 50 60 , i.e. V50 420 50 60 60 3) With no shaft projecting at either end the set-up is clearly not intended to provide any mechanical output power, so we can deduce that one of the machines is intended to run as a motor and drive the other as a generator. The arrangement is in fact a bi-directional frequency changer, for allowing 50 Hz apparatus to be supplied from a 60 Hz system, or vice-versa. The 10-pole machine has a synchronous speed of 600 rev/min at 50 Hz, while the 12-pole machine also has synchronous speed of 600 rev/min when it is supplied at 60 Hz. Both machines can work as motor of generator, so power can be transferred in either direction between the 50 Hz and 60 Hz systems. The machines could be separated and used as synchronous motors. With a 50 Hz supply, the speeds available are 500 and 600 rev/min, while these increase to 600 and 720 rev/min with a 60 Hz supply. 4) The steady-state speed of the rotor is constant because it is locked to the synchronously-rotating field. But when the load torque is increased there is an immediate deceleration of the rotor that causes it to drop back in relation to the rotating field. In so doing the torque produced on the rotor by the field increases, so the deceleration reduces until a new equilibrium position is reached where the speed of the rotor is again exactly synchronous but the torque has increased. A stroboscope illuminating the shaft allows an observer to see the increase in load-angle, which normally occurs rapidly so that the slight and transient departure from synchronous speed is barely perceptible. 5) In a synchronous machine operating in the steady state the magnetic field produced by the stator windings rotates at the same speed as the rotor, so that from the point of view of an observer on the rotor there is no ‘flux cutting’ and therefore no motional e.m.f. The only time that there will be motional e.m.f. in the rotor is during run-up, or when there is a transient load change. This is important in only a limited number of cases, for example under fault conditions in very large synchronous machines connected to the power system. 6) The first thing that we should note is that because there is no mechanical load on the shaft of the motor, the only mechanical power being produced is that associated with any frictional or windage losses, which must be very small. We can deduce that the electrical input power must 2 be small, so the fact that at one value of rotor d.c. excitation the a.c. current in the stator becomes very small should not come as a surprise. To go further we must do as suggested and make use of the equivalent circuit (Figure 10.3) and phasor diagram. We are told that the machine is a large one, so we can make the assumption that the stator resistance is negligible without having much effect on the result. The phasor diagram is shown in Figure 10A. This is based on Figure 10.4, but with the load torque reduced to zero and the losses neglected, in which case the input power becomes zero. The locus of the stator current as the rotor excitation is varied is shown by the dotted line. Fig 10A here Because the power is zero (or at least very small), the real or in-phase component of the stator current is always almost zero: it has been taken as zero in Figure 10A for the sake of simplicity. However, the stator current (I) must be such as to satisfy Kirchoff’s law (that the applied voltage V must equal the sum of the induced e.m.f. E and the volt-drop across the synchronous reactance. Hence we see that when E is small (Fig 10A(a)), the stator current is large and lagging the voltage by 90°, so that the machine looks like an inductance when viewed from the supply. In the extreme case when there is no rotor excitation (E = 0), the stator current has its maximum V value of , and in this condition we see that all of the MMF required to produce the air-gap XS flux is provided by the stator. In this condition the machine has its minimum apparent inductance. (If we were talking about an induction motor with an identical stator to the one here, we would call the current the magnetising current, and we would refer to the stator inductive reactance as the magnetising reactance, rather than the synchronous reactance.) When the rotor excitation (E) is increased the stator current reduces (i.e. the apparent inductance increases) until, when E = V, the stator current is zero. Further increase in E causes the current to increase again, but his time it leads the voltage by 90°, and the machine therefore looks like a capacitor when viewed from the system. Synchronous machines operating in this mode (i.e. without any mechanical power output) were widely used at one time as ‘synchronous compensators’ in power systems. They allow the power-factor of a region to be optimised by being set to have the desired value of inductive or capacitive reactance. 7) During run-up the acceleration is directly proportional to the torque and inversely proportional to the inertia. Hence if the inertia is doubled, the acceleration will be halved and the time taken to reach steady-state speed will increase by a factor of two. In the steady-state there is no acceleration and therefore no torque associated with inertia. Provided that we increase the load torque gradually, so that the accelerating component of torque is negligible, the inertia will have no effect on the load angle at which the maximum torque is developed (i.e. the pull-out condition). 3 EV sin , and so for a given XS supply voltage V and excitation e.m.f. E, the pull-out torque occurs when the load-angle ( ) reaches 90°. As expected, the torque expression does not contain inertia.) (The expression for torque in asynchronous machine is T 8) We can answer this question most directly by making use of the torque expression quoted at EV sin . This expression assumes that the stator resistance has the end of question 7, i.e. T XS negligible influence on the torque, which will be true because we are told that the motor is large. We are asked about what happens when we change the rotor excitation (i.e. E), but, paradoxically we will be better off if we begin by noting what does not change. The main point to note is that the mechanical load torque is unaltered, the steady-state speed remains equal to the synchronous speed, and therefore the torque produced by the motor must remain unchanged. The supply voltage V is naturally unchanged. Hence of we denote the original condition by suffix 1 and the new condition by suffix 2 we can EV E V E 1 sin 40 , 2 25.4. write T 1 sin 1 2 sin 2 , sin 2 1 sin 1 XS XS E 1.5 9) The answer to question 5 makes clear that in the steady-state there are no motional e.m.f.’ s induced in the rotor body or windings, and therefore it is possible for the rotor body to be made of solid steel, rather than laminations. Most large synchronous machines (such as those used as alternators in power plants) must have solid forged rotors in order to achieve the required mechanical strength, but many small ones are made of laminations because it is easier to punch the slots for the winding than to machine them in a solid rotor. 10) Increasing the number of phases makes it easier to achieve the desired sinusoidal spatial distribution of the rotating field, and makes for better utilisation of the conductors, but the down side is that there are more leads and terminals. There is however no fundamental reason, and the current state-of-the-art seems to favour three. 11) There is very little difference form the user’s perspective. The principal internal difference is that the term brushless d.c. tends to be used to describe a motor in which the windings produce a rectangular m.m.f. wave, and the windings are fed with rectangular current waves, whereas a self-synchronous motor will have sinusoidally-distributed windings fed with sinusoidal currents. 12) A unipolar drive circuit is one in which the current can only flow in one direction, for example that shown in chapter 2, Figure 2.4, where the current can only flow downwards through the load. In a reluctance motor, the torque does not depend on the direction of current in the winding, so a simple unipolar supply is satisfactory. 4 A bipolar drive circuit can supply either positive or negative current: for example in Figure 2.13, if transistors 1 and 4 are turned on, the current will flow one way through the load, while if transistors 2 and 3 are turned on instead, the current will flow the opposite way through the load. Clearly the bipolar supply is more complex than the unipolar supply: it requires more switching devices and is therefore more costly. A further advantage of the unipolar circuit is that there is no danger of an inadvertent shortcircuit across the supply, because the winding is always in series with the switching device. In contrast, in a bipolar supply there is a danger that if, by mistake, two switching devices in the same ‘leg’ are turned on simultaneously, a short-circuit will occur and the devices will be destroyed by the excessive current that will flow. 13) The ‘dump’ resistor is provided in drives which cannot continuously convert mechanical energy into electrical energy. The majority of drives seldom require prolonged regeneration, and do not justify the additional expense of a fully-regenerative capability. But most drives need to be able to provide rapid braking (e.g. when the target speed is suddenly lowered), and therefore they are designed so that they can produce negative (braking) torque, and absorb the excess kinetic energy, rather than return it to the mains. The energy is dissipated in a resistor, which therefore gets hot. The resistor will have been designed for operation on an intermittent basis, and continuous operation is unlikely to be permissible, except perhaps at a very low torque. 14) All electromechanical energy converters are inherently capable of operating in motor or generator mode. In practice, the nature of the supply system determines whether bi-directional energy flow is possible. All mains-fed a.c. motors can generate; the cheapest power-electronic converters have no capacity for regeneration; more expensive ones can absorb short-term reverse energy flows, but not return the energy to the supply; and the top of the range models will allow continuous generation. - End of Solutions Chapter 10 -