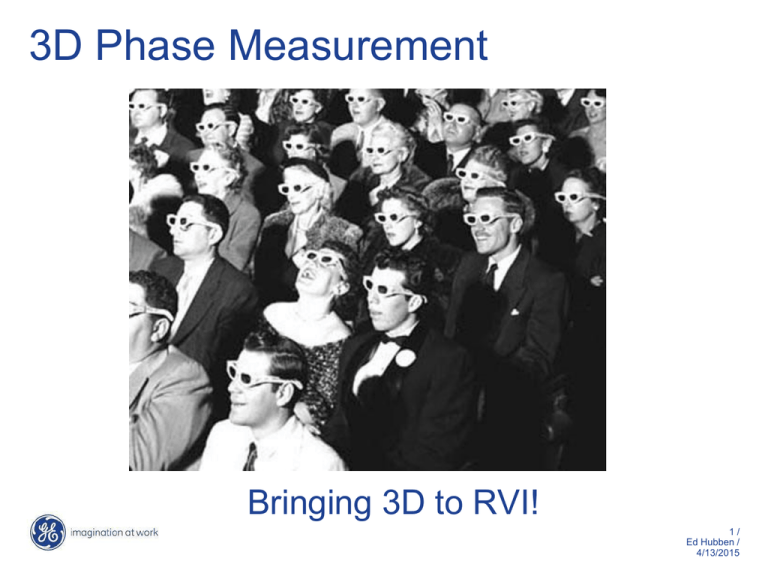

3D Phase Measurement

advertisement

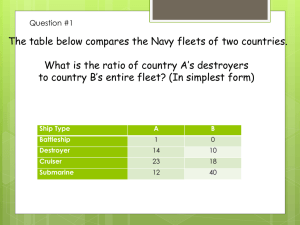

3D Phase Measurement Bringing 3D to RVI! 1/ Ed Hubben / 4/13/2015 3D PM Overview 3D Surface Scanning and Measurement System Video Borescope Technology Enables Internal 3D Examination of Equipment 2/ Ed Hubben / 4/13/2015 Measurement methods Comparison Stereo Shadow 3D Phase 3/ Ed Hubben / 4/13/2015 Comparison Measurement 4/ Ed Hubben / 4/13/2015 Stereo Measurement Technology Split view is difficult to use for general inspection Accuracy and usability are very dependent on surface conditions 5/ Ed Hubben / 4/13/2015 Shadow Measurement Technology Fiber Bundle Slit Aperture Shadow Imager Shadow Tip Close Z1 Far Z2 X and Y should be on a perpendicular plane Only know Z along the shadow line 6/ Ed Hubben / 4/13/2015 Phase Shifting What if we had many shadows? Fiber Bundle Slit Aperture Shadows Imager Shadow Tip Z1 Z2 And the shadows had structure? 7/ Ed Hubben / 4/13/2015 Phase Shifting Typical Setup Image 0 Object Image 1 Image 2 Image 3 Camera Projector 8/ Ed Hubben / 4/13/2015 Phase Shifting in the XLG3 LED Arrays Shadow Pattern Viewing Optics 9/ Ed Hubben / 4/13/2015 Forward View Tip Lens Phase Gratings Arc Lamp Illumination Double Threads Side View Tip Phase Gratings Lens Arc Lamp Illumination Double Threads Optics Configuration • Line patterns are projected using 3 LEDs on each side of viewing optics. • Object distance at each point is computed using pattern trajectories (triangulation) known from calibration. 12 / GE Presenter and Event / 4/13/2015 Phase Images 13 / GE Presenter and Event / 4/13/2015 Phase Images 14 / GE Presenter and Event / 4/13/2015 Phase Images 15 / GE Presenter and Event / 4/13/2015 Image Capture and Analysis 1 2 3 4 16 / Ed Hubben / 4/13/2015 Types of 3D Measurement Length Multi-Segment Length Area Point to Line Depth Depth Profile 17 / Ed Hubben / 4/13/2015 Length and Multi-Segment Length Crack in Turbine Guide Vane 18 / Ed Hubben / 4/13/2015 Area 19 / Ed Hubben / 4/13/2015 3D View of Area 20 / Ed Hubben / 4/13/2015 Point to Line 21 / Ed Hubben / 4/13/2015 Depth 22 / Ed Hubben / 4/13/2015 Depth Map 23 / Ed Hubben / 4/13/2015 Depth – Used for Blade Clearance 24 / Ed Hubben / 4/13/2015 Depth Profile Illustrative example: 25 / Ed Hubben / 4/13/2015 Depth Profile 0.180” Slot Should be in same plane Point furthest from reference plane Scale No Data Distance Between Cursors Cross-Sectional Area (only when no red included) 26 / Ed Hubben / 4/13/2015 Depth Profile Tear in Welded Blade Edge 27 / Ed Hubben / 4/13/2015 Point Cloud 28 / Ed Hubben / 4/13/2015 Point Cloud – x,y,z file Compare worn condition to new geometry 29 / Ed Hubben / 4/13/2015 Application – Turbine Blade 30 / Ed Hubben / 4/13/2015 Application – Weld Inspection 31 / Ed Hubben / 4/13/2015 Weld in 3D Not a flat plate! 32 / Ed Hubben / 4/13/2015

![ShadowPowerp[1]](http://s2.studylib.net/store/data/005442171_1-9acfb2dbdb399f93aedc919e80cb90fa-300x300.png)