Foundations of Materials Science and Engineering Third Edition

advertisement

CHAPTER

7

Mechanical Properties

Of

Metals - II

7-1

Recovery and Recrystallization

•

Cold worked metals

become brittle.

• Reheating, which

increases ductility results

in recovery,

recrystallization and

grain growth.

• This is called annealing

and changes material

properties.

7-2

(Adapted from Z.D. Jastrzebski, “The Nature and Properties of Engineering Materials,” 2d ed., Wiley, 1976, p.228.)

Structure of Cold Worked Metals

•

Strain energy of cold

work is stored as

dislocations.

• Heating to recovery

temperature relieves

internal stresses

(Recovery stage).

• Polygonization

(formation of sub-grain

structure) takes place.

• Dislocations are moved

into lower energy

configuration.

Structure of 85%

Cold worked metal

Polyganization Figure 6.4

Dislocations

Grain Boundaries

Slip bands

Structure of stress

relieved metal

Figure 6.2 and 6.3

7-3

TEM of 85%

Cold worked metal

(After “Metals Handbook,” vol 7, 8th ed., American Society of Metals, 1972, p.243)

TEM of stress

relived metal

Recrystallization

•

If metal is held at recrystallization temperature long

enough, cold worked structure is completely replaced

with recrystallized grain structure.

• Two mechanisms of recrystallization

Expansion of nucleus

Migration of grains.

More deformed

region

Structure and TEM of

Recrystallized metal

Migration

Expansion

Figure 6.5

7-4

Nucleus of

recrystallized grain

(After “Metals Handbook,” vol 7, 8th ed., American Society of Metals, 1972, p.243)

Figure 6.2 and 6.3

Effects on Mechanical Properties

•

Annealing decreases tensile strength, increases

ductility.

• Example:

85% Cu &

15% Zn

Annealed 1 h

4000C

50% cold

rolled

Tensile strength

75 KSI

Ductility 3%

Tensile strength

45 KSI

Ductility 38 %

• Factors affecting recrystalization:

Amount of prior deformation

Temperature and time

Initial grain size

Composition of metal

7-5

Figure 6.6

(After “Metals Handbook,” vol 2, 9th ed., American Society of Metals, 1979, p.320)

Facts About Recrystallization

• A minimum amount of deformation is needed.

• The smaller the deformation, the higher the recrystallization

temperature.

• The Higher the temperature, the less time required.

• The greater the degree of deformation, the smaller the

recrystallized grains.

• The Larger the original grain

size, the greater the amount of

deformation that is required

to produce equivalent

temperature.

• Recrystallization temperature

Figure 6.7b

Continuous annealing

increases with purity of metals.

7-6

(After W.L. Roberts, “Flat Processing of steel,” Marcel Dekker, 1988.)

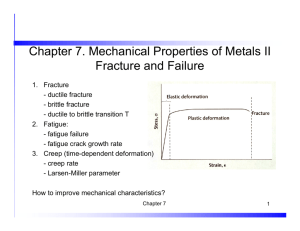

Fracture of Metals – Ductile Fracture

•

•

•

7-7

Fracture results in separation of stressed solid into two

or more parts.

Ductile fracture : High plastic deformation & slow

crack propagation.

Three steps :

Specimen forms neck and

cavities within neck.

Cavities form crack and

crack propagates towards

surface, perpendicular to stress.

Direction of crack changes to

450 resulting in cup-cone

fracture.

Brittle Fracture

•

•

•

No significant plastic deformation before fracture.

Common at high strain rates and low temperature.

Three stages:

Plastic deformation concentrates

dislocation along slip planes.

Microcracks nucleate due to shear

stress where dislocations are blocked.

Crack propagates to fracture.

•

Example: HCP Zinc ingle crystal

under high stress along {0001}

plane undergoes brittle fracture.

Figure 6.11 & 6.13

7-8

SEM of ductile fracture

(From ASM handbook vol 12, page 12 and 14)

SEM of brittle fracture

Ductile and Brittle Fractures

Ductile fracture

Brittle Fracture

Brittle Fractures (cont..)

• Brittle fractures are due to defects like

Folds

Undesirable grain flow

Porosity

Tears and Cracks

Corrosion damage

Embrittlement due to atomic hydrogen

• At low operating temperature, ductile to brittle

transition takes place

Toughness and Impact Testing

•

Toughness is a measure of energy absorbed before

failure.

• Impact test measures the

ability of metal to absorb

impact.

Toughness is measured

using impact testing

machine

Figure 6.14

7-9

Impact testing (Cont…)

•

Also used to find the temperature range for ductile to

brittle transition.

Figure 6.15

•

7-10 (After J.A.Rinebolt and W.H. Harris, Trans. ASM, 43: 1175(1951))

Figure 6.16

Fracture Toughness

• Cracks and flaws cause stress concentration.

K1 Y a

K1 = Stress intensity factor.

σ = Applied stress.

a = edge crack length

Y = geometric constant.

Figure 6.17

KIc = critical value of

stress intensity

factor.(Fracture toughness)

Y f a

7-11

Example:

Al 2024 T851 26.2MPam1/2

4340 alloy steel 60.4MPam1/2

Measuring Fracture Toughness

• A notch is machined in a specimen of sufficient

thickness B.

• B>>a

plain strain condition.

• B = 2.5(KIc/Yield strength)2

• Specimen is tensile tested.

• Higher the KIc value, more

ductile the metal is.

• Used in design to find

allowable flaw size.

Figure 6.18

7-12

Courtesy of White Shell research)

Fatigue of Metals

•

Metals often fail at much lower stress at cyclic loading

compared to static loading.

• Crack nucleates at region of stress concentration and

propagates due to cyclic loading.

• Failure occurs when

cross sectional area

of the metal too small

to withstand applied

Fracture started here

load.

Figure 6.19

Fatigue fractured

surface of keyed

shaft

Final rupture

7-13 (After “Metals Handbook,” vol 9, 8th ed., American Society of Metals, 1974, p.389)

Fatigues Testing

• Alternating compression and tension load is applied on

metal piece tapered towards center.

Figure 6.21

Figure 6.20

• Stress to cause failure S

and number of cycles

required N are plotted

to form SN curve.

Figure 6.23

7-14 (After H.W. Hayden, W.G. Moffatt, and J.Wulff, “The structure and Properties of Materials,” vol. III, Wiley, 1965, p.15.)

Cyclic Stresses

•

Different types of stress cycles are possible (axial,

torsional and flexural).

Figure 6.24

Mean stress = m

max min

2

Stress range = r max min

7-15

Stress amplitude = a

max min

2

min

Stress range = R

max

Structural Changes in Fatigue Process

•

•

Crack initiation first occurs.

Reversed directions of crack initiation caused surface

ridges and groves called slipband extrusion and

intrusion.

• This is stage I and is very slow (10-10 m/cycle).

• Crack growth changes

direction to be perpendicular to maximum tensile

stress (rate microns/sec).

Persistent slip bands

• Sample ruptures by ductile

In copper crystal

failure when remaining

cross-sectional area is small to withstand the stress.

Figure 6.26

7-16

Courtesy of Windy C. Crone, University of Wisconsin

Factors Affecting Fatigue Strength

•

Stress concentration: Fatigue strength is

reduced by stress concentration.

• Surface roughness: Smoother surface

increases the fatigue strength.

• Surface condition: Surface treatments like

carburizing and nitriding increases fatigue

life.

• Environment: Chemically reactive

environment, which might result in

corrosion, decreases fatigue life.

7-17

Fatigue Crack Propagation Rate

•

•

•

Notched specimen used.

Cyclic fatigue action is generated.

Crack length is measured by change in potential

produced by crack opening.

Figure 6.27

7-18(After “Metals Handbook,” Vol 8, 9th ed., American Society of Metals, 1985, p.388.)

Stress & Crack Length

σ2

Fatigue Crack Propagation.

σ1

Δa

ΔN

da

Figure 6.28

dN

Δa

ΔN da

da

dN

1

α f(σ,a)

AK

m

dN

2

• When ‘a’ is small, da/dN

is also small.

• da/dN increases with increasing crack length.

• Increase in σ increases

crack growth rate.

da

= fatigue crack growth

rate.

dN

ΔK = Kmax-Kmin = stress

intensity factor range.

A,m = Constants depending on material, environment, frequency

temperature and stress ratio.

7-19

Fatigue Crack Growth rate Versus ΔK

da

Log( AK m )

Log

dN

m. Log( K ) Log( A)

Straight line with slope m

Limiting value of ΔK below

Which there is no measurable

Crack growth is called stress

intensity factor range

threshold ΔKth

Figure 6.29

7-20

(After P.C. Paris et al. Stress analysis and growth of cracks, STP 513 ASTM, Philadelphia, 1972, PP. 141-176

Fatigue Life Calculation

da

AK m

dN

K Y a

But

m

m

Therefore K m y m m 2 a 2

da

Therefore

m

m

A( y m m 2 a 2 )

dN

Integrating from initial crack size a0 to final crack size af

at number of fatigue cycles Nf

af

m

m Nf

m m

2

2

da

A

y

a

dN

a0

0

Integrating and solving for Nf

(Assuming Y is independent of crack length)

7-21

Nf

af

(

m

2

) 1

a0

m

m

Ay (

m

m

m

(

2

2

2

) 1

1)

Creep in Metals

•

•

•

•

•

•

Creep is progressive deformation under constant

stress.

Important in high temperature applications.

Primary creep: creep rate

decreases with time due

to strain hardening.

Secondary creep: Creep

rate is constant due to

simultaneous strain hardening and recovery process.

Tertiary creep: Creep rate

increases with time leading

to necking and fracture.

Figure 6.30

7-22

Creep Test

•

Creep test determines the effect of temperature and

stress on creep rate.

• Metals are tested at constant stress at different

temperature & constant temperature with different

stress.

High temperature

or stress

Medium temperature

Figure 6.33

or stress

Creep strength: Stress to produce

Low temperature

Minimum creep rate of 10-5%/h

or stress

Figure 6.32

7-23

At a given temperature.

Creep Test (Cont..)

•

Creep rupture test is same as creep test but aimed at

failing the specimen.

• Plotted as log stress

versus log rupture time.

• Time for stress rupture

decreases with increased

stress and temperature.

Figure 6.35

Figure 6.34

7-24

(After H.E. McGannon [ed]. “ The making, shaping and Treating of Steel,” 9 th ed., United States Steel, 1971, p. 1256

Larsen Miller Parameter

•

Larsen Miller parameter is used to represent creepstress rupture data.

P(Larsen-Miller) = T[log tr + C]

T = temperature(K), tr = stress-rupture time h

C = Constant (order of 20)

Also,

or

P(Larsen-Miller) = [T(0C) + 273(20+log tr)

P(Larsen-Miller) = [T(0F) + 460(20+log tr)

• At a given stress level, the log time to stress rupture

plus constant multiplied by temperature remains

constant for a given material.

7-25

Larsen Miller Parameter

If two variables of time to

rupture, temperature and

stress are known, 3rd parameter

that fits L.M. parameter can be

determined.

Example:

For alloy CM, at 207 MPa,

LM parameter is 27.8 x 103 K

Then if temperature is known,

time to rupture can be found.

Figure 6.36

7-26

(After “Metals Handbook,” vol 1, 10th ed., ASM International, 1990, p.998.)

L.M. Diagram of several alloys

Figure 6.37

Example: Calculate time to cause 0.2% creep strain in gamma

Titanium aluminide at 40 KSI and 12000F

From fig, p = 38000

38000 = (1200 + 460) (log t0.2% + 20)

7-27After N.R. Osborne et. al., SAMPE Quart, (4)22;26(1992)

t=776 h

Case Study – Analysis of Failed Fan Shaft

• Requirements

Function – Fan drive support

Material 1045 cold drawn steel

Yield strength – 586 Mpa

Expected life – 6440 km (failed at 3600 km)

• Visual examination (avoid additional damage)

Failure initiated at two points near fillet

Characteristic of reverse bending fracture

Failed Shaft – Further Analysis

• Tensile test proved yield strength to be 369

MPa (lower than specified 586 MPa).

• Metallographic examination revealed grain

structure to be equiaxed ( cold drawn metal has

elongated grains).

• Conclusion: Material is not cold drawn – it is

hot rolled !.

Lower fatigue strength and stress raiser

caused the failure of the shaft.

Recent Advances: Strength + Ductility

•

•

Coarse grained – low strength, high ductility

Nanocrystalline – High strength, low ductility (because

of failure due to shear bands).

• Ductile nanocrystalline copper : Can be produced by

Cold rolling at liquid nitrogen temperature

Additional cooling after each pass

Controlled annealing

•

•

Cold rolling creates dislocations

and cooling stops recovery

25 % microcrystalline grains

in a matrix of nanograins.

Fatigue Behavior of Nanomaterials

• Nanomaterials and Ultrafine Ni are found

to have higher endurance limit than

microcrystalline Ni.

• Fatigue crack growth is increased in the

intermediate regime with decreasing grain

size.

• Lower fatigue crack growth threshold Kth

observed for nanocrystalline metal.