Fatigue and Creep crack growth in Asphalt Materials

advertisement

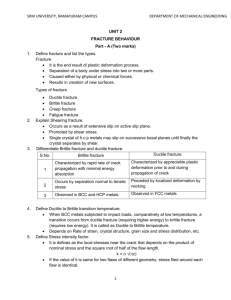

Fatigue and Creep crack growth in Asphalt Materials Jan Zuidema1, Ad Pronk2 and Fedde Tolman3 Laboratory for Materials Science, Delft University of Technology, R’damseweg 137, 2628 AL, Delft, The Netherlands 2 Ministry of Transport and Public Works / Road and Hydraulic Engineering Division, P.O. Box 5044, 2600 GA Delft, The Netherlands 3 Netherlands Pavement Consultants, P.O. Box 2756, 3500 GT Utrecht, The Netherlands Traffic loading is one of the main causes of deterioration of asphalt concrete pavements. Asphalt mixtures, consist of a graded mineral aggregate bound by bitumen and are therefore inhomogeneous visco-elastic materials, in which defects are always present. When the stresses are high enough, defects act as crack initiators. Both cyclic loading and constant (non-cyclic) loading may result in crack initiation and growth. In this work we compare the crack growth which occurs in practice due to long-term repetitive traffic loading (i.e. fatigue) with crack growth due to constant loading (i.e. creep) for two different asphalt materials. 100 K = 0.33 MPam, R = 0.1, f = 10 Hz a (mm) 80 60 40 20 0 200000 400000 600000 800000 N (cycles) Figure 1. crack length versus number of cycles in a constant K test. We will describe crack growth using the stress intensity factor K, being a geometry independent unifying parameter. It is assumed that the stress field near the crack tip may be described by this linear elastic fracture mechanics parameter K, the stress intensity factor, only under certain circumstances of temperature and frequency. Use of this factor yielded in previous investigations reasonable results, although it is realized that the material in study is not linear elastic. In these previous investigations fatigue tests were performed at positive and negative values of the load ratio R (i.e. tensile and compression stresses). The results will be compared with results from constant load experiments, where the crack growth mechanism is creep, i.e. slow stable crack growth. The fatigue tests were also performed at different frequencies. With a simple calculation it is possible to distinguish for the relative contributions of fatigue and creep mechanisms on crack growth and for predicting the shift in the fatigue crack growth per cycle, da/dN, for different frequencies. It was shown (1,2) that for positive values of the load ratio R (i.e. only tensile stresses), it was possible to fit the results for different frequencies into one scatter band, when the frequency f times the crack growth rate per cycle, da/dN, was plotted against K. The crack growth mechanism is creep then, as in this case the effect of R on the results of the fatigue tests can be predicted from the results of slow stable crack growth (creep) under constant loading. However, for negative R-values (i.e. with also compressive stresses) this was found to be not possible. Fatigue becomes an important crack growth mechanism in such cases. In order to investigate the fatigue and creep crack EXPERIMENTS Crack growth tests were performed on center-cracked tensile specimens 390 mm long, 230 mm wide and 30 mm thick (2 mm stone) or 40 mm (8 mm stone) under fatigue and creep loading conditions. The first material was sand asphalt with a maximum aggregate size of 2 mm (Dutch code dab 0/2). The asphalt mix contained 8.5-wt % bitumen 45/60; the mineral aggregate consisted of 20% Wigro filler, 75% crushed sand and 5% river sand. The other material was dense asphalt concrete with a maximum aggregate size of 8 mm (Dutch code dab 0/8). This asphalt mix contained 7% bitumen 80/100; the mineral aggregate consisted of 31.3% 4/8 stones, 22.4% 2/6 stones, 6.8% V40K filler, 29.6% crushed sand and 9.9% river sand. The test temperature for all tests was 0 ºC. Fatigue and creep crack growth tests were performed. Various frequencies and R values were used for the fatigue crack growth tests. Fatigue tests were performed either with constant load amplitude or with constant K. In both cases this was achieved by controlling the (sinusoidal) load. The crack length was found by digital image processing. The procedure is described in detail by Riemslag (3). THEORY The linear elastic K factor for the specimens is: P a K a sec( ) (1) t w w The accuracy is < 1% for 2a/w 0.8. In Figure 1 the measured crack length versus the number of cycles is shown for a constant K test. The linear result in this figure is the basis for the use of K as a crack growth controlling parameter, i.e. the crack growth rate da/dN is independent of the crack length. If the crack growth under constant amplitude fatigue loading conditions is due to a pure creep mechanism, then the crack growth rate da/dt = f da/dN is not fre- quency-dependent. If we compare two situations with different fatigue loading frequencies f1 and f2 we obtain in a pure creep case f1·(da/dN)f1= f2·(da/dN)f2 (2) where (da/dN)f is the increase in crack length per cycle for frequency f. However, if we have a pure fatigue crack growth mechanism, there is no frequency dependence of da/dN. In this case: (da/dN)f = (da/dN)f (3) 1 2 Thus when we perform tests at different frequencies, we will obtain overlapping results in the case of a pure creep crack growth mechanism when we plot f da/dN versus K. This was found in (1) for fine sand asphalt for all positive R values, but not for negative R - values. It was concluded that for positive Rvalues the growth mechanism is pure creep and for negative R-values it is a mix of fatigue and creep mechanisms. We now assume that a simple superposition of both 1000 100 da/dt ( m/sec) growth rate behavior in asphalt mixes further, a new series of experiments was conducted on centercracked tensile specimens. 10 P = 5 kN (dab 0/8) 1 P = 5 kN (dab 0/8) da/dt = 878 K^3.65 dab 0/8 P = 4 kN P = 4.8 kN 0.1 da/dt = 330 K ^4 0.1 1 K (MPam) Figure 2. Creep crack growth tests of both materials. fatigue and creep parts is permitted. The pure fatigue part of da/dN can be found by meas- uring the real da/dN and calculating da/dN for pure creep, using a creep crack growth relation. Subtraction then delivers the pure fatigue part. spread the trendlines for 1 Hz and 10 Hz are separated by a factor of about 10. The result at 29.3 Hz does not fit so well compared with the other two. RESULTS In figure 2 creep crack growth results are shown. The crack growth rate da/dt is plotted against K. Tests were performed under constant load conditions. Very much spread in results is found for the coarse dab 0/8. A possible cause may be the material inhomogeneity. Trend lines are plotted trough the results. Type of “Paris relations” can be found for the da/dt versus K, see figure 2. da/dN (m/cycle) 100 10 1 1 Hz 10 Hz 29.3 Hz fit for 1 Hz fit for 10 Hz fit for 29.3 Hz 0.1 100 crack length (mm) 90 0.01 80 0.1 1 K (MPam) 70 60 50 Figure 4. crack growth rate versus K for three frequencies for dab 0/8. 40 30 20 f=29.3 Hz, R=0.18, DeltaP=7.9 kN 10 f=10 Hz, R=0.1, DeltaP=7 kN f=1 Hz, R=0.1, DeltaP=7 kN 0 0 100000 200000 N (cycles) 300000 Figure 3. crack length versus number of cycles for three frequencies for dab 0/8. In Figure 3 results are shown of crack length versus number of cycles for dab 0/8. The crack growth started at about 24 mm for the three tests. The mechanical parameters are almost identical except for the frequency. It can be seen that about 10 times more cycles are needed for crack growth until 50 mm for the test at 10 Hz compared with the test at 1 Hz. This points to a creep mechanism of crack growth. This fact is also visible in Figure 4 where the crack growth rate da/dN is plotted against K. Despite the large In Figure 5 the effect of R is shown for da/dN versus K plots for material dab 0/8. The trendlines and the corresponding formulae are also shown. The fat lines through the data points are predictions based on a calculation of da/dN – K using the creep data of Figure 2. These creep equations form the basis for the prediction of da/dN (or f da/dN) versus K, when a pure creep crack growth mechanism is present. For calculation of the creep part of da/dN the sinusoidally varying K fatigue loading signal is divided into 100 steps per cycle. For each step the crack growth increase is calculated using the creep equations. The result of the calculation matches the measurements quite reasonable for these R-values of 0.5 and 0.1. In Figure 6 a plot is shown for dab 0/2. Besides R=0.5, also a negative R=-1 is used for these results. The same calculation of da/dN is also performed here. The result of the calculation matches very good for R=0.5, but not for R=-1. In the latter case a calculation based only on creep equations is obviously not allowed when also compression stresses are involved. 10 da/dN (m/cycle) predictions ing the da/dN at a different frequency. We have found that f da/dN (and da/dN ) at K = 0.7 MPam is 1/3 due to creep and 2/3 due to fatigue (for R = -1 and f = 29.3 Hz). 100.0 1 R = 0.1 y = 478.12x4.0731 0.1 R = 0.5 0.01 0.01 y = 27.372x4.6731 R2 = 0.7734 0.1 1 fda/dN (µm/sec) R2 = 0.8367 10.0 R = 0.5 R = -1 1.0 R = 0.5 R = -1 K (MPam) Figure 5. R-effects and predictions for dab 0/8. Note that in Figure 6 f da/dN is plotted versus K in stead of da/dN as in Figure 5. A very good result is obtained for a positive R = 0.5 value with only tensile stresses For the negative R = -1 value the prediction does not fit the actual results.It is assumed that a fatigue contribution to da/dN is present in this situation We can use the measurement results to find the pure fatigue contribution. The real f da/dN at K = 0.7 MPam and R = -1 is assumed to consist of a superposition of pure creep and pure fatigue parts. The real f da/dN value = 3 m/s. The creep part = 1 m/s, as calculated. This leads to a pure fatigue f da/dN of 2 m/s. PREDICTION OF da/dN AT A DIFFERENT FREQUENCY The foregoing result offers the possibility of predict- pure creep prediction Power (R = 1) 0.1 0.1 1.0 K (MPam) 10.0 Figure 6. R-effects and predictions for dab 0/2. We can now predict da/dN at f = 2.93 Hz . When the frequency is lowered by a factor of 10, from 29.3 to 2.93 Hz, only the pure creep part of the real da/dN ( 1/3 of the total value) will be affected. This part will increase by a factor of 10, see equation 2. The fatigue part will be unaffected by a frequency change. This leads to: (da/dN) 2.93 = 10 1/3 (da/dN) 29.3 + 2/3 (da/dN) 29.3 = 4 (da/dN) 29.3 (4) A change in frequency by a factor of 10 will thus lead to a change in crack growth rate by a factor 4 for R=-1, see Figure 7. CONCLUSIONS The asphalt material dab 0/8 shows a much larger crack growth rate than the material dab 0/2. Predictions of da/dN, based on creep crack growth data, seems justified for positive values of R, thus for tensile stresses. For negative R-values the prediction doesn’t work so well. It is assumed that fatigue plays a role under these circumstances. We conclude that it seems justified to divide the crack growth rate at negative R-values into pure fatigue and creep parts. The total crack growth rate da/dN can be found by simple addition of the pure fatigue and creep crack growth rate parts. da/dN (m/cycle) 10 1 2.93 Hz 0.1 29.3 Hz R = -1 and P = 10 kN 0.01 0.1 1 K (MPam) Figure 7. results of identical tests (except for the frequency) for dab 0/2 SYMBOLS USED a f K N P deltaP R t w = length of a single crack (in mm) = frequency = stress intensity factor (MPam) = number of cycles = load (in kN) = Pmax - Pmin = load ratio = Pmin/Pmax = Kmin/Kmax = specimen thickness = specimen width REFERENCES 10 1) Kleemans, C.P., Zuidema, J., Krans, R.L., Molenaar, J.M.M. and Tolman, F., Fatigue and Creep Crack Growth in Fine Sand Asphalt Materials, Journal of Testing and Evaluation, Vol. 25, No. 4, July 1997, pp. 424-428. 2) Jan Zuidema, Johan Schulte, Rutger L. Krans and Fedde Tolman, Creep-Fatigue Interactions during Crack Growth in a Fine-Sand Asphalt Concrete Mixture, ECF12 Fracture From Defects, pp 15331538, Vol III, september 1998, Sheffield 3) Riemslag A.C., Crack growth in polyethylene, Delft University Press, ISBN 90-407-1453-3, Delft, 1997.