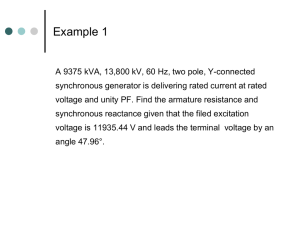

equipment in power distribution

advertisement

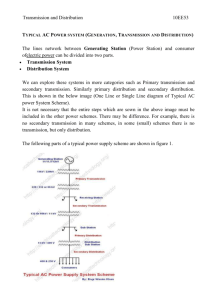

POWER DISTRIBUTION & POWER LOSS REDUCTION METHODS www.Fullinterview.com CONTENTS Power Distribution System Equipment in Power Distribution Losses in the System Methods of Reducing Losses POWER DISTRIBUTION Classification of Power Distribution 1. According to type of current a. DC Distribution b. AC Distribution 2. According to construction a. Over head distribution system b. Underground distribution system 3. According to service a. General lighting and power b. Industrial power c. Street Lighting 4. According to number of wires a. Two wire b. Three wire c. Four wire 5. According to scheme of connections a. Radial system b. Ring system c. Inter connected system CONNECTION SCHEMES OF DISTRIBUTION SYSTEM Radial system: In this system feeders radiate from single sub station and feed the distribution at one end only. Ring system: In this system each consumer is supplied via two feeders. The arrangement is similar to two feeders in parallel on different routes. Inter connected system: In this system the feeder ring is energized by two or more generating stations or sub stations. POWER DISTRIBUTION AT NFC 132kV MAIN RECEIVING STATION 132kV is step down to 33kV or 11kV over two 3 windings transformer of capacity 20/31.5MVA 132kV/33kV/11kV. The two feeders at 132kV are of 100% capacity An ON LOAD TAP CHANGER (OLTC) which is controlled by automatic voltage regulator to provide a constant secondary voltage of 11kV irrespective of primary incoming feeder voltage in a range of 33kV DISTRIBUTION SYSTEM 33kV is step down to 6.6kV by two 15/20MVA, 33kV/6.6kV transformer. The step down secondary voltage is connected to the switch board through a closed type bus duct 6.6kV switch board as 20 bulk oil circuit breaker to feed the 1250kVA, 6.6kV/433V transformer. 11kV DISTRIBUTION SYSTEM 11kV supply from 20/31.5MVA transformer is drawn to the switch panel through XLPE cables. SF6 gas circuit breaker CAPTIVE POWER GENERATION PLANT (CPGP) Maximum demand of NFC made with APTRANSCO is 10MVA. Total capacity of 7.5MVA, consisting of 3 DG sets, each of 2.5MVA capacity. DG sets are connected to an 11kV bus of the power plant which is linked with the 11kV with board of MSDS-1 over to full capacity feeders. Every production unit is provided with a diesel generator set of capacity 40kVA or 180kVA or 500kVA according to their emergency demand. EQUIPMENT IN POWER DISTRIBUTION Bus bars: Bus bars or buses are conductors to which several local feeders or sources are connected. 1. Outdoor Bus bars 2. Indoor Bus bar 3. Compound Immersed Bus bar Various types of bus bar arrangements: 1. Single Bus bar Arrangement 2. Duplicate Bus bar Arrangement 3. Sectionalization of Bus bar 4. Ring Bus Circuit breakers: Circuit breaker requires the separation of contacts in a presence of a dielectric medium which serves two functions as 1. It extinguishes arc between two contacts. 2. Provides adequate insulation between the contacts and from each contact to earth. Classification of Circuit Breaker: 1. Air Circuit Breakers 2. Oil Circuit Breakers 3. SF6 Circuit Breakers Surge Arresters: Surge arresters are used to protect the apparatus insulation from lightning surges and switching surges. Surge arresters are usually connected between phase and ground in distribution system; near the terminals of the large medium voltage machines and in HV, EHV, HVDC substations. Two types of Surge Arresters: 1. Gapping Silicon Carbide Surge Arresters 2. Zinc Oxide Gapless Arresters. EQUIPMENT IN POWER DISTRIBUTION S.No Equipment Functions 1 Bus bars Incoming and outgoing circuits are connected to bus bars 2. Lightening arrestors To discharge lightning over voltages and switching over voltages to earth 3. Shunt reactor in E.H.V substations Series reactors 4. 5. 6. To provide reactive power compensation during low loads. To reduce the short circuit currents or starting currents. Neutral Grounding Resistor To limit the earth fault currents. Coupling Capacitor To provide connection between high voltage line and line carrier currents equipment. S.No Equipment Functions 7. Line Trap 8. Shunt Capacitors 9. Power Transformers To prevent high frequency signal from entering other zones To provide compensations to reactive loads of lagging power factors. To step-up or step-down the voltage and transfer power from one A.C voltage to other A.C voltage at same frequency. 10. Series Capacitors Compensation of series reactors of long lines. LOSSES IN THE POWER DISTRIBUTION Distribution Line Losses Transformer Losses: 1. Core Losses 2. Copper Losses 3. Dielectric Losses 4. Stray Magnetic Losses: Losses due to Harmonics Losses due to low power factor Miscellaneous losses IMPROVEMENTS IN POWER DISTRIBUTION IN AN INDUSTRY Energy Management System Power Factor Correction High Efficiency Transformers 1. Dry Type Transformer 2. Amorphous Core Type Transformer Lighting Energy Management System Industrial Energy Management systems are key factors in energy cost conservation. Monitoring and reports Load shedding Load forecasting Monitoring and Report Monitoring and reports also reveal at what times there were particularly high loads. From here strategies can be developed to avoid such critical situations. Load Shedding Load shedding modules in an energy management system offer the possibility of specifying a "turn-off strategy" which states precisely which consumers may be turned off at all and in which order. Industrial load forecasting: Load forecasting gives you a preview of your company’s load curve, it stores knowledge about the production processes’ behavior in typical production situations from several hours to several days ahead. Forecasting can be done in three modes: 1. Assistance Mode 2. Semi-automatic Mode 3. Automatic Mode DRY TYPE TRANSFORMERS Rating ranges from 100 to 20000 KVA They make use of flame-retardant inorganic insulating materials which free these transformers from all restrictions that apply to oil-filled electrical equipment, such as oil-collecting pits, fire walls, fire extinguishing equipment, etc. Dry Type Transformers are installed wherever oilfilled units cannot be used Their efficiency is rated at 99.02% DRY-TYPE TRANSFORMERS 1,500 kVA Standard (Aluminum) Load Factor** High-Efficiency (Copper) Standard (Aluminum) 65% High-Efficiency (Copper) 85% Efficiency 98.64% 99.02% 98.47% 99.02% Temp. Rise (100% load) 150° C 80° C 150° C 80° C Core Loss 4.3 kW 5.5 kW 4.3 kW 5.5 kW Conductor Loss 9.1 kW 4.1 kW 15.5 kW 7.1 kW Total Loss 13.4 kW 9.6 kW 19.8 kW 12.6 kW – 3.8 kW – 7.2 kW First Cost Rs.7lacs Rs.9lacs Rs.7lacs Rs.9lacs Cost Premium – Rs.2lacs – Rs.2lacs Power Saving Benefits of Using High-Efficiency Copper-Wound Dry-Type Transformers Electrical Energy Cost Annual Savings Payback Period Annual Savings Payback Period Rs.2.25/kWh Rs.57000 3.5 y Rs.1.05lacs 1.9 y Rs.3.15/kWh Rs.80000 2.5 y Rs.1.53lacs 1.3 y Rs.4.05/kWh Rs.1lacs 2.0 y Rs.2.1lacs 1.0 y AMORPHOUS TRANSFORMERS Amorphous Transformer has become well known after "Super amorphous transformer" produced by Hitachi Ltd., Amorphous transformer uses amorphous alloy in the core. Core material is an alloy of Fe,B,Si. Low iron loss, High permeability, Low stress sensitivity Comparison between important transformer characteristics of amorphous material and grain oriented electrical steel. Performance of 315kVA and 630kVA 3 phase, demonstration transformers with wound amorphous cores. POWER FACTOR CORRECTION The input power factor is the real power divided by the apparent power BENEFITS 1. Released System Capacity 2. Reduced Power Losses 3. Voltage Improvement