Document

TYPICAL ELEMENTS

Triangular shell element

6 D.O.F. per node

Tetrahedral solid element

3 D.O.F. per node

First order elements

Linear displacement distribution

Constant stress distribution

Second order elements

Second order displacement distribution

Linear stress distribution

1

TWO POSSIBLE REPRESENTATIONS OF A PLATE

2

CAN YOU IDENTIFY THESE ELEMENTS?

Note: all these elements would be way too large for analysis

3

SW TERMINOLOGY

Draft Quality – first order element

High Quality – second order element

4

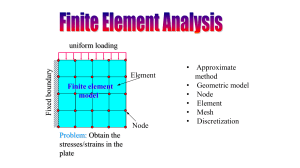

FINITE ELEMENT MESH

Mesh compatibility

Mesh quality

Mesh adequacy

5

MESH COMPATIBILITY

Compatible elements

The same displacement shape function along edge 1 and edge 2

Incompatible elements

The same displacement shape function along edge 1 and edge 2

6

MESH COMPATIBILITY

Model of flat bar under tension. There is an incompatibility along the mid-line between the left and the right side of the model.

The same model after analysis. Due to incompatibility a gap has formed along the mid-line.

7

MESH COMPATIBILITY

Tetrahedral solid elements

Hexahedral solid elements

Tetrahedral solid elements and hexahedral solid elements combined in one model.

8

Solid elements

MESH COMPATIBILITY

Shell elements

Shell elements and solid elements combined in one model.

Shell elements are attached to solid elements by links constraining their translational D.O.F. to D.O.F. of solid elements and suppressing their rotational D.O.F. This way nodal rotations of shells are eliminated and nodal translations have to follow nodal translations of solids.

Unintentional hinge will form along connection to solids if rotational D.O.F. of shells are not suppressed.

Exaggerated stress concentration may appear along the link lines.

9

MESH QUALITY

Elements before mapping Elements after mapping

10

MESH QUALITY aspect ratio angular distortion ( skew ) angular distortion ( taper ) curvature distortion midsize node position warpage

11

MESH QUALITY

Element distortion: aspect ratio

Element distortion: warping

12

MESH QUALITY

Element distortion: tangent edges

13

MESH ADEQUACY

This stress distribution need to be modeled

This is what is modeled with one layer of first order elements

14

MESH ADEQUACY cantilever beam, model 1 terribly bad cantilever beam, model 2 also terribly bad cantilever beam model 3 a good beginning !

cantilever beam, model 4 an acceptable model cantilever beam size: modulus of elasticity: load: beam theory maximal deflection: beam theory maximal stress:

10" x 1" x 0.1"

30,000,000 PSI

150 lb.

f = 0.2"

= 90,000 PSI our definition of the discretization error :

( beam theory result - FEA result ) / beam theory result model #

1

2

3

4

FEA deflection

[in]

0.1358

0.1791

0.1950

0.1996 deflection error

[%]

32

10

2.5

0.2

FEA stress

[ PSI ]

1,500

39,713

65,275

80,687 stress error

[%]

98

56

27

10

15

MESH ADEQUACY

Two layers of second order solid elements are generally recommended for modeling bending.

Shell elements adequately model bending.

16

MESH ADEQUACY

Incorrect shell elements meshing using automatically generated mid-surface

17