Transmission Line Mechanical Design: Sag & Tension

advertisement

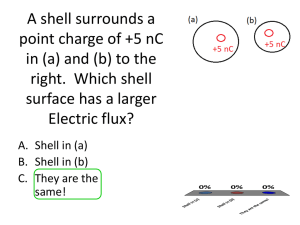

Mechanical Design of Transmission Lines Farhan Mahmood EED, UET Lahore. 1 Main Considerations in the Mechanical Design The main considerations in the mechanical design of an overhead transmission line are: Adequate clearance between conductor and ground High mechanical strength of the conductors Tension or working stress of the conductor < ultimate tensile strength Ultimate tensile strength = F.O.S Χ working stress 2 Basic Design Considerations While erecting an overhead line, it is important that conductors are under safe tension. If the conductors are too much stretched between supports to save the conductor material, the stress in the conductor may reach unsafe value and in certain cases, the conductor may break due to excessive tension. In order to permit safe tension in the conductors, they are not fully stretched but are allowed to have a dip. 3 Few Important Terms in the Mechanical Design TENSION, a force tending to stretch or elongate a conductor. ULTIMATE TENSILE STRENGTH, maximum stress, which a conductor can withstand without failure. 4 Few Important Terms in the Mechanical Design SAG, the vertical distance (d) between the mid-point of a conductor to the line joining the two supports level. 5 Few Important Terms in the Mechanical Design CATENARY‘S CURVE, When the conductor is suspended between two supports at the same level, it takes the shape of catenary's curve. However, if the sag is very small as compared with the span, then sag-span curve is parabola. 6 Few Important Terms in the Mechanical Design SPAN, the horizontal distance (L) between the two adjacent supports. 7 Points to Remember The following points are to be noted, The tension at any point on the conductor is tangent to that point The horizontal component of the tension is constant throughout the length of wire. The tension will be maximum at the supports and minimum at the lowest point of the curve. 8 Factors affecting Sag SAG plays a very important role in the mechanical design of an overhead line. It is not a good practice to provide either too high or too low sag. Sag (Too Low) Sag (Too High) 1. Tension in the conductor is too high 1. Tension in the conductor is too low 2. Less conductor length is required 2. More conductor length is required 3. Lower supports are required 3. Higher supports are required It is always desired that tension and sag should be as low as possible, which is not possible simultaneously. Low Sag ------> tight wire & high tension High Sag ------> loose wire and low tension Therefore, a COMPROMISE is made between the two. 9 Factors affecting Sag The factors affecting the sag of a conductor strung between supports are Weight of conductor Distance between the length) Working tensile strength Temperature supports (span 10 Sag Calculations A conductor AOB of length l’ is suspended at two towers A and B and are A spaced L unit apart. Let O is the lowest point of the wire. Consider a length OP of the curve length s. w = weight/unit length, H = tension at point O T = tension at point P, H x 11 Sag Calculations Three forces are acting on it Horizontal tension H at the lowest point Weight ws of OP acting through its center of gravity Tension T at point P along tangent to the curve at P. For equilibrium, horizontal forces in one direction must be balanced by horizontal forces in the other direction. Same is true for vertical forces. 12 Sag Calculations Let θ be the angle which the tangent at P makes with the horizontal. T sin θ T cos θ ws 13 Components of Tension ………(1) …….(2) Dividing equation 1 by 2 we get …….(3) 14 Length …..(4) 15 Length From equation 3 we have So eq. 4 becomes 16 Length Integrating both sides , we have Where A is the integration constant 17 Length Using intial values as x=0 s=0 we get A = 0, So we have, 18 Length …….(5) 19 Calculation of Sag As we know that So, Since 20 Calculation of Sag or Integrating both sides we have 21 Sag Calculations Where B is the Integration constant Using initial values x=0 y=0 We get B = -H/w So, 22 Sag Calculations This equation is called the equation of catenary On Expanding we get 23 Calculation of Tension Neglecting high powered terms we get The tension at point P is, 24 Calculation of Tension When x=L/2 , y is equal to the sag or deflection ‘d’ 25 Calculation of Length Using the equations, After putting the value of H from expression of d into l, 26 Solve Example The weight of a overhead conductor of a line is 4.0 N/m. The ultimate strength is 8000 N. If safety factor is 4 and span length is 160 m, find (a) sag and (b) total length of the line between spans. 27 Solution 28 Continued… 29 Supports at different levels (unsymmetrical span) 30 Continued… Let P1 and P2 are two points at heights h1 and h2 from the ground respectively, where h is difference between the elevations of two supports. If the span length is L, x1 + x2 = L. Therefore, 31 Continued… 32 Continued… 33 Solve Example An overhead transmission line conductor has the following data Weight = 0.35 kg/m; Maximum allowable strength = 800 kg; Safety factor = 2; Span length = 160 m. Supports are at different levels where one support is at 70 m from the ground. Find the minimum clearance from the ground and the minimum point of the catenary from the supports when the second support is at (a) 40 m and (b) 65 m. 34 Solution 35 Continued… This shows that the minimum point lies outside of the span is 134.29 m from the lower span. Therefore, the minimum ground clearance is 40 m that is the height of lower support. 36 Continued… 37 EFFECT OF ICE- AND WINDLOADING 1. 2. 3. The sag and tension of lines are different in normal weather conditions. Since lines are designed for all the conditions, it is important to calculate the sag and tension during the ice- and wind-loading conditions. Conductor weight Ice Loading Wind Loading 38 Conductor Weight The weight of the conductor acts vertically downwards and depends upon the type of the conductor used. The weight of the conductor per unit length is available from the table giving the mechanical characteristics of the conductor. 39 Ice Loading In snowy areas, ice is deposited on the conductors and its accumulation on the conductor affects the design of line, By increasing the weight per unit length. By increasing the projected surface area subjected to wind pressure In calculations, it will be assumed that ice is uniformly on the surface of the conductor. 40 Ice Loading Cross-section area of conductor = π d2 / 4 Cross-section area of ice coated conductor = π (d + 2t)2 / 4 Cross-section area of ice 41 Ice Loading If density of ice = ρi Weight of ice Wi = Ai х ρi Total weight of conductor per unit length WT = W + Wi 42 Combined effect of wind & ice Projected area of the conductor = (D+ 2t) x 1 ww = (D + 2t)ρ kg/m Where ρ is the wind pressure per unit area acting in a direction normal to the direction of span 43 Effective Loading 44 Assignment An ACSR conductor has the following data: normal copper area = 120 mm2 size = (30 + 7)16.30 mm; weight = 0.4 kg/rn, tensile strength = 1250 kg, safety factor = 5. If span length is 200 m, find Sag in still air Sag, if the conductor is covered with 0.5-cm thick ice (ice density of 915 kg/rn3) Sag (total and vertical), if the conductor is covered with ice of 0.5-cm thickness and a wind pressure of 10 kg/rn2 is acting on the projected area. 45 Solution… 46 Continued… 47 Continued… 48 Continued… 49 50