Sag Effect on Transmission Lines: Analysis & Solutions

advertisement

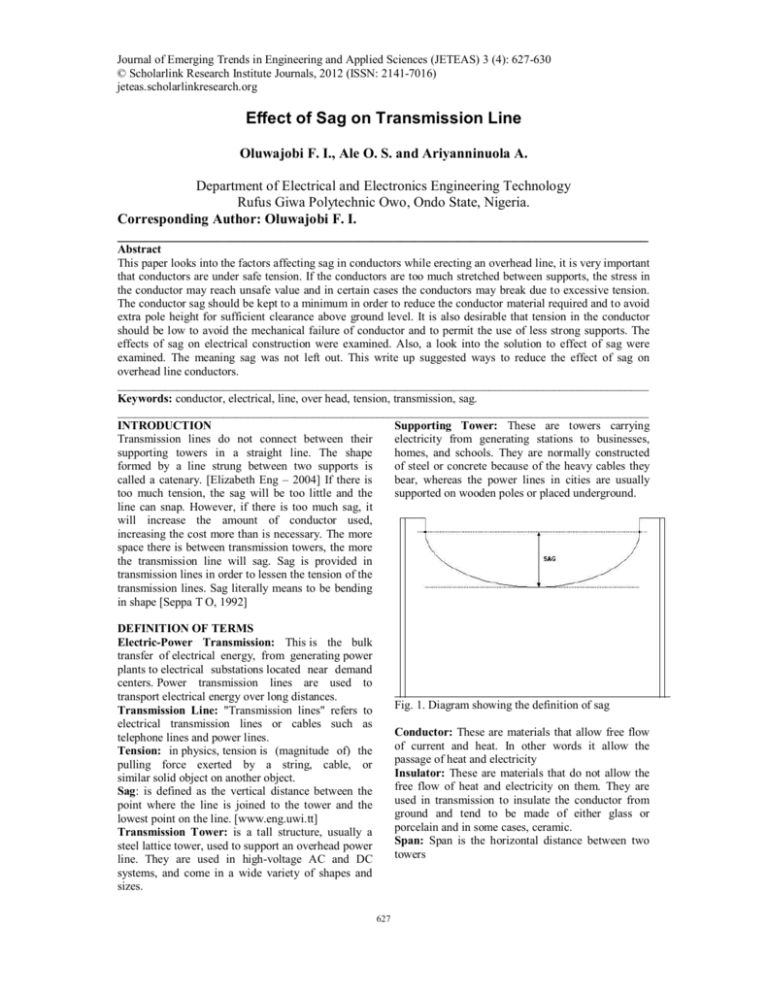

Journal of Emerging Trends in Engineering and Applied Sciences (JETEAS) 3 (4): 627-630 © Scholarlink Research Institute Journals, 2012 (ISSN: 2141-7016) jeteas.scholarlinkresearch.org Journal of Emerging Trends in Engineering and Applied Sciences (JETEAS) 3(4) 627-630 (ISSN: 2141-7016) Effect of Sag on Transmission Line Oluwajobi F. I., Ale O. S. and Ariyanninuola A. Department of Electrical and Electronics Engineering Technology Rufus Giwa Polytechnic Owo, Ondo State, Nigeria. Corresponding Author: Oluwajobi F. I. ___________________________________________________________________________ Abstract This paper looks into the factors affecting sag in conductors while erecting an overhead line, it is very important that conductors are under safe tension. If the conductors are too much stretched between supports, the stress in the conductor may reach unsafe value and in certain cases the conductors may break due to excessive tension. The conductor sag should be kept to a minimum in order to reduce the conductor material required and to avoid extra pole height for sufficient clearance above ground level. It is also desirable that tension in the conductor should be low to avoid the mechanical failure of conductor and to permit the use of less strong supports. The effects of sag on electrical construction were examined. Also, a look into the solution to effect of sag were examined. The meaning sag was not left out. This write up suggested ways to reduce the effect of sag on overhead line conductors. __________________________________________________________________________________________ Keywords: conductor, electrical, line, over head, tension, transmission, sag. __________________________________________________________________________________________ INTRODUCTION Supporting Tower: These are towers carrying Transmission lines do not connect between their electricity from generating stations to businesses, supporting towers in a straight line. The shape homes, and schools. They are normally constructed formed by a line strung between two supports is of steel or concrete because of the heavy cables they called a catenary. [Elizabeth Eng – 2004] If there is bear, whereas the power lines in cities are usually too much tension, the sag will be too little and the supported on wooden poles or placed underground. line can snap. However, if there is too much sag, it will increase the amount of conductor used, increasing the cost more than is necessary. The more space there is between transmission towers, the more the transmission line will sag. Sag is provided in transmission lines in order to lessen the tension of the transmission lines. Sag literally means to be bending in shape [Seppa T O, 1992] DEFINITION OF TERMS Electric-Power Transmission: This is the bulk transfer of electrical energy, from generating power plants to electrical substations located near demand centers. Power transmission lines are used to transport electrical energy over long distances. Transmission Line: "Transmission lines" refers to electrical transmission lines or cables such as telephone lines and power lines. Tension: in physics, tension is (magnitude of) the pulling force exerted by a string, cable, or similar solid object on another object. Sag: is defined as the vertical distance between the point where the line is joined to the tower and the lowest point on the line. [www.eng.uwi.tt] Transmission Tower: is a tall structure, usually a steel lattice tower, used to support an overhead power line. They are used in high-voltage AC and DC systems, and come in a wide variety of shapes and sizes. Fig. 1. Diagram showing the definition of sag Conductor: These are materials that allow free flow of current and heat. In other words it allow the passage of heat and electricity Insulator: These are materials that do not allow the free flow of heat and electricity on them. They are used in transmission to insulate the conductor from ground and tend to be made of either glass or porcelain and in some cases, ceramic. Span: Span is the horizontal distance between two towers 627 Journal of Emerging Trends in Engineering and Applied Sciences (JETEAS) 3(4) 627-630 (ISSN: 2141-7016) WHAT IS SAG? Sag literally means to be bending in shape. In overhead transmission lines, the difference in level between points of supports (towers or utility poles) and the lowest point on the conductor is called sag. are under safe tension. If the conductors are too much stressed between the supports (towers, utility poles), then the stress on the conductors may reach to an unsafe level and the conductor may break due to excessive pressure (i.e. tension). In order to permit safe tension in the conductors, the conductors (i.e. the transmission lines) are not fully stretched but are allowed to have a dip or sag. It Increases the Cost in Transmission Line when Too Much: The more space there is between the transmission towers, the more the transmission line will sag. If there is too much sag in a transmission line, it will increase the amount of conductor used, increasing the cost more than is necessary. Fig. 2: Sag representation It Causes Power Failure: When a transmission line sag excessively, it is liable of causing power failure. An overheating electrical transmission line sagging into a tree sparked the greatest power failure in the Western United States in 1996. A similar incident is suspected to have caused the recent East Coast blackout. ARCHITECTURE There are two subdivisions of a transmission line, with which each end of these subdivisions are terminated by a tension tower. Between these tension towers 5 to 10 supporting towers are used to carry the phase conductors. At the supporting tower insulators are positioned vertically and are aliened with the conductor angle of the tension tower. With respect to load conditions, the tension tower carries both vertical and horizontal loads while the supporting tower carries only the vertical loads. This construction has the advantage that damages that can be impacted by storm is limited to one section. FACTOR AFFECTTING SAGGING IN A TRANSMISSION LINE The factors that affect sagging of transmission lines are: Temperature: As the temperature increases, the outstretched conductor length will increase by an amount equal to: ΔL =αTS…………………………..(i) α = the coefficient of thermal expansion T = the temperature increase in oC S = the span length in meters Why is Sag provided in the Transmission Line? The sag is as a result of the tensioning of the line and must not be too low otherwise the safety clearances may not be met. Also, the sag had to be such that it caters for ice loading in the winter of temperate climates. If the sag is large, and the line becomes heavily loaded, then the sag will further increase and breach the safety clearances. Similarly, if the sag is low, then when the line contracts in the winter, low sag will indicate a high tension, and as a result of this contraction, the line may snap. Sag is inversely proportional to the tension of the line, and is given by the formula below. This will result in increase in sag and decrease in conductor tension [M. Muhr, S. Pack, R. Schwarz, S. Jaufer, 2006] Age: Conductor sag over time may increase due to the effects of strand settling in and metallurgical creep. A higher tension may be used when the conductor is first erected to allow for “settling in of conductor strands and for subsequent metallurgical creep of the conductor material WIND: A wind load on the conductor will increase the apparent weight of the conductor resulting in an in increase in tension. The increase in tension will increase the cable length due to elastic stretch by an amount given by given by: ΔL = (To − T) / EA (ii) To = the initial tension in Newton T = the final tension E = the coefficient of elasticity A = the cross section of the conductor in meters. For high tensions, the sag should be small. For low tensions, the sag should be high. Clearances must also be observed when stringing a line. The normal clearances for overhead lines are shown in the table below. [Sag & Tension Data Table, NESC, IEEE 1990] Voltage Level less than 66kV 66kV to 110kV 110kV to 165kV greater than 165kV Clearance to Ground 20 feet (6.1m) 21feet (6.4m) 22feet (6.7m) 23feet (7.0m) EFFECT OF SAG IN TRANSMISSION LINE It Reduces Excessive Tension: While erecting an overhead line, it is very important that the conductors 628 Journal of Emerging Trends in Engineering and Applied Sciences (JETEAS) 3(4) 627-630 (ISSN: 2141-7016) This increase in resultant load will result in an effective sag in an inclined direction with both horizontal and vertical components. Pole movement: Any movement of pole tops due to stay relaxation etc will have the effect of introducing additional length into the span Ice: Ice build up on the conductor will increase the apparent diameter and weight of the conductor. This is not an issue in Queensland however the same approach can be used for calculating loads and sags if bird diverters are installed along a span .Conductor load per unit length, span Conductor tension Level of supporting towers. Another important factor is the required safety clearance of conductors. Safety clearances are of the following; 1. Vertical Clearance: Distance between conductors and ground. 2. Horizontal Clearances: Distance between conductors and distance between conductor and structure [ Reason J., 1995]. How Sagging Line Mitigator (SLiM) Works As high temperature increases conductor length and its sag, SLiM changes its geometry (by contracting) to decrease line length. As conductor temperature returns to normal, SLiM returns (by expanding) to its original shape. The device with no motors or electronic controls remains always ready to respond to the next conductor high temperature excursion [Hardware to Prevent Sagging of Transmission Lines. California Energy commission, fact sheet, 2004]. Tests at the Pacific Gas and Electric Company facilities in July 2002 showed that SLiM reduces the conductor sag significantly to eliminate sag problems. The temperature increase on the transmission lines was 130°F, from 80° to 210°F. The test transmission line reduced the sag by 3 feet 8 inches when compared to the control transmission line. CONCLUSION It has been known that sag on conductors increases the length of conductors used for transmission. Hence there is the need to increase tension by fixing the conductors on pole properly. This will also eliminate possible accident that may arise as a result of sag as living things including human-being can accidentally touch line conductors. How to Prevent Excessive Sagging of Transmission Line Transmission lines that sag under heavy use and high temperatures are the bane of transmission line operators [Electric Transmission week, 2004, publisher of power daily] these lines are not only limited in the amount of power they can carry, but sagging lines run a higher risk of contacting trees and shorting out. A sagging transmission line in Ohio is believed to be the event that triggered last year’s blackout. REFERENCES Doug Leenhouts, eHow contributor, how to determine the Sag in Transmission lines Electric Transmission week, Monday 2 August 2004, from the publisher of power daily, New product takes active approach to limiting line sag NEWS RELEASE California Energy commission, fact sheet, October 1, 2003. Hardware to Prevent Sagging of Transmission Lines. Up until now, utilities have had two basic approaches to dealing with line sag. They could either: Re-engineer the line, monitor it to assure that sag limits are not breached Re-engineering, this typically involves Reducing the distance among the transmission towers because the more the space between transmission towers, the more the transmission line will sag. Raising tower heights and/or re-conducting address the problem but is an expensive solution when compared with monitoring it to assure that sag limits are not breached. Reason J., 1995, Transmission Line Uprating/Dynamic Rating, Electrical World, August 1995, pp 22-25. Sag & Tension Data Table, NESC, IEEE 1990 Seppa T O, Adams Jr. H W, Douglass D A, Coad N, Edris A, Olivier P, Thrash Jr. F R. 1998, Use of Online Tension Monitoring for Real-time Thermal Ratings, Ice Loads, and Other Environmental Effects, CIGRE Meeting 1998, pp 1-5, Paper No. 22-105. Seppa T O, 1992, A Practical Approach for Increasing the Thermal Capabilities of Transmission Lines, IEEE/PES Summer Meeting, pp 1536-1542. Monitoring is a passive approach that manages the problem of sag but doesn’t address the utility’s need to maximize power flows. Seppa T O, 1995, Accurate Ampacity Determination: Temperature-Sag Model for Operational Real-time Ratings, IEEE Transactions on power delivery, pp 1460-1470, V 10 No. 3. Material Integrity Solutions Inc. of Berkeley has developed another approach. The company developed a device called “sagging line mitigator,” or SLiM, 629 Journal of Emerging Trends in Engineering and Applied Sciences (JETEAS) 3(4) 627-630 (ISSN: 2141-7016) Seppa T. O., Cromer, E., Whitlatch, W.F., 1992, Summer Thermal Capabilities of Transmission Lines in Northern California based on a Comprehensive Study on Wind Conditions, IEEE Power Delivery. Stephen R., 1998, Real Time Monitoring – revised document for final comment 18 December 1998,Convenor Cigre Panel SC22, WG12. Transmission Line Reference Book, 345kV and Above, Second Edition, EPRI Report EL-2500, EPRI, Palo Alto, CA, 1982, pp. 415-417 Wook M B, Choi M, Deb A K, 1997, Line-Rating System Boosts Economical Energy Transfer, IEEE Computer Applications in Power, pp 36-39. 630