Document

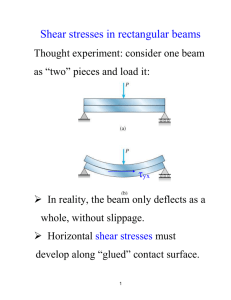

advertisement

4.1 RHEOLOGY1,2 .. is the science that deals with the way materials deform or flow when forces (stresses) are applied to them. AND IT IS AIMED TO 1 … build up mathematical models describing how materials respond to any type of solicitation (forces or deformations). 2 … build up mathematical models able to establish a link between materials macroscopic behaviour and materials micro-nanoscopic structure. 4.2 A cross section area STRESS F h F A cross section area F σ A NORMAL STRESS (N/M2 = Pa) F S h F τ A SHEAR STRESS (N/M2 = Pa) A cross section area DEFORMATION F h L0 L S h F L L0 ε L L ε ln L0 F LINEAR STRAIN HENCKY STRAIN S γ h SHEAR STRAIN 4.3 RHEOLOGICAL PROPERTIES A - ELASTICITY “ A material is perfectly elastic if it returns to its original shape once the deforming stress is removed” HOOKE’s Law (small deformations) Normal stress L L0 σE Eε L E = Young modulus (Pa) Shear stress Incompressible materials E = 3G τ Gγ [SOLID MATERIAL] G = shear modulus (Pa) B - VISCOSITY “ This property expresses the flowing (continuous deformation) resistance of a material (liquid) ” Very often VISCOSITY and DENSITY are used as synonyms but this is WRONG! EXAMPLE: at T = 25°C and P = 1 atm HONEY is a fluid showing high viscosity (~ 19 Pa*s) and low density (~1400 Kg/M3) MERCURY is a fluid showing low viscosity (~ 0.002 Pa*s) and high density (13579 Kg/M3) WATER: viscosity 0.001 Pa*s, density 1000 Kg/m3 NEWTON Law d τ ηγ η dt LIQUID MATERIAL ητ γ Shear rate h = viscosity or dynamic viscosity (Pa*s) n = kinematic viscosity = h/density(m2/s) η f γ, T , structure IF h does not depend on share rate, the fluid is said NEWTONIAN WATER is the typical Newtonian fluid. On the contrary it can be “SHEAR THINNING” 100 h(pa s) 10 1 Legge di potenza Powell - Eyring Cross Carreau Bingham Casson Herschel Shangraw 0.1 0.01 0.1 1 10 100 °(s ) -1 1000 10000 100000 … or “SHEAR THICKENING” (opposite behaviour) Usually h reduces with temperature Why h depends on liquid structure, shear rate and temperature? M M M K(T) M M M K(T) K(T) K(T) K(T) M K(T) Idealised polymer chain z friction coefficient C - VISCOELASTICITY “ A material that does not instantaneously react to a solicitation (stress or deformation) is said viscoelastic” LIQUID VISCOEALSTIC SOLID VISCOEALSTIC deformation t stress t deformation t stress t STRESS Material behaviour depends on: SOLVENT MOLECULES POLYMERIC CHAINS 1 ELASTIC (instantaneous) REACTION OF MOLECULAR SPRINGS 2 VISCOUS FRICTION AMONG: - CHAINS-CHAINS - CHAINS-SOLVENT MOLECULES D – TIXOTROPY - ANTITIXOTROPY A material is said TIXOTROPIC when its viscosity decreases with time being temperature and shear rate constant. A material is said ANTITIXOTROPIC when its viscosity increases with time being temperature and shear rate constant. The reasons for this behaviour is found in the temporal modification of system structure EXAMPLE: Water-Coal suspensions h In the case of viscoelastic systems, no structure break up occurs AT REST: structure MOTION structure break up COAL PARTICLE t 4.4 LINEAR VISCOELASTICITY THE LINEAR VISCOEALSTIC FIELD OCCURS FOR SMALL DEFORMATIONS / STRESSES THIS MEANS THAT MATERIAL STRUCTURE IS NOT ALTERED OR DAMAGED BY THE IMPOSED DEFORMATION / STRESS .. consequently, linear viscoelasticty enables us to study the characteristics of material structure MAIN RESULTS Shear stress Normal stress τt G γ0 σt E ε0 Et 3Gt Shear modulus G does not depend on the deformation extension 0 Tensile modulus E does not depend on the deformation extension e0 Incompressible materials G(t) or E(t) estimation 1) MAXWELL ELEMENT1,2 g h t γ 0 ge t λ λη g t τ Gt ge λ γ0 E(t) = 3 G(t) 120 solid 0 l = 10 s G (Pa) [1 element] 0 is instantaneously applied 100 80 l =1s 60 40 liquid 20 l = 0.1 s 0 0 1 2 3 t (s) 4 5 6 2) GENERALISED MAXWELL MODEL1,2 g1 g2 h1 g3 h2 g4 h3 g5 h4 h5 0 0 is instantaneoulsy applied N t γ 0 g i e t λi λ i ηi g i i 1 Gt t γ0 N gi e i 1 t λi E(t) = 3 G(t) 120 l 1 = 0.22 s g1 = 90 Pa l 2 = 4.44 s g2 = 9 Pa l 3 = 88.88 s g3 = 0.9 Pa G (Pa) [more elements] 100 l =1s l 4 = 1600 s 80 g4 = 0.1 Pa 60 40 20 0 0 1 2 3 t (s) 4 5 6 SMALL AMPLITUDE OSCILLATORY SHEAR 1.5 w = 1 s-1 g1 g2 g3 g4 w = 10 s-1 1 g5 h1 h2 h3 h4 h5 / 0 0.5 0 0 1 2 3 4 -0.5 -1 (t) = 0sin(wt) -1.5 w = 2pf f = solicitation frequency t (s) 5 6 7 On the basis of the Boltzmann1 superposition principle, it can be demonstrated that the stress required to have a sinusoidal deformation (t) is given by: (t) = 0sin(wt+d) d(w) = phase shift (t) = 0*[G’(w)*sin(wt) + G’’(w)*cos(wt)] (t) = 0sin(wt) Gd= 0/0=(G’2+G”2)0.5 G’(w) = Gd*cos(d) = storage modulus G’’(w) = Gd*sen(d) = loss modulus tg(d)=G”/G’ 1.5 / 0 d3.14 LIQUID G’≈ 0 G”≈ Gd 1 0.5 d 0.314 0 0 -0.5 -1 1 2 3 4 / 0 SOLID G’≈ Gd G”≈ 0 -1.5 t (s) 5 6 7 According to the generalised Maxwell Model, G’ and G” can be expressed by: g i λ i ω G 2 i 1 1 λ i ω 2 N ' li = hi/gi gi λiω G 2 i 1 1 λ i ω N " g1 g2 h1 g3 h2 h3 g4 h4 (t) = 0sin(wt) g5 h5 In the linear viscoelastic field, oscillatory and relaxation tests lead to the same information: g i λ i ω G 2 i 1 1 λ i ω 2 N ' Oscillatory tests gi λiω G 2 i 1 1 λ i ω N " N Relaxation tests G t g i e i 1 t λi 4.5 EXPERIMENTAL1 SHEAR DEFORMATION/STRESS Rotating plate Gel Fixed plate SHEAR RATE CONTROLLED SHEAR STRESS CONTROLLED STRESS SWEEP TEST: constant frequency (1 Hz) 100000 G’(Pa) (elastic or storage modulus) Linear viscoelastic range (t) = 0sin(wt) w = 2pf 10000 G’’(Pa) (loss or viscous modulus) 1000 1 10 100 0 (pa) 1000 10000 FREQUENCY SWEEP TEST: constant stress or deformation τt τ 0 sin ωt 0 = constant; 0.01 Hz ≤ f ≤ 100 Hz 100000 G’ (Pa) 10000 G’’ (Pa) 1000 0.01 0.1 1 10 w (rad/s) 100 1000 n 1 (λ i ω) 2 G' Ge g i ; 2 1 (λ i ω) i 1 λ i ηi g i ω λi G' ' gi ; 2 1 (λ i ω) i 1 gi n hi (t) 100000 G’ (Pa) 10000 Fitting parameters gi, hi, n Black lines: model best fitting G’’ (Pa) 1000 0.01 0.1 n 1 10 w (rad/s) 100 1000 G gi i 1 li+1 =10* li 0th Maxwell element (spring) -------> 1 fitting parameter (ge) 1st Maxwell element -------> 2 fitting parameters (g1, l1) 2nd Maxwell element ------->1 fitting parameters (g2, l2) 3rd Maxwell element -------> 1 fitting parameters (g3, l3) 4th Maxwell element -------> 1 fitting parameters (g4, l4) 0.01 Np 0.001 Np = generalised Maxwell model fitting parameters 0.0001 0.00001 0.000001 2 3 4 5 N p*c 6 2 7 8 4.6 FLORY THEORY3 Polymer Solvent Polymer Solvent ≈ Crosslinks SWELLING EQUILIBRIUM SOLVENT mgH2O = msH2O D=mgH2O - msH2O = 0 D = DM + DE + DI = 0 Mixing Elastic Ions DE = -RTrx(np/np0)1/3 G ρx RT νp ν p0 23 n G gi i 1 rx = crosslink density in the swollen state np = polymer volume fraction in the swollen state np0 = polymer volume fraction in the crosslinking state T = absolute temperature R = universal gas constant gi = spring constant of the Maxwell ith element Comments 1 The use of Flory theory for biopolymer gels, whose macromolecular characteristics, such as flexibility, are far from those exhibited by rubbers, has been repeatedly questioned. 2 However, recent results have shown that very stiff biopolymers might give rise to networks which are suitably described by a purely entropic approach. This holds when small deformations are considered, i.e. under linear stress-strain relationship (linear viscoelastic region)9. 3 G can be determined only inside the linear viscoelastic region. 4.7 EQUIVALENT NETWORK THEORY4 x x x Polymeric chains SAME CROSS-LINK DENSITY (rx) 3 4 ξ 1 π 3 2 ρx NA REAL NETWORK TOPOLOGY ξ 3 6 πρ x N A EQUIVALENT NETWORK TOPOLOGY REFERENCES 1) Lapasin R., Pricl S. Rheology of Industrial polysaccharides, Theory and Applications. Champan & Hall, London, 1995. 2) Grassi M., Grassi G. Lapasin R., Colombo I. Understanding drug release and absorption mechanisms: a physical and mathematical approach. CRC (Taylor & Francis Group), Boca Raton, 2007. 3) Flory P.J. Principles of polymer chemistry. Cornell University Press, Ithaca (NY), 1953. 4) Schurz J. Progress in Polymer Science, 1991, 16 (1), 1991, 1.