UNIVERSITA` DEGLI STUDI DI BRESCIA FACOLTA` DI

advertisement

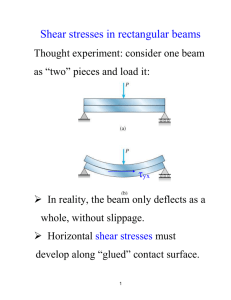

Resistenza a taglio di travi in calcestruzzo fibrorinforzato Giovanni Plizzari Università degli Studi di Brescia giovanni.plizzari@unibs.it RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17th, 2015 Giovanni Plizzari Outlines Shear Action Factor affecting the shear strength Experimental tests on PC and FRC beams Wide-shallow beams in FRC Shear Design of FRC beams RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 2 Giovanni Plizzari Optimized reinforcement: definition Place the best performing reinforcement (fibers and/or rebars) where required by tensile stresses in the structural elements RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 3 Giovanni Plizzari Reinforcement use in structural elements • In structural elements both distributed and localized stresses are generally present • Conventional rebars represent the best reinforcement for localized stresses • Fibers represent the best reinforcement for diffused stresses • Structural optimization generally requires the use of a combination of rebars and fibers • Structural ductility is generally enhanced RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 4 Giovanni Plizzari Mechanisms of Shear Transfer Uncracked concrete zone Unterface shear transfer Dowel action Residual tensile stress across cracks RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 5 Giovanni Plizzari Shear in beams without stirrups In FRC elements there is an additional contribution to shear resistance provided by fiber reinforcement: V = Vc + Vf Vc represents the concrete contribution. Vf represents the fiber contribution (post cracking strength). RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 6 Giovanni Plizzari Shear in beams with stirrups V = Vc + Vw + Vf RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 7 Factor affecting the shear strength Giovanni Plizzari Tensile strength of concrete Longitudinal reinforcement ratio Shear span-to-Depth ratio (a/d) Axial forces Coarse aggregate size Size effect RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 8 Giovanni Plizzari Factors affecting the Shear Strength Distribution of longitudinal reinforcement along beam height (fiber?) RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 9 Size effect RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 Giovanni Plizzari 10 Giovanni Plizzari Experimental campaign on PC and FRC beams V V Campaign I 2Ø24 Bars, L=4550 mm 480 mm d a 4350 mm 200 8 beams NSC 3 beams HSC 45 480 Steel Plate 200x90x30 mm 2Ø24 Deformed Bars 45 a/d=2.5 Longitudinal reinforcement ratio 1% No stirrups RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 11 Giovanni Plizzari Experimental campaign on PC and FRC beams 400 Normal Strength Concrete, f'c = 24.8 MPa 30 kg/m3, 30/0.6 30 kg/m3, 30/0.6 + 15 kg/m3, 12/0.18 30 200 V 100 NSC1-PC NSC1-FRC1 NSC1-FRC2 V 30 Ø 0.38 Load [kN] 300 0 60 f’c = 24.8 MPa30 3 30 kg/m3, 30/0.6 + 15 kg/m3, 12/0.18 30 kg/m3, 30/0.6 Fibers: 30 0.38% macro-fibres, 30 mm long with an aspect ratio of 50 50 V 1 TPT V V NSC1-PC NSC1-FRC1 NSC1-FRC2 0.19% micro-fibres, 12 mm long 12 with an aspect ratio of 66.7 0 0 100 200 Load [kN] 300 12 Ø 1.0 V Average First CPT Cracking 30 Ø 0.18 Crack Width [mm] Normal Strength Concrete, f'c = 24.8 MPa 2 30 80 Ø 0.18 40 Displacement [mm] Ø 0.62 20 Ø 0.6 0 400 RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 12 Giovanni Plizzari Experimental campaign on PC and FRC beams 500 50 kg/m3, 80/30 Fibers: 50 kg/m3, 45/30 300 30 Ø 0.62 0.6% macro-fibers, 200 Normal strength fibers (45/30) HSC-PC HSC-FRC1 HSC-FRC2 100 0 0 20 40 Displacement [mm] 60 80 V CPT HSC-PC HSC-FRC1 HSC-FRC2 1 0.5 V 50 kg/m3, 45/30 A relative small amount of fibers signifiantly enhances both the shear capacity and the ductility, both in case of normal strength concretes and high strength concretes V V 12 TPT 1.5 50 50 3 30 Ø 0.18 Crack Width [mm] Average First Cracking fibers 30 High Strength Concrete 2 30 Ø 0.18 2.5 High strength (80/30) 30 ØØ0.38 0.6 V Ø 0.62 V 50 kg/m , 80/30 12 0 0 100 200 300 Load [kN] 400 500 RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 13 Ø 0.6 Load [kN] 400 Ø 0.38 f’c = 60 MPa. High Strength Concrete Giovanni Plizzari Experimental campaign on PC and FRC beams Fibre 50/1.0 No fibre PC beams: very brittle and sudden failure FRC: prior warning of impending collapse, more distributed crack pattern Fibre 80/30 RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 14 Final crack patterns PC Giovanni Plizzari Fibres 45/30 90 kN 150 kN Failure Fibres control and stabilize the shear crack propagation The combination of macrofibres with micro-fibres lead to a better crack control at small and high values of crack opening. Fibres 80/30 90 kN 150 kN Failure RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 15 Giovanni Plizzari Size effect Beams without web reinforcement fail when inclined cracking occurs or shortly afterwards. The inclined cracking load of a beam is affected by many principal variables. One of these is the size of beam (size effect). An increase in the effective depth of a beam results in a decrease of the shear bearing capacity. d vu = Vu bw d Ohio shear collapse (1955) RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 16 Giovanni Plizzari Experimental campaign II a a d d 2Ø24 Bars, L=4550 mm 4350 mm 200 L=4600 mm 6Ø206Ø20 Bars, Bars, L=4600 mm 4550 mm 4550 mm 4600 mm 4600 mm Steel Plate 200x90x30 mm 200 200 2Ø24 Deformed Bars Steel Plate 200x90x30 mm 1000 45 1000 45 480 P P 1000 mm V 1000 mm V 480 mm d a 45 11 beams Steel Plate 6Ø20 Deformedmm Bars 200x90x30 45 6Ø20 Deformed Bars a/d=2.5 Longitudinal reinforcement ratio 1% NSC e HSC (f’c =25.7 and 55 MPa) H=500 mm and H=1000 mm RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 17 Giovanni Plizzari Experimental campaign II 500 800 Load Displacement Curve Load-Displacement Curve Small Size Specimens H = 500 mm; fc = 25.7 MPa Large Size Specimens H = 1000 mm; fc = 25.7 MPa 400 300 P 200 Load [kN] Load [kN] 600 d PC-100 MSR-100 PC-50 FRC-50 20 kg/cm Test 1 FRC-50 20 kg/cm Test 2 MSR-50 Test 1 MSR-50 Test 2 100 400 200 P FRC-100 20 kg/cm d 0 0 0 3 6 9 12 15 0 3 6 9 12 15 Displacement [mm] Displacement [mm] Small and Large Size Specimens, f’c=25.7 MPa. FRC beams: Steel fibres 0.25% l=50 mm Aspect ratio= 50 Minimum shear reinforcement: MSR-50 with 2f8@300mm, 2f8@650mm RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 MSR-100 with 18 Giovanni Plizzari Experimental campaign III 1000 5 Crack Width [mm] 4 Large Size Specimens Load [kN] H = 1000 mm; fc = 55 MPa 800 P Large Size Specimens H = 1000 mm; fc = 55 MPa P TPT5 TPT2 d TPT4 TPT1 P 600 3 TPT6 400 TPT3 2 H-PC-100 H-PC-100 H-MSR-100 H-MSR-100 H-FRC-100 200 1 H-FRC-100 Displacement [mm] Load [kN] 0 0 0 5 10 15 20 0 200 400 600 800 1000 Large Size Specimens, f’c=55.0 MPa. The same amount of fibers Stable propagation of cracks, higher ductility and shear capacity, prior warning of impeding collapse. RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 19 Giovanni Plizzari Experimental campaign IV SPECIMEN PC-50 MSR-50 1 MSR-50 2 FRC-50 1 FRC-50 2 PC-100 MSR-100 NSC FRC-100 PC-100 MSR-100 HSC FRC-100 Pu vu [kN] [MPa] 216 1.22 346 1.93 302 1.69 388 2.16 308 1.72 365 1.07 635 1.81 494 1.42 393 1.14 880 2.48 656 1.86 vu/(fc)1/2 u Vu/Vu,FL [-] 0.24 0.38 0.33 0.43 0.34 0.21 0.36 0.28 0.15 0.33 0.25 [mm] 2.74 9.33 7.03 10.95 4.77 7.60 12.60 11.05 9.79 18.62 12.01 [-] 0.52 0.82 0.72 0.92 0.73 0.43 0.73 0.57 0.45 0.99 0.74 Fibres can completely substitute the minimum amount of shear reinforcement 20-30 kg/m3 is the amount required in many structural applications Fibres resulted less effective than the minimum amount of shear reinforcement on the size effect. RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 PC H100 MSR H100 FRC-20 H100 20 Giovanni Plizzari Numerical Analyses NFEA 1.4 Size Effect on PC and FRC Members Vu,num v= bw d gc= 1, rs= 1%, NSC f'c= 22 MPa, HSC f'c= 58.3 MPa 1.2 Skin Reinforcement Recommended v/vmax,flex [-] 1 M u,flex vmax,flex = 2.5 b w d 2 0.8 feq(0.6-3) 0.6 HSC-FRC3 NSC-FRC2 NSC-FRC1 NSC-PC exp PC exp FRC 0.4 0.2 0 0 500 1000 1500 2000 2500 Effective Depth [mm] RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 d from 250 to 2000 mm. Increasing the fiber toughness, the size effect influence decreases 21 Giovanni Plizzari Experimental Program on DEEP BEAMS H=500 mm 9 full scale beams a/d=3.0 ρ= 1% NSC (fcm =35 MPa) H=1000 mm H=500 mm H=1000 mm H=1500 mm H=1500 mm 0, 50 or 75 kg/m3 of steel fibers (SFRC) No stirrups anywhere RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 22 Giovanni Plizzari Deep beams: Experimental results Fibers enhance the ductility and the shear bearing capacity (50 kg/m3 of fibers doubled the shear strength). ULS Fibers increase the load at which the shear crack becomes unstable. PC - max shear crack = 0.2-0.5 mm; FRC - max shear crack = 3-4 mm Beams H1000 RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 23 Giovanni Plizzari Deep beams: Experimental results Fibers enhance the behavior at Serviceability Limit State as well. A significant enhanced post-cracking stiffness is observed in FRC beams, which is mainly due to the bridging effect of fibers. SLS Fibers improve the durability of structural elements Beams H1500 Beams H1500 RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 24 Giovanni Plizzari Deep beams: Crack patterns In FRC elements: MULTIPLE SHEAR CRACKS STABLE SHEAR CRACKS Progressive formation of multiple cracks, with a stable propagation. Fibers are highly effective in controlling development and propagation of cracking Fibers more distributed crack pattern, with more closely spaced and smaller cracks H1500 FRC50 H=1500 mm RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 25 Giovanni Plizzari Deep beams in PFRC: Experimental results Unlike MSR samples (rmin=0.17%), shear failure was observed in PFRC beams. PP fibres enhanced the ultimate shear strength and ductility of deep beams, which are much more critical in shear than WSBs. 13 kg/m3 of PP fibres was able to double both the shear strength and the ductility, as compared to control samples PP fibres were found to be effective also in presence of prestressing Vu vu vu/(fcm)1/2 [kN] [MPa] [-] Shear 183 0.80 0.15 MSR 300x800-1 Flexure 424 1.86 0.34 MSR 300x800-2 Flexure 436 1.91 0.35 PFRC 300x800-1 Shear 381 1.67 0.29 PFRC 300x800-2 Shear 405 1.77 0.30 PC 150x800-1 Shear 91 0.80 0.15 PC 150x800-2 Shear 101 0.88 0.16 MSR 150x800-1 Flexure 244 2.13 0.39 MSR 150x800-2 Flexure 250 2.18 0.40 PFRC 150x800-1 Shear 205 1.79 0.31 PFRC 150x800-2 Shear 247 2.16 0.37 PC 150x800 PT-1 Shear 199 1.73 0.31 PFRC 150x800 PT-1 Shear* 284 2.49 0.42 PC 150x600-1 Shear 89 1.05 0.19 PC 150x600-2 Shear 64 0.76 0.14 MSR 150x600-1 Flexure 185 2.19 0.40 MSR 150x600-2 Flexure 204 2.42 0.44 PFRC 150x600-1 Shear 166 1.96 0.34 PFRC 150x600-2 Shear 198 2.35 0.40 Specimen PC 300x800-1 RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 Failure mode 26 Giovanni Plizzari Deep beams in PFRC: Experimental results PP fibres and MSR increase the load at which shear crack becomes instable PP fibres have been able to slightly increase the post-cracking stiffness Flexural crack spacing was 20% smaller in PFRC deep beams 1000 8 Deep Beams 300x800 Load 900 [kN] d=761 mm 800 6 5 PC 300x800-1 MSR 300x800-1 500 MSR 300x800-2 400 PFRC 300x800-1 d=761 mm PC 300x800-1 MSR 300x800-1 MSR 300x800-2 PFRC 300x800-1 PFRC 300x800-2 700 600 Deep Beams 300x800 Crack Width 7 [mm] 4 P/2 V 3 PFRC 300x800-2 300 P/2 2 P/2 200 1 100 Mid-span deflection [mm] Load [kN] 0 0 0 5 10 15 20 25 30 35 40 45 0 200 400 RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 600 800 1000 27 Giovanni Plizzari Prestressed Double tees 6 full-scale double tees H=500mm; d=390 mm; L=6000mm bw=120 mm 3 tendons 0.6” ρl=0.89% 2 double tees WR1 DT 1 double tees WR2+SCPFRC DT RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 28 Prestressed Double Tees Giovanni Plizzari 3 double tees SCPFRC-DT 10kg/m3 of PP fibres (Vf=1.10%) RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 29 Giovanni Plizzari Tests in zone with uniform prestressing 3 experimental tests a/d ≈ 3 WR1 DT-1 (RC) SCPFRC DT-1 (only PP fibres) SCPFRC DT-2 (only PP fibres) RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 30 Giovanni Plizzari Tests in zone with uniform prestressing All specimens showed a shear failure +10-15% +70-240% Both PP fibres and MSR led to: - An increment of the shear capacity of about 10-15% - An increment of the ductility at least of 70%. Shear crack PP fibres can completely substitute the minimum amount of shear reinforcement RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 31 Tests in the end zone Giovanni Plizzari 6 experimental tests a/d ≈ 3 WR1 DT-2 a/b (RC) SCPFRC DT-3 a/b (only PP fibres) WR2+SCPFRC DT a/b (RC + PP fibers) RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 32 Giovanni Plizzari Tests in the end zone +15% The more effective solution in the end zones seems to be the combination of PP fibres and conventional reinforcement (steel wire mesh Ø5 200x300), in which after shear cracking a stable behaviour with an increment (+20%) of the ultimate bearing capacity was observed. RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 33 Giovanni Plizzari Wide-Shallow Beams (WSBs) Typical structure typology of residential building in: Southern Europe, Australia, Middle-East, Central and South-America. Beam Topping concrete layer RC spandrel wide-shallow beam Lightweight ribbed one-way reinforced concrete slab RC central wide-shallow d beam b d≥b d b Wide-shallow beam d 2d ≤ b b Benefits: floors completely flat, more architectural flexibility, easier formwork Disadvantages: deformability, small net span, transfer of load to column. RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 34 Giovanni Plizzari Experimental campaigns on WSBs FIRST EXP. CAMPAIGN SECOND EXP. CAMPAIGN 16 full scale WSBs 14 full scale WSBs Main purposes: 1) Study both shear and flexure behavior of WSBs 2) Evaluate the possibility of completely substitute the minimum amount of shear reinforcement by steel fibers (SFRC) Main purposes: 1) Study the shear behavior of PC wide-shallow beams 2) Evaluate structural polymer fibers in full scale tests 3) Replace the minimum shear reinforcement by polymer fibers (PFRC) RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 35 Giovanni Plizzari SFRC and PFRC WSBs: Experimental results Either minimum shear reinforcement or fibers greatly influences the shear behavior of wide-shallow beams (by altering the collapse from shear to flexure, with enhanced bearing capacity and ductility). Both STEEL FIBERS and POLYPROPYLENE FIBERS have been able to completely substitute the minimum amount of transverse reinforcement. 13 kg/m3 SFRC PFRC RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 36 Giovanni Plizzari FRC WSBs: Flexure behavior Steel fibers even in small amount, provides a greater flexure bearing capacity and increases the overall ductility under flexure, due to the positive effect in increasing the compression softening. In the case of PFRC WSBs this behavior is less pronounced. μδ=4.3 SFRC (+6%) (+10%) +40% μδ=6.1 (+7%) (+10%) RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 37 Giovanni Plizzari Shear design of FRC elements Shear strength without shear reinforcement 0.18 1 3 VRd k (100 r1 f ck ) 0.15 CP bW d gc Modified in MC2010 in order to consider fibres contribution - Fibres contribution included in the shear concrete strength - Fibres contribution is taken into account considering the residual strengths according to EN14651 (3PBT) RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 38 Shear design of FRC elements Giovanni Plizzari 3 0.18 f Ftuk k 100 r1 1 7.5 f 0 . 15 ck cp bW d f ctk g c 1 VRd,F [tensio fFtuk characteristic value of the residual strength (SLU), considering wu = 1.5 mm, in MPa; f Ftu f R3 3 This model has been adopted by Model Code 2010 (MC2010) RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 39 Giovanni Plizzari Shear Strength vs. Toughness 2.40 Range used in structural application New model for FRC w/o stirrups 2.20 Vu,FRC/Vu,EC2 [-] 2.00 1.80 1.60 fctm = 2.0 MPa fctm = 2.5 MPa 1.40 fctm = 3.0 MPa fctm = 3.5 MPa 1.20 [MPa] eq(0.6-3) MPa ffFtu fctm = 4.0 MPa fctm = 5.0 MPa 1.00 0 1 2 3 4 5 6 7 8 9 The shear strength significantly increases using fibres RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 40 Giovanni Plizzari MC2010 model vs experimental results 2.50 fib vs. RILEM 2.25 2.00 RILEM DATA Conservative BRESCIA DATA Vu,exp/Vu,model 1.75 1.50 1.25 1.00 0.75 0.50 fib Unconservative RILEM 0.25 0.00 0 5 10 15 20 25 30 35 40 45 50 55 60 Test # MC2010 model seems to be consistent RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 41 Giovanni Plizzari Minimum shear reinforcement 1.75 • Crack control • Ductility • Warning of impending collapse Minimum FRC Transverse Reinforcement 1.50 f eq , min 0 . 7 feq(0.6-3) [MPa] 1.25 f ck 4 .5 Calculation Design Formulation Best Fitting Formulation 1.00 0.75 0.50 r w,min 0.08 f ck f yk f eq ,min 0.25 3 0.008 f ck f ct 1 1 2.5 0.18 k 100 r f ck 1 / 3 0.00 20 V Rd ,ct , FIBERSVRd ,ct 0.08 f eq,min f ck bw d 3 0 . 008 f f ct ck 1 1 1/ 3 2.5 0.18 k 100 r f ck 40 60 100 Compressive Strength [MPa] f Ftuk RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 80 f ck 20 42 Giovanni Plizzari MC2010 – Shear Workshop Salò Ottobre 2010 RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 43 Giovanni Plizzari Example of Application for Shear: I 2Ø24 Bars 500 200 500 mm d p = 35 kN/m 2Ø24 Deformed Bars 6m 1 1 2 M max p l 35 62 157.5 kN m 8 8 h 500 mm; d 460 mm 1 1 Vmax p l 35 6 105 kN f ck 30 MPa; f yk 500 MPa 2 2 g c 1.5; g s 1.15 As 904 mm 2 rl 0.98% 30 500 bw d 200 mm 460 mm f cd 20 MPa; f yk 435 MPa 1.5 1.5 M u 161 kN m f ctk 2 MPa ( EC 2) pu 35 kN / m (ULS ) RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 44 Giovanni Plizzari Example of Application for Shear: I VRd ,ct 0.18 1 3 k (100 r1 f ck ) 0.15 CP bW d 49 kN gc Minimum Shear Reinforcement 1.6 1.4 3.2 meters requiring design shear reinforcement; 2.8 meters requiring minimum shear reinforcement. Design Shear Reinforcement: Minimum Shear Reinforcement: s 0.75 d 345 mm Asw r w,min 0.08 f ck f yk 2 6 @ 300 mm VR ,ds 0.0009 z f yd VRd VRd ,ct 56 kN s s 321 mm 28@ 300 mm RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 45 Example of Application for Shear: I Giovanni Plizzari Assume 30 kg/m3 of steel fibers having l/f =67 and fFtk,u=0.90 MPa (tested at the University of Brescia) f Ftk ,u 0.18 1 VRd , F k (100 r1 (1 7.5 ) f ck ) 3 0.15 CP bW d f ctk gc VRd , F 0.18 200 0.90 1 3 1 ) 20) 200 460 81 kN (100 0.0098 (1 7.5 460 2 1.5 Minimum shear reinforcement f Ftuk f ck 20 Minimum Shear Reinforcement 30 0.27 MPa OK 20 Design Shear Reinforcement 0.7 2.3 A VR ,ds sw z f yd VRd VRd ,ct 24 kN s 26@ 300 mm s 420 mm RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 46 Example of Application for Shear: I 2Ø8@300mm 2Ø6@300mm Giovanni Plizzari Plain concrete 2Ø6@300mm FRC RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 47 Giovanni Plizzari Example of Application for Shear: WSBs 500 cm 500 cm g = 40 kN/m WSBs q = 10 kN/m H = 30 cm Concrete B450C h 500 mm; C30/37 d 460 mm d = 26 cm ϒfck 30 MPa; f yk 500 MPa b = 80 cm pu 35 kN / m (ULS ) g c 1.5; g s 1.15 30 500 f cd 20 MPa; f yk 435 MPa 1.5 1.5 f ctk 2 MPa ( EC 2) 80 ϒ RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 30 d=26cm 40+10 kN/m 48 Giovanni Plizzari Example of Application for Shear: WSBs Shear design according to Level I of Model Code 2010 (inclination of the compressive stress field of 30°). MSR MSR Steel incidence on concrete volume: 145 kg/m3 RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 49 Giovanni Plizzari Example of Application for Shear: WSBs FRC classified as 3c (fR1k=3MPa; fR3k=3MPa, i.e. 35 kg/m3 of steel fibres 60 mm long with diameter of 0.75 mm) MSR by fibres MSR by fibres Steel incidence on concrete volume: 115 kg/m3 RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 50 Giovanni Plizzari Thank you for your kind attention University of Brescia RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 51 Giovanni Plizzari Examples of Shear Design: II 500 160 L=10 m 160 120 680 40 1000 p (UDL) 1- Given material properties (NSC) and reinf. details, calculation of Mrd; 2- Corresponding ultimate load (UDL) pu=8Mrd/l2; 3- Design ultimate shear Vrd=1.1 pu l (-pu 1m) where 1.1 is a incremental safety factor to guard against brittle collapse phenomena; 4- Concrete contribution to shear without fibers, fiber contribution, concrete+fiber (Vcd,FIBERS) contribution; 5- Asw/s ratio necessary to fully reach the required shear capacity Vrd, being Vwd=Asw/s 0.9 d fywd = Vrd – Vcd,FIBERS; 6- Transverse reinforcement saving ratio due to fibers as: Asw / s FIBRES S .R. 1 Asw / s NO FIBRES RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 52/20 52 Giovanni Plizzari Examples of Shear Design: II 90 Fibre Contribution to Shear Prestressed and not-Prestressed Member 80 CNR rho = 0.8% 70 Fibre Contribution [kN] Parameters: -prestressing; -Fiber toughness; -Reinforcement ratio. RILE M Model CNR rho = 1% CNR rho = 1.2% 60 r CNR rho = 1.4% CNR rho = 1.6% 50 CNR model is equal to MC2010 one Model RILEM all rho 40 30 RILEM does not depends on the reinforcement ratio. 20 fR3=0.90feq(0.6-3) 10 1 1.5 2 2.5 3 3.5 4 4.5 5 feq(0.6-3) [MPa] RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 V f 0.7 k f kl fd bw d 0 Linear trend vs. feq 53/20 53 Giovanni Plizzari Examples of Shear Design: II 180 Concrete + Fibre Shear Contribution Prestressed Member 300 Concrete + Fibre Contribution [kN] Concrete + Fibre Contribution [kN] 350 r 250 200 150 100 CNR RILEM Concrete + Fibre Shear Contribution Not-Prestressed Member 160 140 r 120 100 80 CNR RILEM 60 50 40 0 1 1.5 2 2.5 3 3.5 4 4.5 5 1 1.5 feq(0.6-3) [MPa] 2 2.5 3 3.5 4 4.5 feq(0.6-3) [MPa] Good agreement up to feq(0.6-3)<3 MPa, which covers most of practical applications (for strain-softening materials). RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 54/20 54 5 Giovanni Plizzari Examples of Shear Design: II Stirrup Saving ratio S .R. 1 Asw / s FIBRES Asw / s NO FIBRES 1.20 0.40 1-(Asw/s,FIBRES)/(Asw/s,NO FIBRES) [-] 0.35 1-(Asw/s,FIBRES)/(Asw/s,NO FIBERS) [-] Transverse Shear Reinforcement Saving Ratio Not-Prestressed Member Transverse Shear Reinforcement Saving Ratio Prestressed Member 0.30 CNR 0.25 RILEM 0.20 0.15 0.10 r 1.00 CNR 0.80 RILEM 0.60 0.40 r 0.20 0.05 0.00 0.00 1 1.5 2 2.5 3 3.5 4 4.5 5 1 1.5 2 2.5 3.5 3 4 4.5 feq(0.6-3) [MPa] feq(0.6-3) [MPa] RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 55/20 55 5 Giovanni Plizzari Pictures at failure W770 PC AND W770 FRC-2 PC 15x60 A and FRC 15x80 B RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 56 Giovanni Plizzari Examples of Shear Design: II 1.00 0.90 0.80 0.80 0.70 0.70 0.60 0.60 0.50 CNR rho = 0.8% 0.40 L'/L RILEM Not-Prestressed Member 0.90 L'/L [-] L'/L [-] 1.00 L'/L CNR Not-Prestressed Member 0.50 RILEM rho = 0.8% 0.40 RILEM rho = 1% CNR rho = 1% 0.30 0.30 RILEM rho = 1.2% CNR rho = 1.2% 0.20 0.10 CNR rho = 1.4% 0.20 CNR rho = 1.6% 0.10 RILEM rho = 1.4% RILEM rho = 1.6% 0.00 0.00 1 1.5 2 2.5 3 3.5 4 4.5 5 1 1.5 2 2.5 3 3.5 4 4.5 5 feq(0.6-3) [MPa] feq(0.6-3) [MPa] L’: Length of the central portion of a beam where no traditional reinforcement is necessary. L: Total length. RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 57/20 57 Giovanni Plizzari Examples of Shear Design: II 2Ø8@300mm 2Ø6@300mm Plain concrete 2Ø6@300mm FRC The introduction of fibers is industrially convenient, cost-effective and time-saving when the design process can be suitably optimized. RESISTENZA A TAGLIO DI ELEMENTI IN C.A., C.A.P. E F.R.C. Milano – June 17°, 2015 58/20 58